Lelit Bianca V3 Dual Boiler Espresso Machine

$2,999.95

- For more information, please see Terms & Conditions.

- Defects due to limescale buildup are not covered under warranty. Please read about Limescale Prevention.

- For any issues within your warranty period, please contact us.

- Standard ground shipping within the contiguous 48 states. Alaska & Hawaii shipping costs extra.

- Total order must be over $99 after all discounts.

- For more information, please see Shipping Included.

- Must be logged into your online account when purchasing to accrue EspressoPoints.

- For more information, please visit EspressoPoints.

┌ Special Deals ┐

"Build Your Espresso Bar" with accessory discounts!

Frequently Bought Together

V3 changes:

New software update which includes:

- Low Flow function

- Stand By mode

- Brewing Temperature Offset

- Faster warmup time

Want to upgrade?

Discover the pinnacle of espresso craftsmanship with the all-new Lelit Bianca V3. If you're seeking an upgrade from your current Lelit Bianca, now is the time to experience the latest advancements. Immerse yourself in a world of choice as the Lelit Bianca V3 is available in three exquisite colors: Stainless Steel, Black, and White. Unleash your inner barista and elevate your espresso game with this stunning machine that effortlessly combines innovation, style, and unrivaled brewing performance.

Lelit Bianca Version 2 Changes, as of 6/3/2021! (2021.5)

Extended Steam Valve and Hot Water Valve

The steam valve and hot water valve have been extended in length to place them further away from the front panel of the machine. This upgrade facilitates more side-to-side movement of the wands.

Water Tank

The water tank's appearance has changed slightly and includes the new Lelit logo on the side of the tank.

Filter Baskets

The Bianca now includes the Lelit by IMS filter baskets.

Internal Changes

One of the two safety thermostats on the steam boiler has been updated.

Lelit Bianca Version 2 Upgraded Features, as of 1/20/2020!

Instant Stand-By Sleep Mode

By holding the plus and minus buttons simultaneously for three seconds on the LCC display, the machine will go into sleep mode. Please note the LCC must have sleep mode 'on' in the menu for 30, 60...up to 540 minutes. This is just a quick way to get the machine into standby mode where the coffee boiler stays at 80 degrees C and the steam boiler is off.

Reserve Mode for Water Reservoir

The machine can perform the espresso extraction while the water level is low in the reservoir. Also, if the water level in the reservoir is just above the low water indicator, the extraction will continue for 60 seconds after the LCC indicator shows low water. Thus, this will save the espresso shot!

Instant Economy Mode for Powering Coffee Boiler Only

By holding the minus button for three seconds, users can deactivate the steam boiler and maintain the programmed temperature of the coffee boiler.

Actual Boiler Temperature Display

Press the LCC plus button on the right side ONCE quickly and hold to see the current coffee boiler temperature. Press the LCC plus button TWICE and hold quickly to see the actual steam temperature.

Shot Clock Timer Display Delay

At the end of extraction, the shot clock time will continue to show on the LCC for 20 seconds.

Steam Temperature

- The maximum steam boiler temperature increased from 125 degrees C to 135 degrees C (266 degrees F to 275 degrees F).

- The minimum steam boiler temperature on both V1 and V2 are consistently 115 degrees C (239 degrees F).

- No change is necessary for the safety valve on the steam boiler! In fact, the boiler and boiler safety valve for 3 bar allow increases on the version 1 espresso machines.

All About the Lelit Bianca Dual Boiler Espresso Machine!

The PL162T Bianca from Lelit is their newest luxury dual boiler espresso machine. After over two years of studying with a well-known espresso academy in Italy, many baristas, and professionals, including 1st-line, the Lelit Bianca espresso machine was built from the ground up and designed for flow control through the brew pressure paddle. There are many secrets learned from the two years. In fact, one of those secrets of the espresso academy was the precise range of flow to create the best espresso.

Thus, we can certainly say that the Bianca is more than just a flow control device slapped onto an L58E espresso machine. Since September 2018, our customers started switching out their $8000+ espresso machine for the Bianca! Don't be fooled by Lelit's advertising if you are not a barista...

With the Bianca, Lelit continues to outdo themselves and now leads the industry with the widest range of prosumer models. However, although the Lelit Bianca can be a beginner dual boiler espresso machine, it packs some of the best technology that will make any barista jump for joy. In other words, the Bianca has really disrupted the worldwide prosumer espresso machine market. This is all thanks to its manual brew pressure via flow control as well as its external reservoir! In fact, the needle for the flow control is made of stainless steel and the gicleur is made of brass. This prevents galling between the same metals under intense heat.

More about the Lelit Bianca

Not only does the machine include a PID-controlled dual boiler, for those who are looking to experiment with pressure profiling/flow control seeking the Holy Grail; but, sitting on top of the legendary L58E grouphead is a wooden paddle that allows the user to manually adjust the brew pressure (control the flow of water) as the espresso shot is extracting! All are under 16" in height! No need to pre-program it with your fingers crossed that your flavor profile will be to your liking. You have the control, right at your fingertips with a brew pressure readout at the group! And, the wooden paddle diffuses the high intense heat emanating from a super hot L58E grouphead. Thoughtful design by Lelit!

Clean design inside and out! Nice curves make Bianca look super sexy! Unlike other machines with multiple body panels, the Bianca affords one easy wraparound body panel to gain inside access. Inside, all wiring and layout are superbly placed for performance and easy repair. Even 2 bottom port holes for access to both heating elements in the powerful boilers.

Finally, after working with Lelit for two years on features and design, we (as of March 2018) have the prototype in our showroom for testing and feedback to the manufacturer. We are running it 24/7 and trying to break it! In addition, customers can make an appointment to see the machine in action in our Freehold, NJ location.

The Lelit Bianca Dual Boiler Espresso Machine is beautiful in design and proves to be awesome in what she produces in the cup! Light roast, no problem! City roast, no problem! Dark roast, definitely not a problem! The paddle on top of the grouphead allows on-the-fly brew pressure profiling while you are watching the extraction and brew pressure gauge.

With dark roasts, you can smooth out the flavor of a spring piston lever machine that starts off with high brew pressure, then diminishes throughout the shot. With city and full city roasts, use a low-pressure profile to extract pure sweetness. Moreover, on light roasts, experiment with any of your imaginary brew pressure profiles to find the best flavor in the cup! On June 4th, 2019, a customer said "Bianca makes stupid good coffee!" It is so true, with a good grinder, the espresso that comes out is amazing!

Another innovative design component! The external AND movable reservoir that does not heat when the machine operates for hours as other machines do. Furthermore, the Bianca has a water reservoir that can re-position on either side of the machine to suit your needs and your countertop. Don't want a tank? No worries! The Bianca is directly plumb-able too, (even the drip tray is drainable!) All of these features are in a stainless steel body, with accents by wooden handles, feet, and lever.

Forget your shot timer! The Bianca has a shot timer in its LCC. The shot timer continues during the programmable pre-infusion and programmable soak time!

The Lelit Bianca was selected as one of the top 12 most innovative products at the 2019 Florida Restaurant & Lodging Show

- Furthermore, this was against not only espresso machines, but also various food and drink recipes and equipment as well! Thanks to the Bianca's game-changing manual brew pressure profiling, the espresso came out as perfect as it can get!

Bianca won 3rd place Best New Non-consumable Product at Coffeefest NYC 2019

- This was impressive against all new products, not just espresso machines. The 1st L58E grouphead espresso machine with manual brew pressure profiling uses flow control during the extraction!

Do you want more information? Please read an independent UK review made for the Bianca. However, although there are a lot of details, please keep in mind of differences in performance, like warm-up times being faster under 220 volts, or other small differences that may be made for the UK market, or changes in packaging, etc by the manufacturer for the UK market.

If you wish to have your machine turn on and off automatically or have your phone control it, we strongly suggest using Wemo as the preferred smart plug (minimum 15 amp rating) from your favorite mass-market retailers. Many of our Bianca customers have successfully used Wemo smart plugs without any incidences to date. We are glad Lelit did not program a built in timer because then there would be no phone control to turn the machine on.

If you're looking for a grinder that pairs well with the Bianca, the Lelit Fred is a great choice!

-

Bianca & Sheila - Customer Walkthrough (Pt 1 of 2)

Sheila has been a long-time customer of 1st-line, and she finally decided it was time to upgrade her espresso setup to a Lelit Bianca! We thought this would be the perfect opportunity for Java Jim to take us all on an in-depth look of this amazing machine.

-

Bianca & Sheila - Customer Walkthrough (Pt 2 of 2)

Sheila has been a long-time customer of 1st-line, and she finally decided it was time to upgrade her espresso setup to a Lelit Bianca! We thought this would be the perfect opportunity for Java Jim to take us all on an in-depth look of this amazing machine.

-

Tank Removal & Getting Inside

The Bianca tank is fairly easy to reposition to whatever side you choose to fit your space, or remove completely for a direct cold water line into the machine. Removing the body panel isn’t too difficult either, as Jim shows us and goes over some of the features inside this machine that we love.

-

TechTips: Lelit Bianca: Change E61 Grouphead Gasket

Learn from Java Jim how to change your grouphead gasket and dispersion screen! Today, he is using the Lelit Bianca, which is super important to change every 6-12 months depending on how much you use it.

-

Lelit Bianca: New UPS/FedEx Packaging!

JavaJim at 1st-line Equipment reviews the exceptional new packaging for the Lelit Bianca espresso machine and how we can ship it via UPS (or FedEx Ground). This allows you to ship your Lelit Bianca espresso machine to your home, office, or other address.

-

Lelit Bianca Pressure Profiling Standard 9-Bar

Learn from Java Jim how to achieve the optimal 9-bar extraction for your espresso using the Lelit Bianca!

-

Lelit Bianca Pressure Profiling Spring Piston Lever

Learn from Java Jim how to add variety to your espresso extractions with your Lelit Bianca!

-

Lelit Bianca Pressure Profiling Wow! 114 Second Espresso Extraction!

Java Jim discusses the 114 second espresso shot and goes through the lengthy extraction process, so you can learn to do the same at home!

-

Lelit Bianca: Secret Feature

Java Jim shares a newly discovered feature on the Lelit Bianca!

-

Lelit Black Wood Kit with the Lelit Bianca

Java Jim updates his Lelit Bianca with new knobs and accessories from the Lelit Black Wood Kit! What do you think?

-

Making the Plumbing Connection for Lelit Bianca

Learn from Java Jim how to make the plumbing connection for Lelit Bianca!

-

Our Best Dual Boiler Espresso Machine of 2020

Learn from Java Jim about our bestselling dual boiler espresso machine of 2020!

-

Overview: Lelit Bianca Version 3 Espresso Machine

Learn more from Java Jim on the new upgrades on the Lelit Bianca V3 Espresso Machine

-

Lelit Bianca V3 - Really A Quicker Warm Up Time?

We bench tested the Lelit Bianca Version 3 espresso machine with 124 volts of electricity and about 76 degrees F ambiente room temperature, and it surprisingly heated up very quickly! How fast? Learn more by watching the video. Please note that wattage as low as 100 volts in your outlet or colder or warmer room temperatures may impact the speed of time to warm up the Lelit Bianca V3 cappuccino machine.

Introduction

Indulge in the ultimate espresso experience with the Lelit Bianca Double Boiler Espresso Machine. This magnificent machine combines elegance and performance, boasting dual boilers for simultaneous brewing and steaming, allowing you to effortlessly craft exquisite espresso shots and velvety milk textures. With its innovative paddle-controlled flow profiling system, the Bianca puts the power of customization at your fingertips, enabling you to explore a world of flavor possibilities. Elevate your home brewing setup with the Lelit Bianca and enjoy the art of espresso like never before.

Special Features

L58E Grouphead with Flow Control

The L58E grouphead ensures consistent water stability. Hot water circulates from the boiler through the grouphead and back. The result? The grouphead and your portafilter stay nice and hot, especially important to get a great shot of espresso. A lever next to the grouphead easily activates the pump to draw water through the coffee grinds.

Control Brew Pressure on the Fly! A 1st for any L58E Grouphead

The wooden paddle and brew pressure gauge on top of the grouphead allows full manual control over the brew pressure (through control over water flow) as you are pulling your shot of espresso. Create different flavor profiles to your heart’s content!

Reservoir: Pick a side, any side!

Have you ever seen an espresso machine that gives you a choice where to put the water reservoir? Well, the Lelit Bianca does! An even bigger benefit is that when the reservoir is on the outside, the heat built up on the inside of the machine is not heating the water in the plastic reservoir. The heated reservoir water on other machines can change the thermodynamics of the water entering the coffee boiler and thus the water going through the grouphead.

Even better, it also allows users to directly plumb it in, including the drip tray. When plumbed in, the reservoir assembly can be removed to save precious counter space.

PID and Dual Pressure Gauge

Lelit adds their sophisticated PID system, that allows timed preinfusion, a reference timer, and a low-water level alert. A dual-pressure gauge on the other side of the machine measures both the boiler pressure (0-4 bar) on top and pump pressure (0-16 bar) on the bottom.

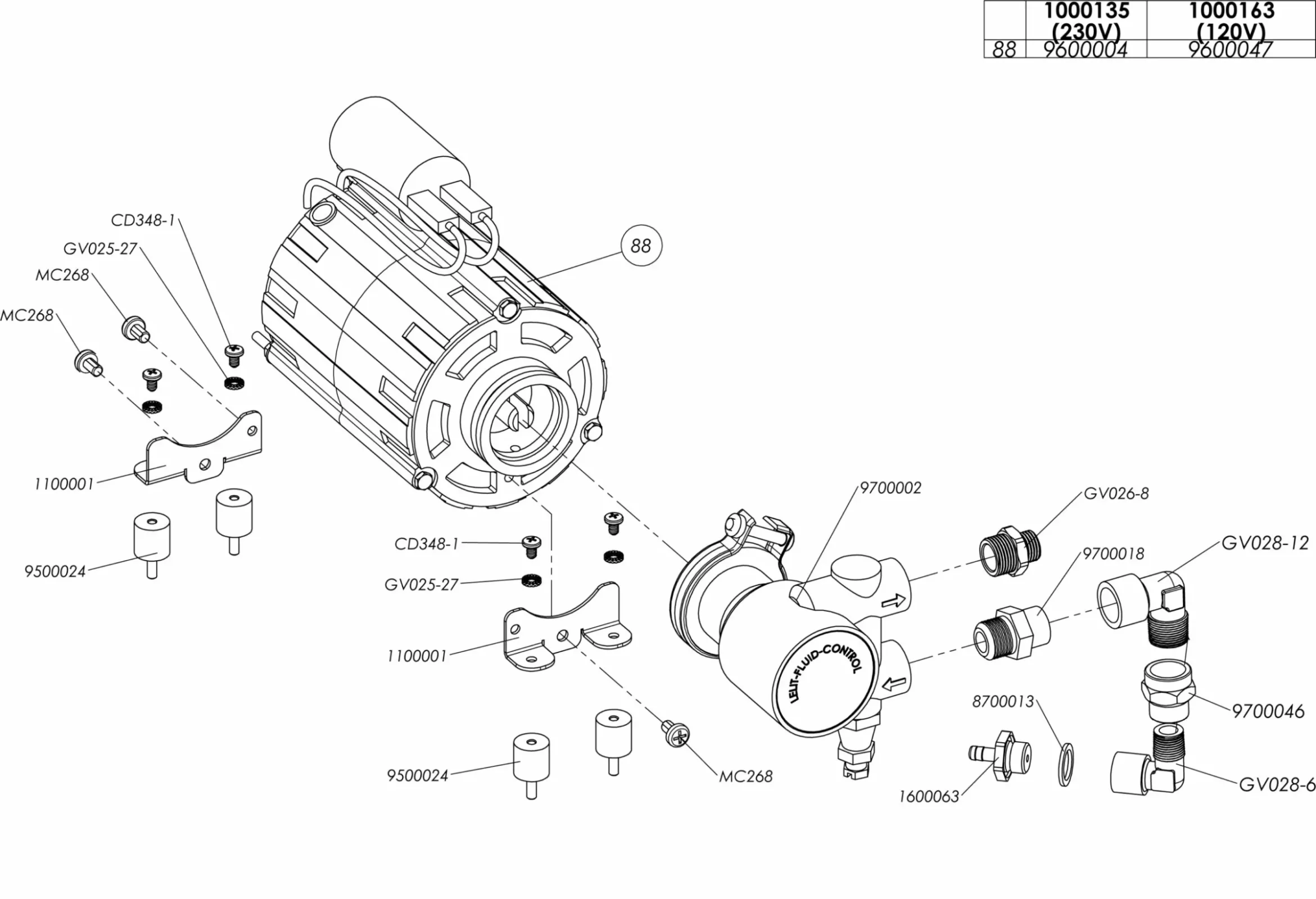

Rotary Vane Pump and Motor

Produces a quieter extraction than a vibratory vane pump and much quieter than the ‘whiney’ gear driven pumps found on other brew pressure profiling espresso machines. You can make adjustments underneath the espresso machine.

Additionally, the rotary vane pump is so much more reliable than gear driven pumps. Gear driven pumps have magnetic drives which tend to fail sometimes in the first 3 months of ownership.

Steam and Hot Water Wand

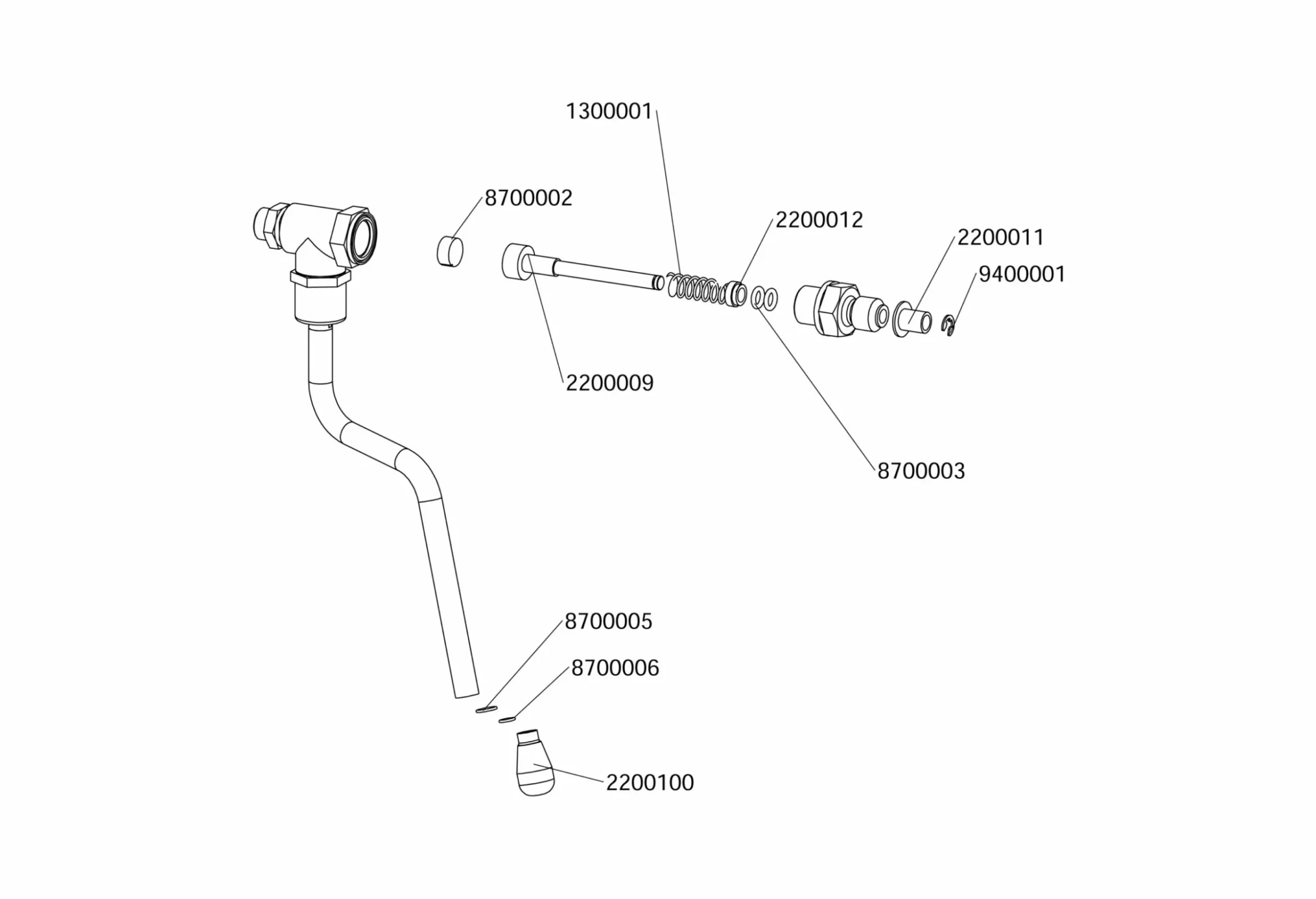

Allows for more flexibility. Rosette-style knobs control the separate steam and hot water wands, which are multi-directional. Moreover, the steam wand comes with a 2 hole steam tip (1.5mm holes). Hidden in the accessory box is a 2 hole tip with 1.0mm holes for those needing to froth fewer amounts of milk.

The wands are no-burn to the touch. Insulation on the inside allows you to move the wands easily to find the perfect angle you are seeking.

The Lelit Bianca powers some punch with steam power by programming the steam boiler up to 266 degrees Fahrenheit. In fact, two tips are available with the machine. The smaller 2 holes with 1mm openings were included for those who wanted to steam with less power.

Built with Quality Components

On the outside, the Lelit Bianca shines with stainless steel body polished to a mirror finish. Also, in the inside, it has two insulated stainless steel boilers with copper tubing connecting the boilers to the grouphead or valves. The 0.8-liter coffee boiler is matched to perform well with a 1000 watt heating element, and the steam boiler integrates very well with a 1400 heating element to pack a great punch of steam power!

Wooden Elements

3-cup bottomless portafilter with smooth wooden handle included with the machine. The 3 cup baskets can hold up to 22 grams of ground coffee (this depends upon the type of coffee and grind fineness as coarser grinds or lighter density coffees may less the 22-gram capability).

The dual spout portafilter also has a very nice wooden handle and two forward streaming spouts for easier espresso extraction viewing.

Less plastic is always a bonus in our eyes. In addition to the portafilter handle wood crafted, the Lelit Bianca also has wooden accents on steam and hot water knobs, lever, wooden paddle, and feet! Furthermore, the wooden paddle on top of the grouphead diffuses the heat that builds upon the grouphead.

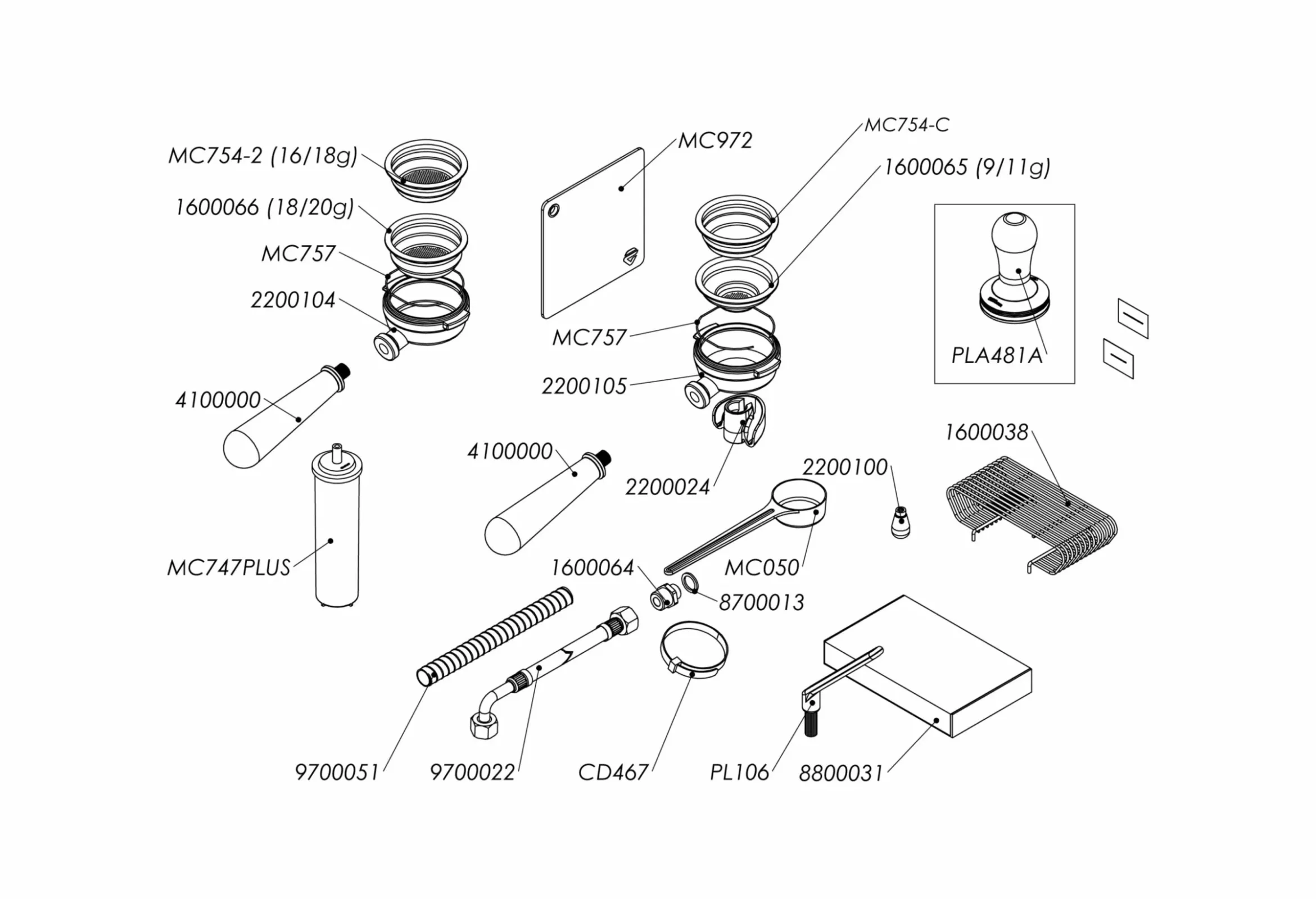

A Whirlwind of Accessories!

- Instructional manual – Please read this manual first!

- Stainless steel inlet water hose – ~4’10” L. Also comes with adapter fitting and gasket. If you are plumbing, please use only cold water with a backflow preventer and pressure regulator set to 35 psi.

- Vinyl waste drain hose – ~4’8″ L x 3/4″ OD x 1/2″ ID.

- Heavy stainless steel cup warmer grate – Sits above the top panel to prevent cup marks.

- Rechargeable water softener filter – Good for up to 70 liters of water before recharge. Replace once a year.

- Cleaning cloth – Nonabrasive antibacterial microfiber. Helps to remove smudges and stains on the body panel.

- Stainless steel cover – For the water tank.

- 58.55mm stainless steel tamper – No need to purchase a new one.

- Extra steam tip – With 2 holes. Each hole measures ~1.0 mm.

- Bottomless portafilter – Wood handle and stainless steel 3-cup filter basket.

- Dual spout portafilter – Wood handle and stainless steel 1-cup filter basket and 2-cup filter basket.

- Stainless steel blind filter basket – For backflushing. Effective March 30, 2020, a blind filter holder slot is built into the frame below the drip tray.

- Plastic grouphead cleaning brush – With nylon bristles to clean grouphead gasket.

- Plastic scoop – If you are using ground coffee.

- Stainless grate platform – Place over drip tray grate if you are using espresso cups or shot glass.

- Accessories on the machine – 2.5-liter removable water reservoir, stainless steel drip tray & grate, and effective March 30, 2020, the four-hole steam tip replaces the two 1mm holes steam tip.

-

- You will find the nozzle with two holes at 30° and 1mm of diameter (22/100) directly assembled on the machine. The nozzle with four holes at 60° and 1mm of diameter (22/108) will be positioned in the supply box.

-

Espresso Machine Warning:

- ELECTRICAL WARNING: To avoid electrical damage to this espresso machine which is not considered a manufacturer's defect, please acquire and install a single-outlet surge suppressor rated at 1080 joules or higher. the lack of the recommended surge suppressor, the espresso machine can be damaged at the power switch, the electronics, the heating element, the pressurstat or the wiring inside.

- WATER WARNING: To increase the useful life of and not damage your espresso machine, please use softened water. Softened water is water without calcium and without magnesium, but still has other minerals for espresso extraction. Do not use distilled water, purified water, nor reverse osmosis water as these types of water create oxidation with the metals and cause the same damaging effects as limescale.

- DESCALING WARNING: We do not recommend descaling unless there is an issue with the espresso machine. The reason is that too much descaling can eat away at the metals and gaskets inside an espresso machine.

- Before Shipping: Please note that every Bianca is bench tested for 24 hours. There is a 24-48 hour process on weekdays. This means Friday 12 noon to Monday 11 AM EST does not count. There will be a delay between placing your order and receiving a tracking number.

- Shipping:

- As of August 1, 2019, all Bianca’s are shipping regular UPS ground.

- V3 models started shipping in July 2022.

- Receiving:

- If there is any box damage, please immediately note it on the UPS signature line. No notation means you accept the shipment in good order.

- If the machine arrives wet, please allow to air dry for at least 24 hours before plugging in. All units are drained after testing but not all the water can be removed. Some water may dislodge during shipping.

- If there are any concealed damages or defects found once outside of the box, please notify us within 5 business days.

- In any case above, please keep the original box and packaging if the unit must be shipped back out.

- Warranty: Please note any shipping to or from 1st-line Equipment (including under warranty) is not included. If at all possible for the customer, it is best they save the original box & packaging.

Additional Information:

- Direct connect mode - There is a small plug underneath the machine that needs to be disconnected. This plug has the other wire going to the reservoir. In the machine accessories, there will be included a fitting cod. n.1600064 and gasket 8700013, which one needs to screw on the machine water inlet fitting to connect the machine to the mains water.

- Pre-infusion - In the Bianca, the pre-infusion works by programming the “Time ON: Xx S.” and “Time OFF: Xx S.” of the water pump. If Time ON is zero seconds, then pre-infusion is off and can be managed with the manual paddle.

- Once the pre-infusion times (both “time ON” and “time OFF”) have been programmed, the coffee dispensing begins: the pump will be activated for the previously programmed “time ON” in order to wet the coffee puck. Once the “time ON” has elapsed, the pump will stop working for the previously programmed “time OFF”. Terminating the “time OFF”, the pump will start working again.

- When extracting the espresso with the pre-infusion programmed, we recommend leaving the paddle, positioned completely to the right (maximum water flow) until the end of the pre-infusion time.

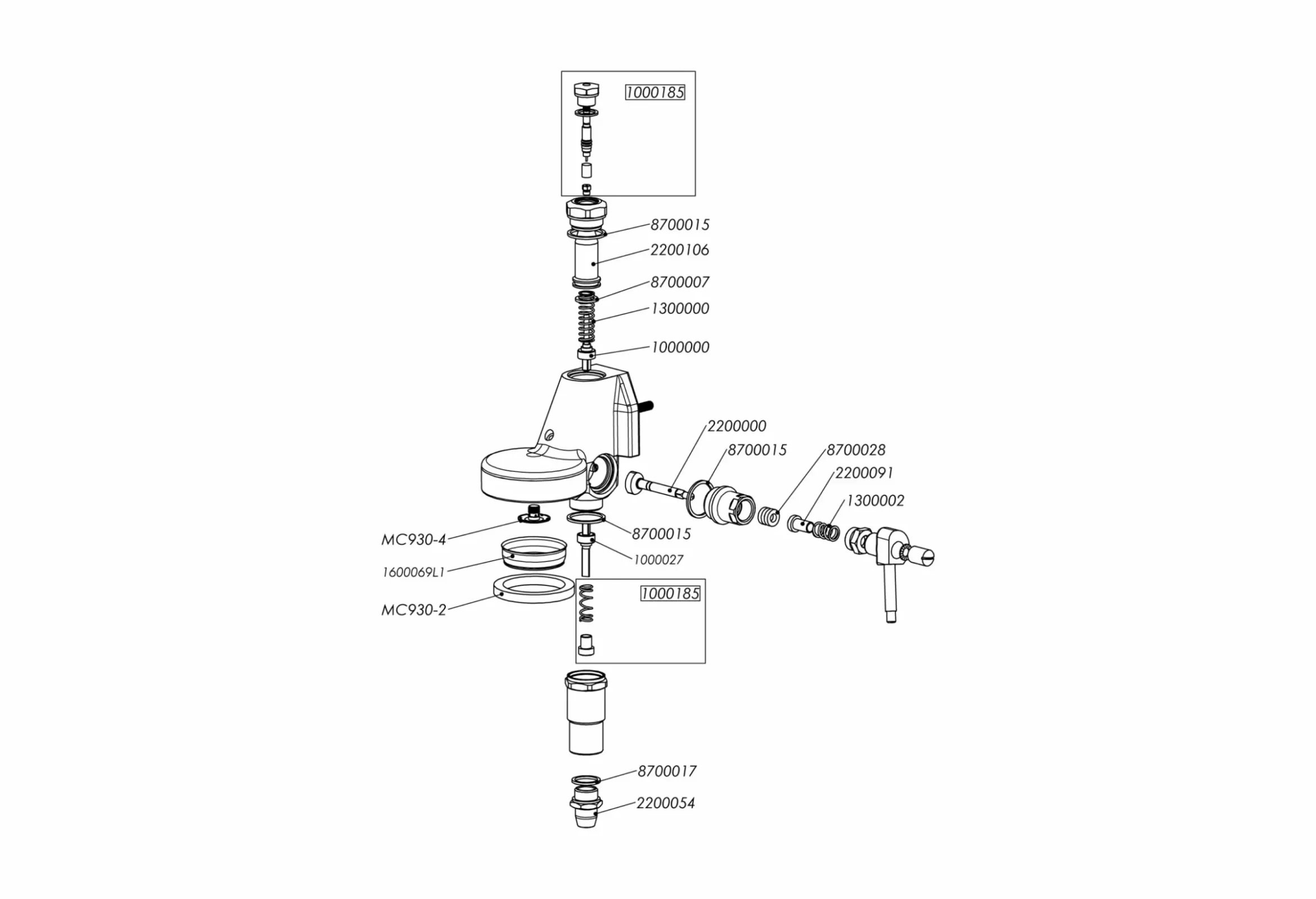

- The internal parts of the E61 brewer have been modified to eliminate the mechanical pre-infusion normally present in the standard E61 brewers.

- Pump - The pump is a standard rotary pump, with the screw on the bottom body to adjust the pressure.

- Brew paddle - When the paddle is completely in the left position, the water flow is totally closed. So, by moving the paddle we move up and down a needle which goes into the restrictor/gicleur by decreasing or increasing the water flow and the pressure on the coffee puck.

- Construction - The construction is robust and the machine is really heavy. The tubing is a traditional all copper tube construction, it has great component quality and the excellent boilers are in stainless steel.

- Change in design - Newer models will not have the elbow. The hose will be attached directly to the vacuum valve.

- Thread on each foot: M8x12mm

- Until further notice - Due to supplier issues, the 90-degree plug is now a straight 180-degree plug.

Specifications

| Brand | Lelit |

|---|---|

| Height (inches) | 15.625, approximate |

| Width (inches) | 11.5, approximate, PLUS 3.5 For Movable Tank |

| Depth (inches) | 17, approximate, including plug, PLUS 3.5 For Movable Tank |

| Weight (pounds) | 59, approximate |

| Wattage (watts) | Coffee – 1000, Steam – 1400 |

| Voltage (volts) | 120 |

| Boiler capacity (liters) | Coffee – 0.8, Steam – 1.5 |

| Portafilter size (mm) | 58 |

| Tank capacity (liters) | 2.5 |

| Country of manufacture | Italy |

Maintenance

Documentation

Common Parts

Technical Support

Warranty Information

Who handles the warranty

Eligible warranty for Lelit home equipment is handled by 1st-line Equipment or representative thereof. If you have purchased your Lelit equipment from another retailer (not 1st-line Equipment), you must contact them first in order to get your equipment serviced under warranty.

What does the warranty cover

The warranty is limited to manufacturer’s defects only.

Regarding espresso machines: Limescale buildup can lead to problems with your machine. The warranty will not cover any repairs if our technicians find limescale in your machine. Although descaling can be a good alternative to remove limescale causing minerals (calcium and magnesium), we strongly suggest that prevention is the best form of maintenance. The reason is that descalers can cause wear and tear on components inside an espresso machine. This includes gaskets, o-rings, and other metal components. However, where there is a clog somewhere, descaling will be a necessity on the specified part, area, or entire machine.

Regarding coffee grinders: As with all coffee grinders, it is very important to only change grind settings when the unit is powered on and the burrs are in motion. If you do not do this, the burrs will ‘gunk’ up and require cleaning by you every time this occurs. Changing the grind settings when the burrs are not in motion will render the grinder to only produce very coarse grinds or no grinds at all. If this result occurs, this will be considered operator error for lack of following directions, and not be classified as a defective grinder.

When does the warranty expire

The manufacturer’s warranty on new equipment is good for a period of 1 year from date of receipt which covers parts. Labor warranties may vary depending on the company you purchase from. Lelit products may have an extended warranty limited to manufacturer’s defect and will specifically state the extended period of time on your receipt.

Where will my equipment be serviced

In most cases, your Lelit equipment must be sent to a repair facility. If 1st-line Equipment will be servicing your equipment, you must either ship it or drop off at our facility in New Jersey.

How do I send in my equipment in for repair

If you are inside the warranty period and have purchased it from us, please contact us. Please be ready to provide the following information: invoice# of purchase, model of equipment, and a detailed description of the issue.

If you are outside the warranty period, whether you have purchased the equipment from us or not, please order a diagnosis. Please note that wait times can be up to 8 weeks. Our technical support staff can have a back log of repairs. As an alternative we have a listing of 3rd party repair companies across the USA that can assist you.

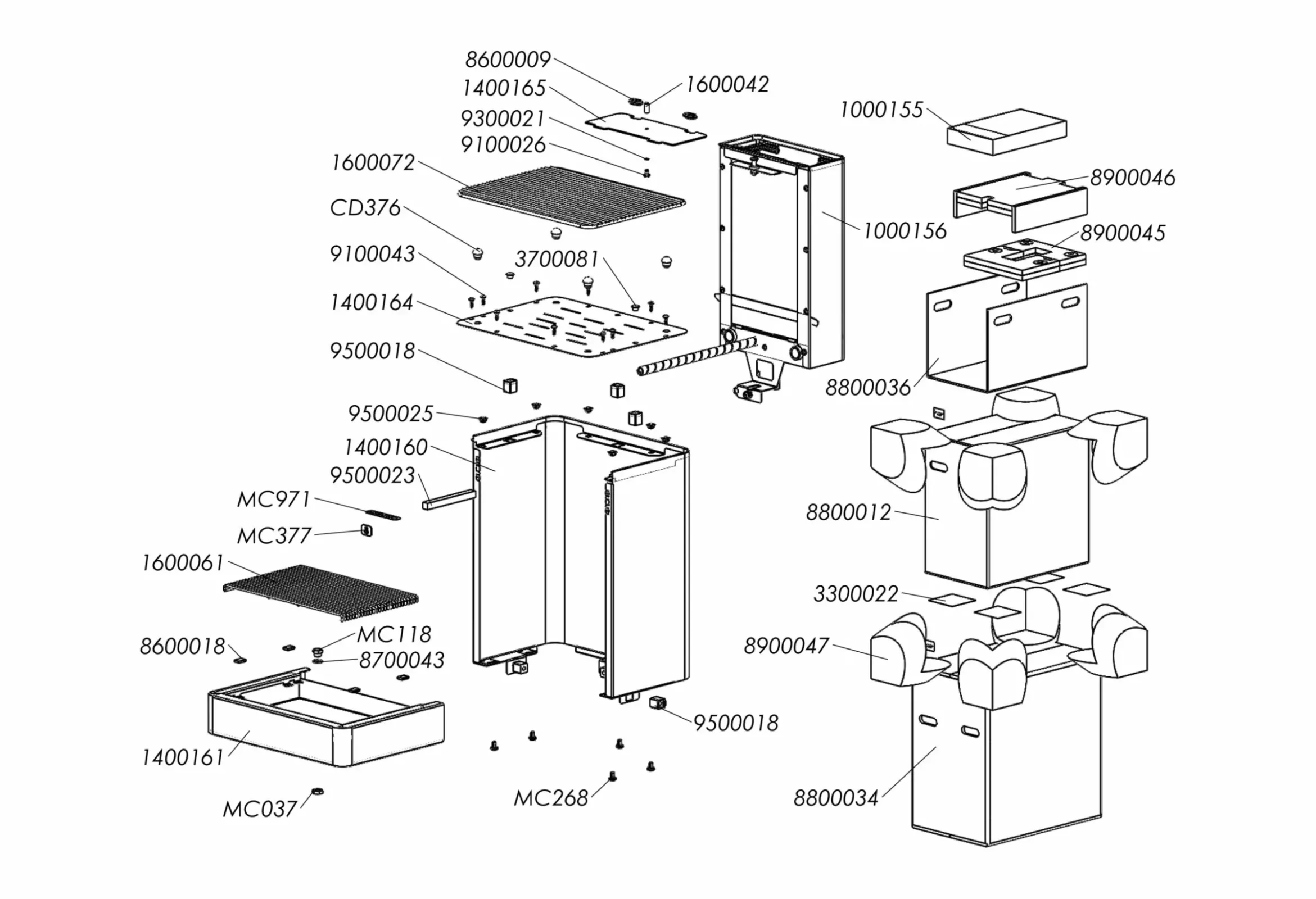

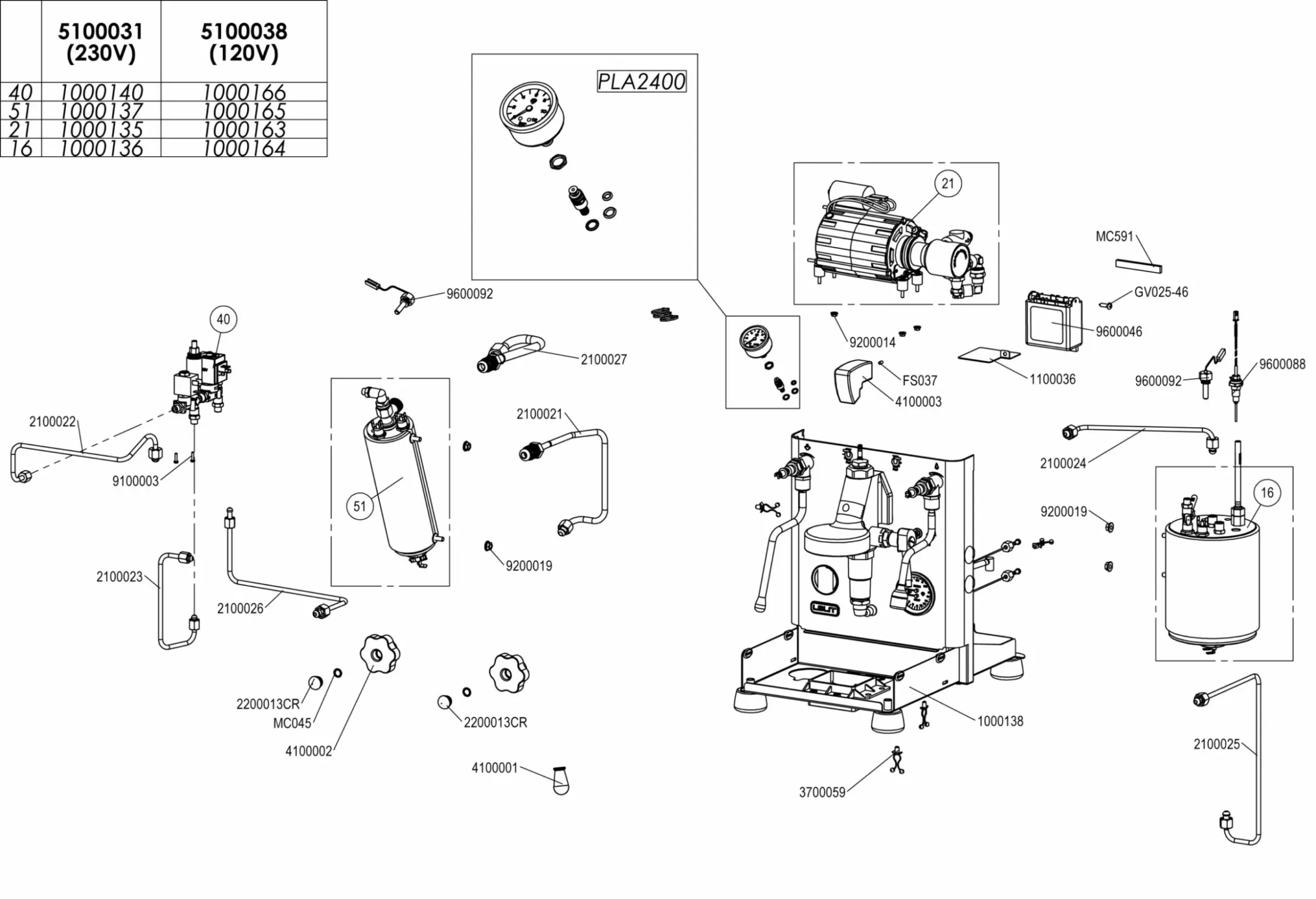

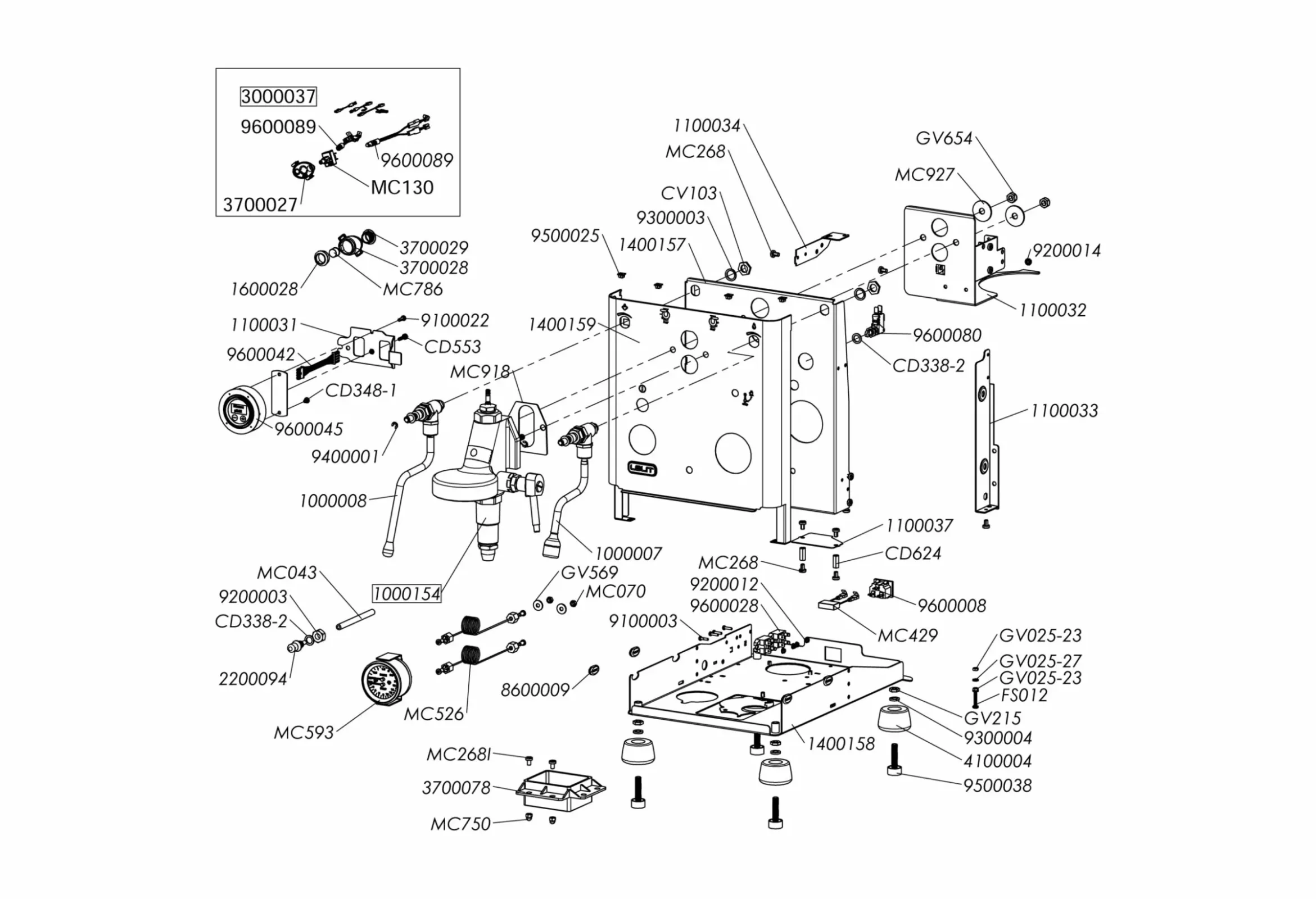

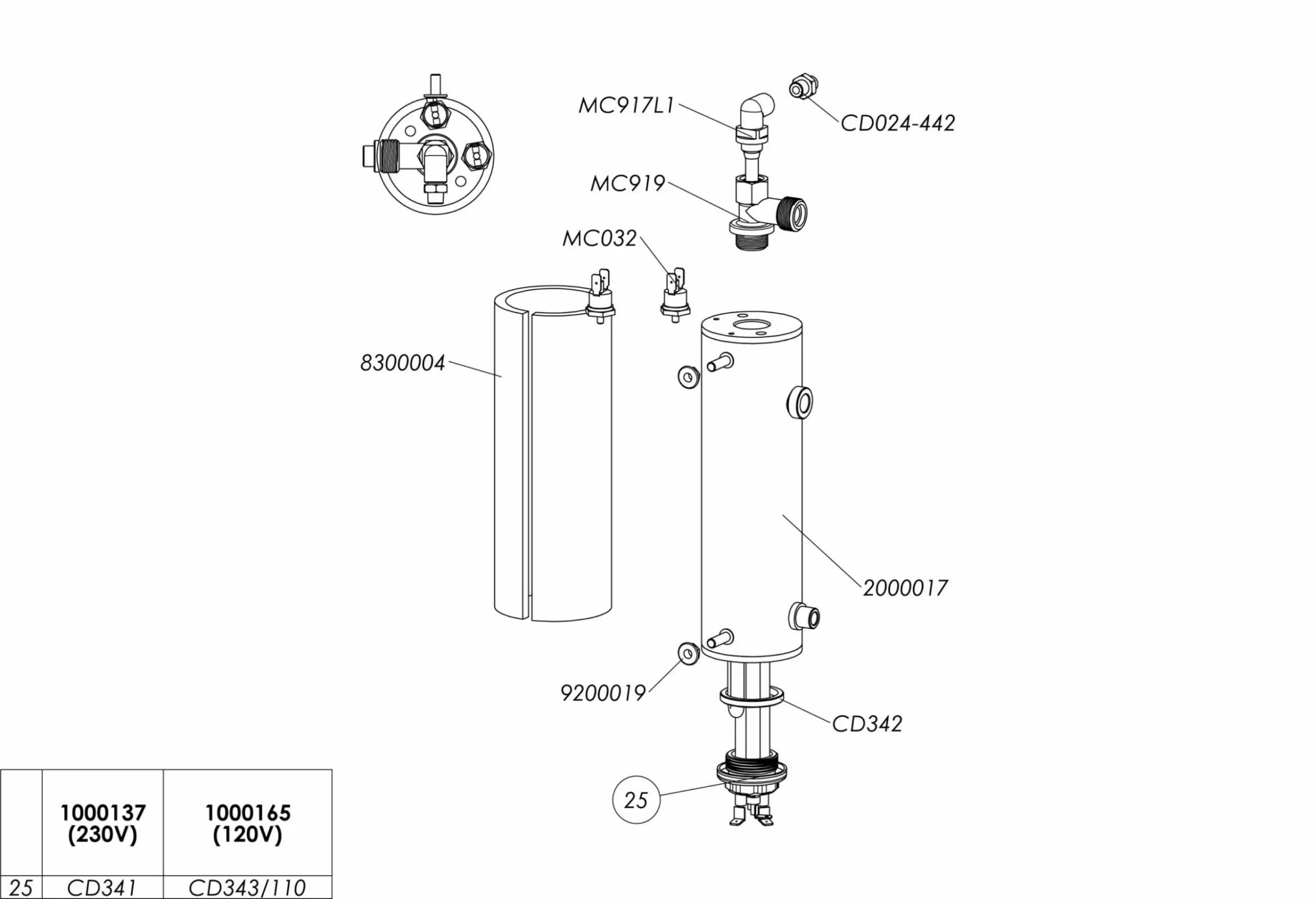

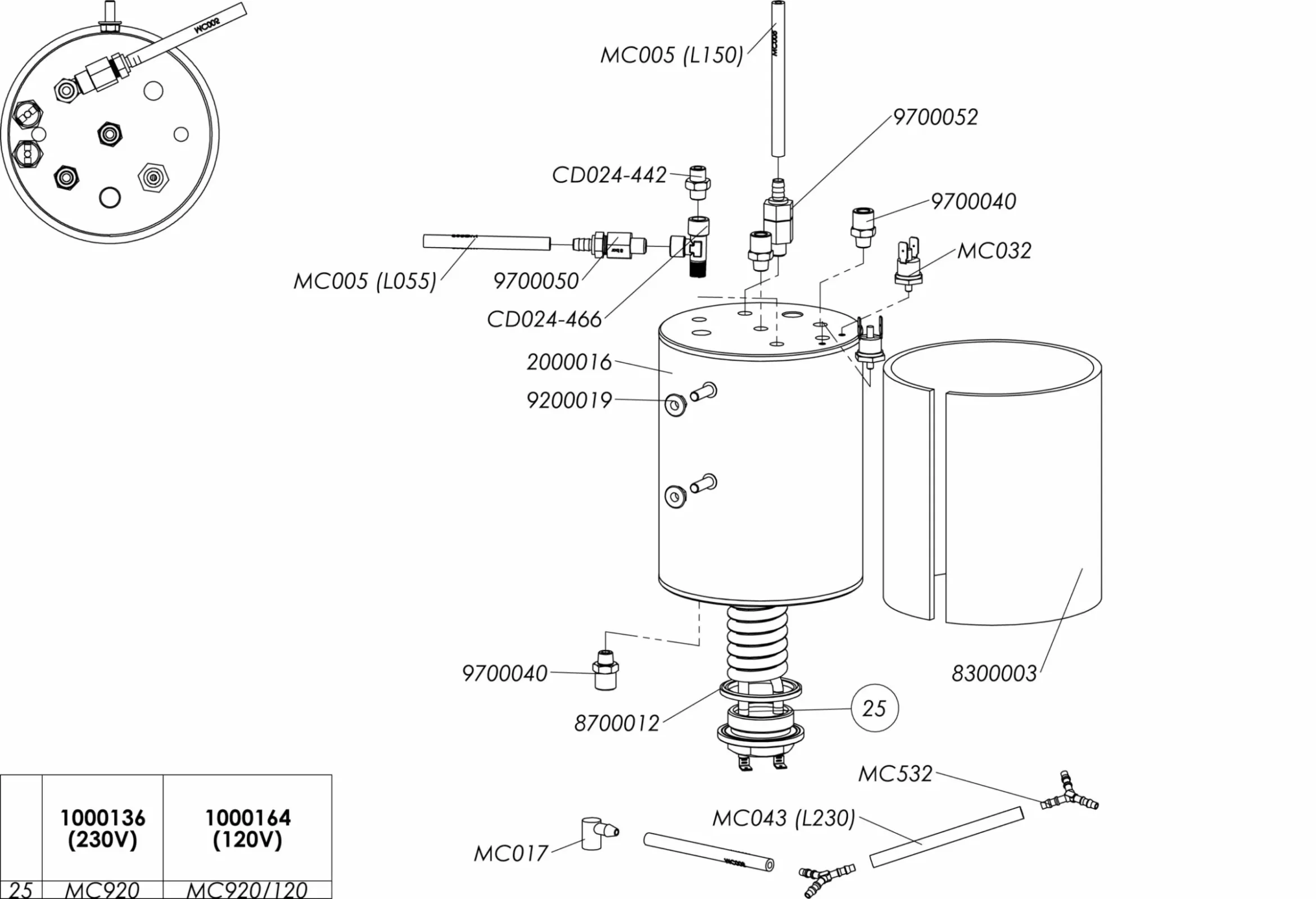

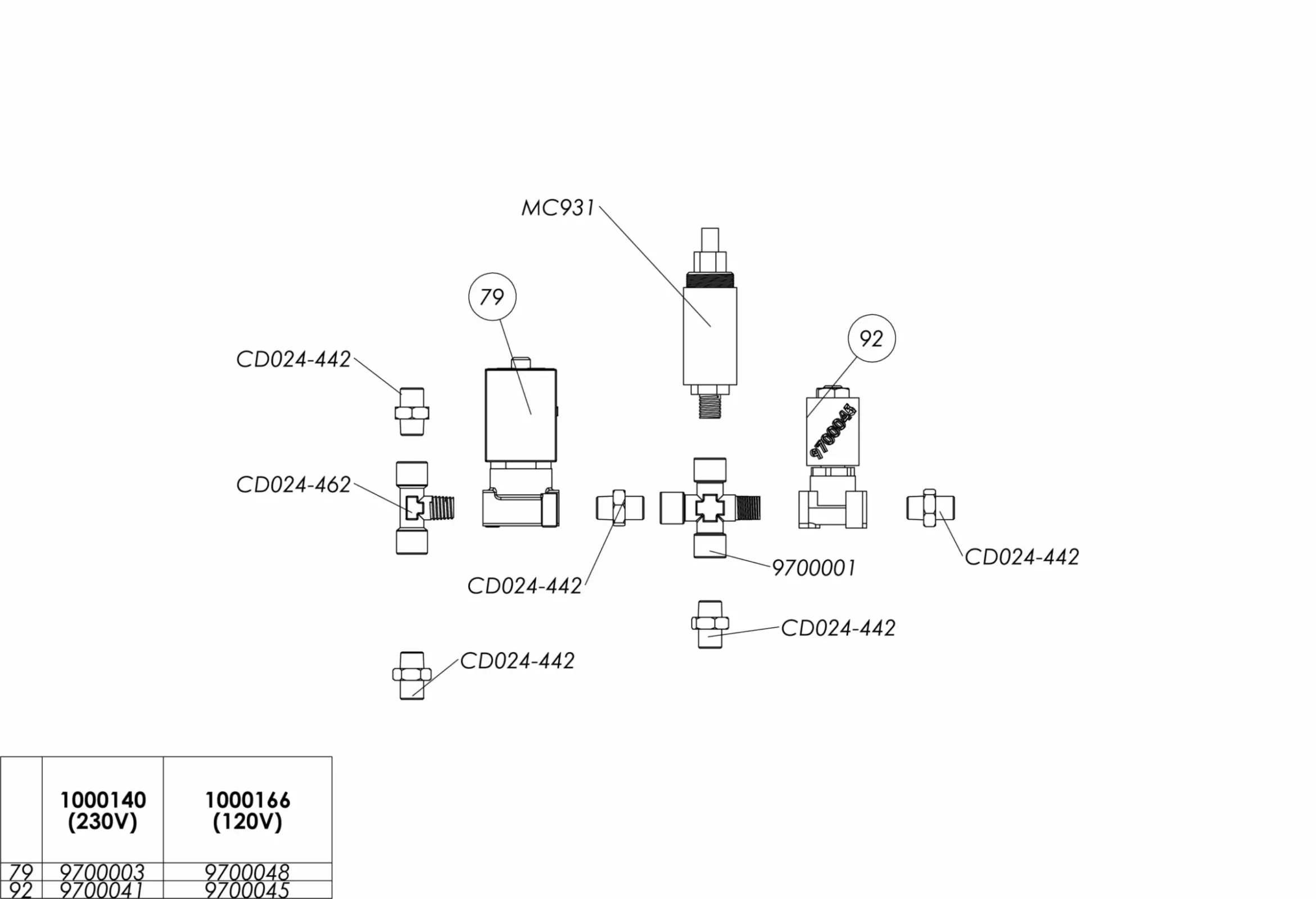

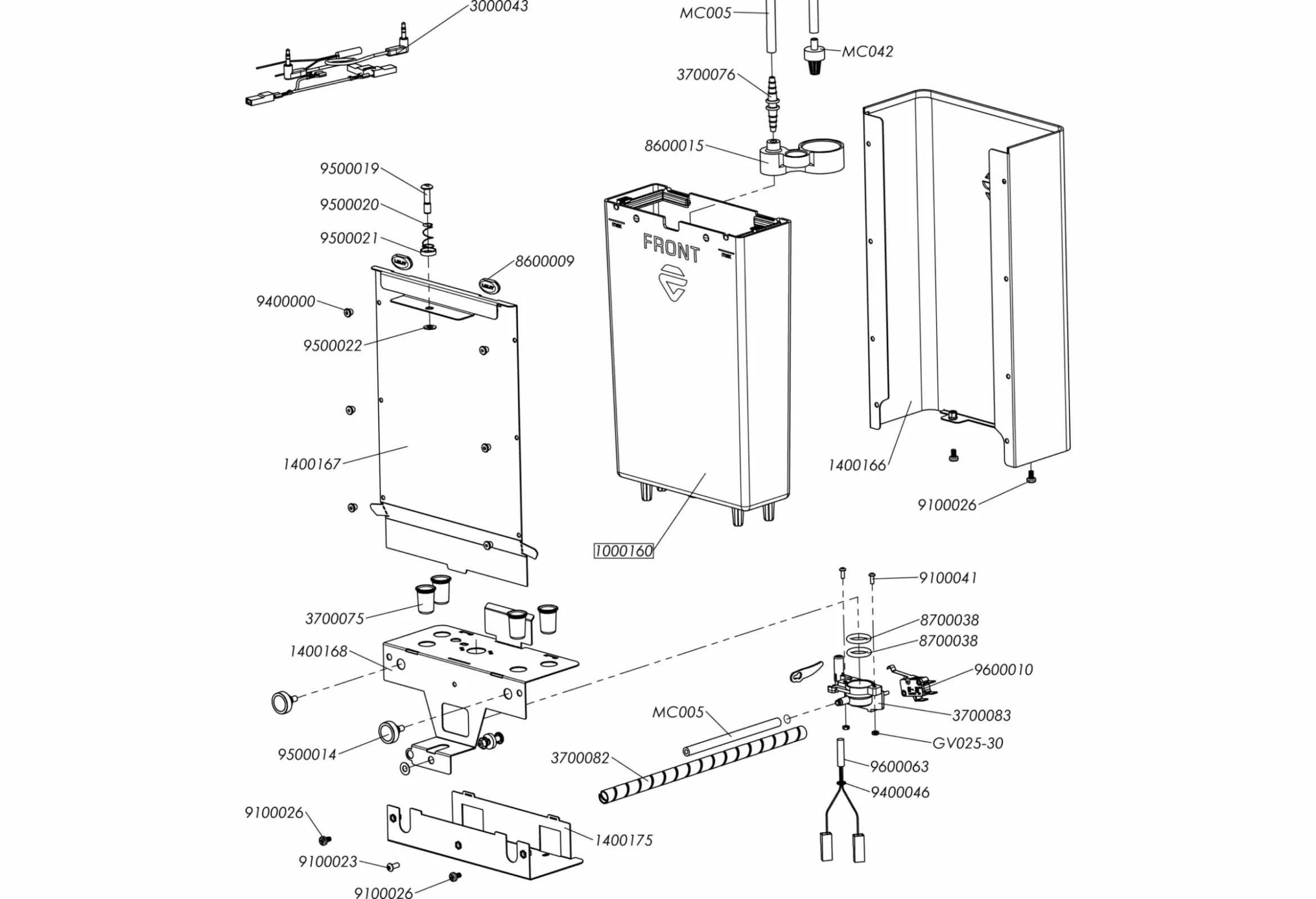

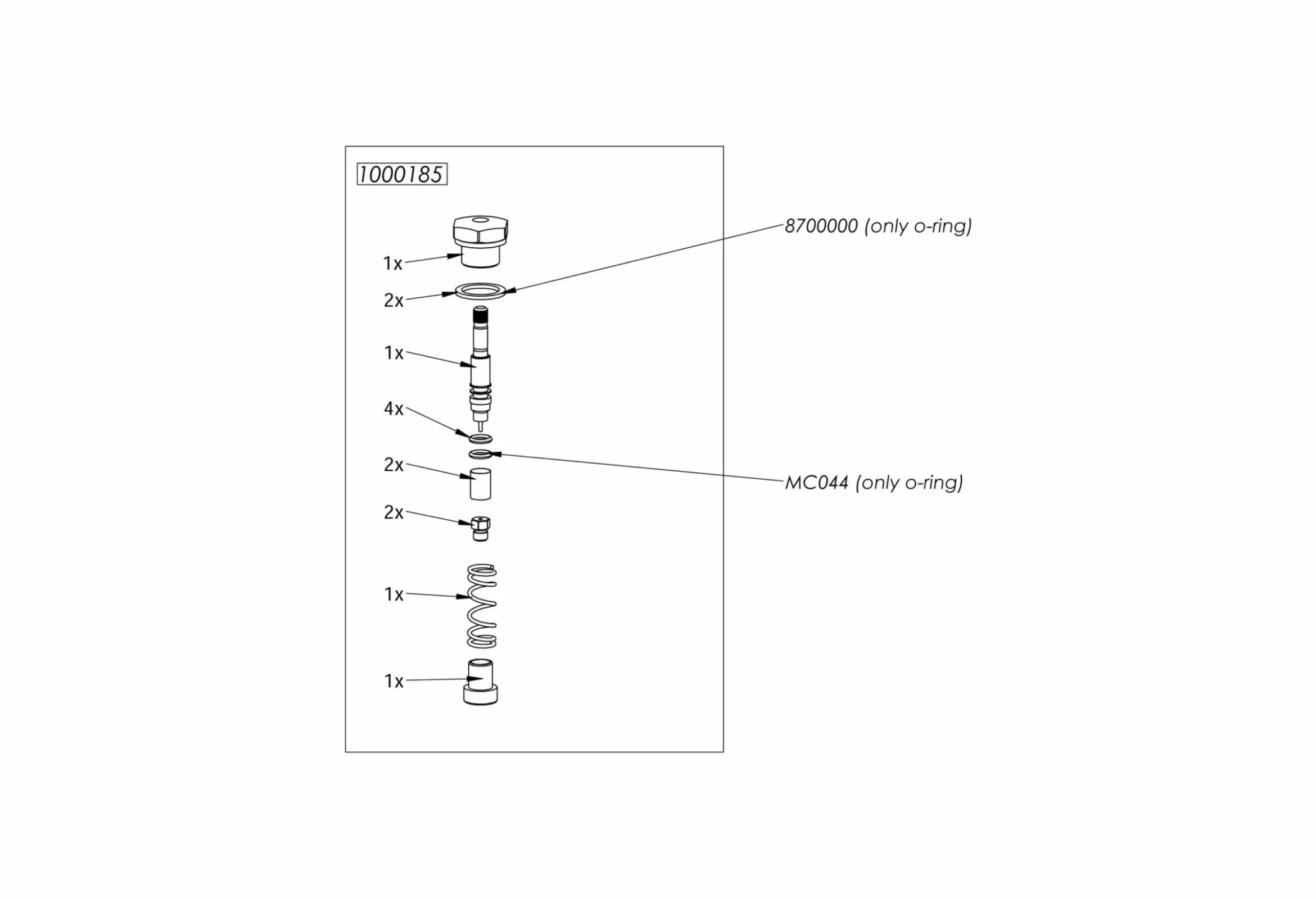

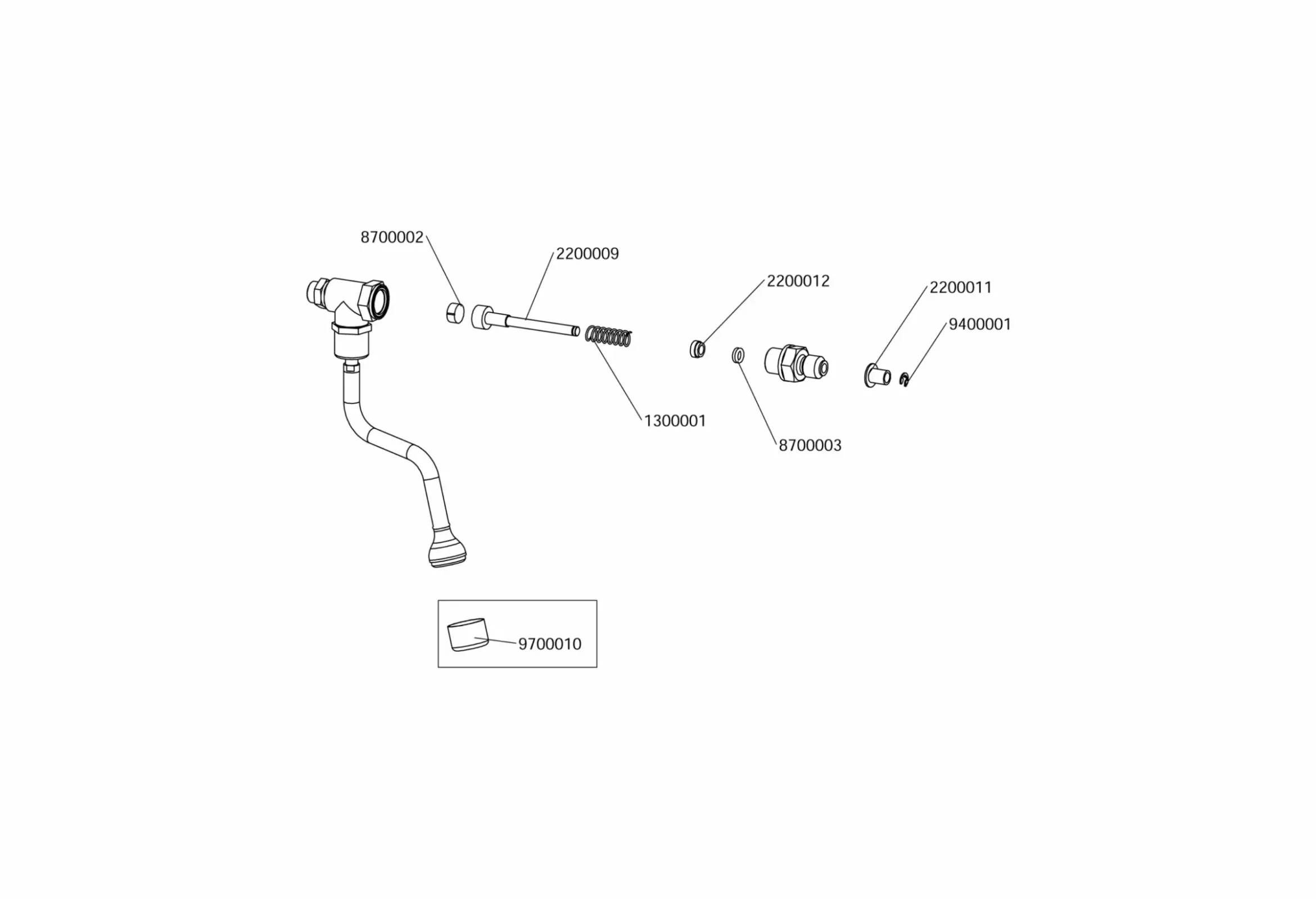

- Please use the parts diagrams provided below to determine the part(s) you need. Then use our search box above to find the part(s) on our website. If no results come up, more than likely we do not stock the part.

- If uncertain, please go to the equipment model or part product page. Then use the Q&A tab found on that web page to ask your question.

- Lastly, and only if the first 2 options were exhausted, please use our parts inquiry page.

- Our call center does not have the training to handle parts inquiries for over 60,000 different parts items. Asking any questions regarding parts will more than likely result in you being referred to the above steps.

- Please note also that all parts purchases are non-returnable or refundable and do not include technical support, instructions, or warranties as the purchase price of any part does not cover the cost of technical support. Technical support is available for repairing equipment in our shop.

- Sorry, we will only special order a part for a model we carry AND was purchased through our supply chain.

- Since we are unaware of the mechanical, electrical, and/or plumbing expertise of a parts buyer or the tools owned by a parts buyer, we are never able to advise if a self-repair can be performed.

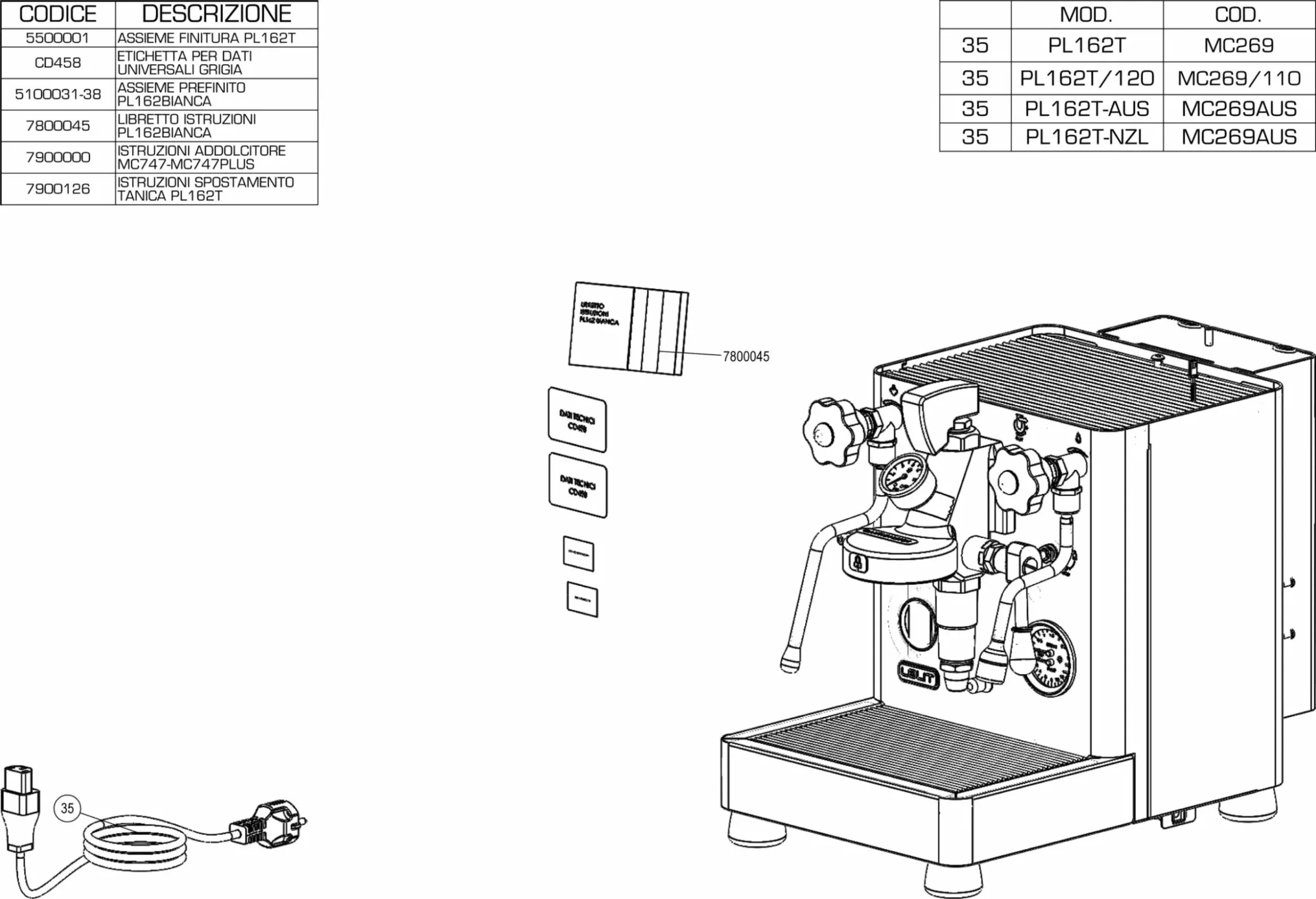

| 5100031-38 |

| 5500001 |

| 7800045 |

| 7900000 |

| 7900126 |

| CD458 |

| MC269 (230V) |

| MC269/110 (110V) |

| MC269AUS (AUS) |

| 1000007 | 9100003 | CV103 |

| 1000008 | 9100022 | FS012 |

| 1000154 | 9200003 | GV025-23 |

| 1100031 | 9200012 | GV025-27 |

| 1100032 | 9200014 | GV215 |

| 1100033 | 9300003 | GV569 |

| 1100034 | 9300004 | GV654 |

| 1100037 | 9400001 | MC043 |

| 1400157 | 9500025 | MC070 |

| 1400158 | 9500038 | MC130 |

| 1400159 | 9600008 | MC268 |

| 1600028 | 9600028 | MC268I |

| 2200094 | 9600042 | MC429 |

| 3000037 | 9600045 (V1, V2) | MC526 |

| 3700027 | 9600080 | MC593 |

| 3700028 | 9600089 | MC750 |

| 3700029 | CD338-2 | MC786 |

| 3700078 | CD348-1 | MC918 |

| 4100004 | CD553 | MC927 |

| 8600009 | CD624 |

Cup Collection

Porcelain cups with matching saucers. Imprinted with Lelit logo and Audrey Hepburn in a scene from “Roman Holiday.” Available in multiple coffee sizes.

Cleaning Products

Currently, Lelit offers a microfiber cloth which helps keep the surfaces of your equipment clean.

Knock Boxes/Drawers

Helps keep your area clean and eliminate trips to a garbage can.

Water Treatment Addons

Protect your espresso machine from harmful minerals that can result in limescale.

Customer reviews

Add a review Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Ask a question

Please ask follow up questions as a new question. Submitted questions will be first reviewed, answered, and lastly publicized.

-

I have a Bianca that I purchased in 2020 (I believe). Today, I pulled a shot and steamed milk for a latte. All functioned fine and results were perfect. Steam pressure good. Grouphead pressure good at the gauge. Boiler temp. good. Minutes later while making 2nd Latte, grouphead pressure dropped amid pull, steam pressure dropped and steam and water filled the drip tray under pressure through the little spout (I don't know what it's called), emptying the water reservoir. Now there is an intermittent but frequent dripping from the spout above the drip tray. What just happened?! Never seen this before. Steam pressure is 1.5 bar. I'll be shutting the machine down, letting it cool, starting it up again and seeing how it behaves when reheated.

-

Q I have a Bianca that I purchased in 2020 (I believe). Today, I pulled a shot and steamed milk for...... Read more answer nowAsked by Jonathan Peters on March 28, 2024 12:17 pmAnswered by the admin

This is only a guess. It sounds like the boiler refill probe is corroded and the steam boiler can not sense the water level. We suggest cleaning it. It could also be a bad bleeder and/or safety valve.

Answered by the adminThis is only a guess. It sounds like the boiler refill probe is corroded and the steam boiler can not sense the water level. We suggest cleaning it. It could also be a bad bleeder and/or safety valve. Unfortunately, this may need to be evaluated by a professional.

Hello, I've been having leakage from the drain valve that lasts even after coming up to temperature. I've already replaced the vacuum breaker and the Expansion Valve Seat and the problem persists. Any other ideas of what would be causing this?

-

Q Hello, I've been having leakage from the drain valve that lasts even after coming up to temperatu...... Read more answer nowAsked by Tyler on March 26, 2024 1:56 pmAnswered by the admin

Sorry, we do not know at this time. The only other feed tube is the OPV and this usually does not leak.

Good Morning 1st Line, I posted the below question on February 19 and never heard anything back. Please review and comment. I have a first generation Leleit Bianca from circa 2018-19'---great machine thanks. Issue that I cannot find previously asked in Q&A is a "random" low pressure at group head (builds slowly to only 3-4 MB) at group head when pulling a shot, with low waterflow from grouphead (proven with removal of portafilter after issue occurs), low steam and water from wands left and right. Random means, it occurs on the first shot only immediately after warm-up but only 10 percent of the time (at warm-up, I confirm system always shows great temp and internal pressure). To fix the issue I have pulled 8-14 oz of hot water from wand, ran steam wand for 10 secs and then retried shot. Leaving me to think the cycling the internal pump activating the replacement water might be fixing the issue. Regardless, one or all of those corrective measures appear to "immediately" fix the low pressure symptom....and when they do so the system pressure and temperature all remain indicating the exact same, perfect temp and pressure. Final symptom of the low pressure/low flow is a slightly lighter (hollow) tone in the gear pump pushing the espresso through which immediately returns to perfect normal sound after I fix it. To me, it could be a valve or selonoid issue resulting in a vapor lock or some pressure dysfunction in the system that does not show in the visible guages. Also; the random low pressure can also occur with just a blind in as well.

-

Q Good Morning 1st Line, I posted the below question on February 19 and never heard anything back. ...... Read more answer nowAsked by Randolph Pierson on March 23, 2024 9:27 amAnswered by the admin

Sorry, this one may be complicated. Low grouphead pressure can be a bad pump, a clogged water softener, or MOST LIKELY loss of water in the heat exchange pipes which require filling during the first shot. The loss can come from a leaking OPV, leaking HX pipes, and/or partially opened solenoid valve.

We suggest descaling the grouphead only. Remove water softener before descaling. Otherwise, it may need to be evaluated by a professional as further detailed support is beyond the scope of our free services via Q&A.

I want to make sure I buy the correct part for the seal and group head for Bianca. Are this the correct parts? https://www.1st-line.com/buy/faema-f277/ https://www1st-line.com/buy/petrol-gel-nsf-food-safe-lubricant/ https://www.1st-line.com/buy/lelit-mc930-2/?attribute_pa_terms-conditions-of-sale=no-tech-support-instruction-refund-nor-warranty What other consumables should I buy for machine?

-

Q I want to make sure I buy the correct part for the seal and group head for Bianca. Are this the c...... Read more answer nowAsked by Julian on February 20, 2024 5:31 pmAnswered by the admin

Hello. The recommended grouphead shower/dispersion screen for the Bianca is MC1600069L1 - https://www.1st-line.com/buy/lelit-1600069l1/. The portafilter gasket and food safe lubricant are attached to that page as well.

Good Morning 1st Line, I have a first generation Leleit Bianca from circa 2018-19'---great machine thanks. Issue that I cannot find previously asked in Q&A is a "random" low pressure at group head (builds slowly to only 3-4 MB) at group head when pulling a shot, with low waterflow from grouphead (proven with removal of portafilter after issue occurs), low steam and water from wands left and right. Random means, it occurs on the first shot only immediately after warm-up but only 10 percent of the time (at warm-up, I confirm system always shows great temp and internal pressure). To fix the issue I have pulled 8-14 oz of hot water from wand, ran steam wand for 10 secs and then retried shot. Leaving me to think the cycling the internal pump activating the replacement water might be fixing the issue. Regardless, one or all of those corrective measures appear to "immediately" fix the low pressure symptom....and when they do so the system pressure and temperature all remain indicating the exact same, perfect temp and pressure. Final symptom of the low pressure/low flow is a slightly lighter (hollow) tone in the gear pump pushing the espresso through which immediately returns to perfect normal sound after I fix it. To me, it could be a valve or selonoid issue resulting in a vapor lock or some pressure dysfunction in the system that does not show in the visible guages. Thank you.

-

Q Good Morning 1st Line, I have a first generation Leleit Bianca from circa 2018-19'---great machin...... Read more answer nowAsked by rpier11222 on February 19, 2024 10:01 amA re: Low Pressure at grouphead. 1st Line Eqiup, sorry for the double-tap, I just remembered to share with you on my 19FEB24 Q&A; the random low pressure can also occur with just a blind in as well.

I purchased my Lelit Bianca in March of 2021 from 1st-line. The machine no longer has water (hot or cold) coming out of the valve. The steam and grouphead are all working fine. How can I get hot water flowing through the valve again?

-

Q I purchased my Lelit Bianca in March of 2021 from 1st-line. The machine no longer has water (hot ...... Read more answer nowAsked by Patrick on February 1, 2024 2:04 pmAnswered by the admin This question has been asked below. Please open up the Q&A and search or scroll for the question and the answer we presented.

Hello! Just watched the youtube video on hooking up the Bianca 3 to be hard plumbed. Do y'all sell a filter adapter combo for hooking to external water? Thanks

-

Q Hello! Just watched the youtube video on hooking up the Bianca 3 to be hard plumbed. Do y'all sel...... Read more answer nowAsked by Greg on January 22, 2024 5:55 pmAnswered by the admin

Sorry, we do not and we do not recommend it because if the external water runs out of water, the machine can have significant damage to the pump and motor as well as the heating elements.

Hello - 2 Years of operation without issue. Water has recently started dripping from the hot water spout when fully closed. It's a steady drip and accumulates relatively quickly. I've disassembled the steam wand and did not find any obstructions. Any advice on which parts need replacement?

-

Q Hello - 2 Years of operation without issue. Water has recently started dripping from the hot wate...... Read more answer nowAsked by gvalencia4478 on January 11, 2024 5:45 pmAnswered by the admin

You refer to the hot water spout, but then mention that the steam wand was disassembled. The hot water valve needs to be inspected. Usually, there is debris not allowing the valve to close.

We are happy owners of the Lelit Bianca since a year. We are noticing after each weekly cleaning that the lever is getting stiffer and squeaks a little too. We are wondering if this is normal or if there is any additional maintenance we should perform on the machine?

-

Q We are happy owners of the Lelit Bianca since a year. We are noticing after each weekly cleaning ...... Read more answer nowAsked by Catherine on January 2, 2024 12:25 pmAnswered by the admin

Too much cleaning or overuse of detergent is removing the oils from the lever section of the grouphead.

When I make an espresso, water seems to seep under the machine.

-

Q When I make an espresso, water seems to seep under the machine. answer nowAsked by Yvette on December 22, 2023 12:22 pmAnswered by the admin

Always stop using an espresso machine that is leaking until it is resolved. On a cold machine that s unplugged from the electrical outlet, the top cover would need to be removed to see if there are any leaks. If none are found, a professional needs to get involved to assist. If you purchased through 1st-line, please email us your receipt. Otherwise, please contact the dealer that the machine was purchased from.

Hi I bought my bianca from you guys in 2018. For the last few months I notices a loud motor noise when the machine powers on. And if its been on but sitting, sometimes makes a similar noise when I start making coffee. Noise last for 3-5sec. Any trouble shooting tips? Is there a pump that I could change to prevent sending to you guys?

-

Q Hi I bought my bianca from you guys in 2018. For the last few months I notices a loud motor noise...... Read more answer nowAsked by Julian on December 15, 2023 12:22 pmAnswered by the admin

We suggest testing without the water softener and see if it improves. If it does, it means the water softener needs to be replaced.

If not, then run a descaler through the grouphead and see if it improves.

My Lelit Bianca has a constant hissing noise after warmup. When taking off the top, it sounds to be coming from somewhere by the boiler on the right (steam boiler?). Is there a part I should tighten or replace to fix this? Thank you for the help.

-

Q My Lelit Bianca has a constant hissing noise after warmup. When taking off the top, it sounds to ...... Read more answer nowAsked by Calvin on December 8, 2023 5:28 pmAnswered by the admin

This problem has been identified and previously answered in Q&A. Please open up Q&A and search with Cntrl +F to find leak. We also have a video on our YouTube channel as well. "Bianca leak" can be searched their to find the culprit.

Good morning, my 2 year old Lelit Bianca has started to trip the fuse in the house panel. It turns on for a few seconds, and then trips. I attached it to a different outlet and same thing. How should I proceed?

-

Q Good morning, my 2 year old Lelit Bianca has started to trip the fuse in the house panel. It turn...... Read more answer nowAsked by sugaur on December 8, 2023 12:10 pmA Adding more info. After spending 1 day with a multimeter , it seems like there is no problem with either of the 2 boiler elements. There is good continuity there. One thing which seems off is I am not detecting continuity in one of the solenoid valves ( the one which is smaller and in front). There is continuity in the back solenoid (bigger and one on the back). Is that a potential issue?A More info: hot water/steamer element: 12 Ohms resistance. Infinity when i check between one terminal and ground. Espresso head boiler: 14Ohms.Again infinity between one terminal and ground. I think this rules out these as culprits. On the solenoids, I am getting around 620 Ohms ( one in front and smaller in size) on one and 210 on the other (larger and one on the back). A have eyeballed all wires and don't see any issues. Haven't been able to take a look at the main switch yet, it's difficult to access. Any suggestion on what I should check next?A so i disconnected 2 brown wires which go to the high limit safety switch on top of the coffee boiler ( the sampled inclined tank). The machine does not short when these wires are disconnected. The small switch on the center was NOT raised, so it wasn't tripped. Also, i checked for continuity across this switch and it was continuous. I checked resistance and it shows very low zero). I don't know what all of this means :), could this switch be the issue why my machine is shorting?

Good morning! Our Bianca V3 has started yesterday and again today displaying an error on startup. After displaying the firmware version on the LCC it then alternates between the coffee boiler temperature and the error icon and 05 a few times, and then proceeds to operate completely normally. The extended guide on page 30 says "Temperature probe of the steam boiler is faulty or disconnected" and that the steam boiler would be disabled. It however produces normal steam, and displays normal steam temperature on the LCC when pressing the + (I've never changed from the default; it shows 125C right now). Not sure if I should be concerned or not. Have had the machine since Mid-May 23 and have replaced the in-tank water softener/filter once already. Thanks!

-

Q Good morning! Our Bianca V3 has started yesterday and again today displaying an error on startup....... Read more answer nowAsked by mattandiryna on October 15, 2023 10:12 amAnswered by the admin

Since the machine is fairly new, it seems to be a loose connection. Please unplug machine from the electrical outlet and allow to fully cool down. Remove top cover and body panel per one of our videos. Follow the double red wire from the steam boiler (vertical and wider) to the brain unit. Unplug from the brain unit and replug into the brain unit. Try to test the machine before putting body panel and top cover back on. Do not stick fingers inside as to avoid personal injury.

My v1 Bianca is leaking steam. I did the pinch test from Jim's video (thank you!) and the leak is coming from the steam overpressure valve. The mamometer confirmed it's leaking even when steam is < 1 bar. Additionally the PID looks great and the steam temps on the LCC look great, so I'm strongly speculating the OPV valve itself is just dumping way too low or stuck open. Is there a way to tweak it? If not, what part number is it? Thanks!

-

Q My v1 Bianca is leaking steam. I did the pinch test from Jim's video (thank you!) and the leak is...... Read more answer nowAsked by Ben Blount on October 8, 2023 1:16 amAnswered by the admin

The OPV, steam pressure safety valve and vacuum bleeder valve are three different parts. The OPV is for excessive brew pressure. The Bianca vacuum bleeder valve is for release of vacuum pressure and seals up when there is enough steam built up from the warm up of a cold machine. The Bianca safety valve is for excessive steam pressure when the element, pid sensor, a relay, and/or brain unit allow an overheat scenario.

The vacuum valve and safety valve can leak due to water corrosion. One will either see black, white or green discoloration on the inside portions. They can be descaled after removal from a cold machine and taken apart outside of the machine. However, if the reinstall does not solve the issue, this means water corrosion has usually damaged the inside of these parts beyond a descaling and new ones need to be purchased.

I bought Lelit Bianca v2 couple of years ago and I'm thinking of upgrading. What do I need to get besides the LCC? Is it possible to change the body to white?

-

Q I bought Lelit Bianca v2 couple of years ago and I'm thinking of upgrading. What do I need to get...... Read more answer nowAsked by Tien on October 2, 2023 12:16 pmAnswered by the admin

Sorry, the V2 can not be upgraded to V3 at this time as parts are not yet available. This includes a new LCC and internal parts. A white body is also very costly.

I bought a Lelit Bianca V2 from you in the spring of last year. I am running into the spout leak issue from the steam boiler (I watched your video on this). Could I get an estimate for repairing this issue? In the meantime, I’ll just leave the machine on eco mode.

-

Q I bought a Lelit Bianca V2 from you in the spring of last year. I am running into the spout leak ...... Read more answer nowAsked by Andrew on September 13, 2023 12:15 pmAnswered by the admin We are sorry to read this. In most cases, it is calcium and magnesium build on the valve, and sometimes the PID sensor gets corroded by the same which makes the machine go hotter than it reads, which causes certain parts to prematurely fail. This is why water treatment is so important. Sorry. we are unable to give an estimate because we are uncertain which parts are damaged and the intensity of the cleaning.

My two-year-old (out of warranty) Lelit Bianca stopped working this morning. The power turns on (light ring) but not the LCC. Do I need a new LCC? My model is a V2. It will not heat up. No sign of life other than the power light turning on. Please advise.

-

Q My two-year-old (out of warranty) Lelit Bianca stopped working this morning. The power turns on (...... Read more answer nowAsked by Fernando on September 1, 2023 2:45 pmAnswered by the admin

We are sorry to hear this. Sorry, it can be the power switch, the LCC, the brain unit or a wire. Too many parts to determine which part is defective.

My pump is sounding like it is working very hard when filling the boiler. When it is under pressure, for example when I backflush or even if I pull an espresso, it sounds normal. I replaced the smaller solenoid (9700045) and checked the plunger on the larger one and did not see any debris blocking it. I also checked and replaced the line/tubing from the water resevoir (although that also did not have anything clogging it). What are the next steps for trouble shooting?

-

Q My pump is sounding like it is working very hard when filling the boiler. When it is under pressu...... Read more answer nowAsked by Mike D on July 30, 2023 6:39 pmAnswered by the admin

Sorry to read this. pump noises can be attributable to various external causes. Make sure the reservoir water softener is not clogged by testing with the water softener attached. If plumbed in, reconnect in water tank mode to make sure it is not the plumbing line that does not have the 35psi of water pressure. Too high or too low water pressure can cause a sound.

Next, change the actual pump pressure on the pump. In case and decrease slightly to see if there is an improvement in the sound.

Finally, run a descaler per our instructions on our web site. And, check the inbound side of the pump itself for any debris as we have found one pump with clarified butter on the inbound side of the pump. Please do not ask how it got there as we have no clue.

Good Morning, Lelit Bianca V3, Less than a year old. My flow when pulling is now on full flow no matter what position the flow handle is in. From my understanding I would need to replace the flow valve/needle valve in the group head, correct? I wanted to make sure the part I was going to buy from your website was the correct one. Additionally, what may have been the reason it is no longer working? Home use only, but daily. Normal cleaning. Thank you in advance.

-

Q Good Morning, Lelit Bianca V3, Less than a year old. My flow when pulling is now on full flow no ...... Read more answer nowAsked by onelooneytune on July 11, 2023 11:05 amAnswered by the admin

It can be a broken gicleur or the threads in the holding nut of the flow control is damaged.

I have a v1 Bianca and while I was descaling I got the Error 3. It sounds like the pump is really struggling. I checked the tube from the tank to the machine and it looks okay. Any suggestions? I have the cover off and don't see anything obviously wrong but I am worried that I haven't had a good flush of the descaler.

-

Q I have a v1 Bianca and while I was descaling I got the Error 3. It sounds like the pump is really...... Read more answer nowAsked by Mike D on July 2, 2023 5:06 pmAnswered by the admin

Please review our error codes page.

Hello, I am currently in the process of moving overseas for military service in Japan. I will be bringing my lelit Bianca v3 with me, however because I’m moving to Tokyo, they will have 100v/50hz power. Is there any chance you know what parts I would need to swap over ? I’m assuming it would just be the motor and the plug end. Any assistance would be appreciated … as I’d love to purchase the parts I need to convert over and continue using my machine

-

Q Hello, I am currently in the process of moving overseas for military service in Japan. I will be ...... Read more answer nowAsked by Damian on June 29, 2023 11:08 amAnswered by the admin

Thank you for your service. Sorry, we would not have any of the parts for a conversion. Just think that we would need the parts for every other country's differences. This is a question that needs to be answered by Lelit, but even more important, the importer in Japan. Again, we are sorry we could not assist.

Hey I got this Bianca from you guys in Dec 2020. We are having an issue with the steam boiler error. In the beginning it was only every now and then, and turning it off and back on again would fix it. It's on a wifi switch, so now that it's gotten worse I'm waking up to find error 3, I'll turn it off and back on, and the pump runs and runs. Then if I immediately turn it off after 5-10 seconds, let it wait a couple more seconds, then turn it back on, a solenoid or something clicks, the pump sound changes and stays on only a moment, and it starts up normally. What could be the issue?

-

Q Hey I got this Bianca from you guys in Dec 2020. We are having an issue with the steam boiler err...... Read more answer nowAsked by Ryley on May 18, 2023 2:06 pmAnswered by the admin

Sorry to hear this. Here is a list of error codes for the Bianca.

I have owned my Bianca for 2.5 years, with proper regular maintenance. Recently, water began dripping from the over-pressure valve outlet below the group head. it drips slowly, but constantly when the machine is on, eventually filling the drip tray. It has not previously done this. Water does not run out of the OPV when brewing, so i do not believe it is caused by the OPV being too loose. What could be causing this?

-

Q I have owned my Bianca for 2.5 years, with proper regular maintenance. Recently, water began drip...... Read more answer nowAsked by Dave on May 8, 2023 4:41 pmAnswered by the admin

Cause: corrosion from water. This question was asked and answered at least twice below. please search for the question and how to resolve.

I watched the video you posted about spout leakage for the Lelit Bianca. It looks like I need to replace the Safety Valve. I have a Bianca V2, which part should I purchase? It seems the part might have changed between the V2 and V3? Also I need to replace the tubing as well, do you sell that?

-

Q I watched the video you posted about spout leakage for the Lelit Bianca. It looks like I need to ...... Read more answer nowAsked by Joshua on April 24, 2023 11:57 amAnswered by the admin

Please search for part numbers and/or descriptions on our web site. Sorry, we try our best to refrain from answering here because parts do get discontinued and then the links become invalid and hard to find to correct. As far as we know, the safety valve has not changed.

Hello, i have purchased a Lelit Bianca V3 from you. I notice that the grouphead pressure exceeds the boiler pressure by ~1.5. i.e. boiler pressure is set at 9bar and grouphead is showing 10.5 at beginning of the extraction. What do you advise i should do to troubleshoot?

-

Q Hello, i have purchased a Lelit Bianca V3 from you. I notice that the grouphead pressure exceeds ...... Read more answer nowAsked by Jonathan on March 6, 2023 2:23 pmAnswered by the admin

Grouphead pressure is not really related to boiler pressure. It is related, BUT NOT directly proportionally to the pump pressure.

The pressure gauge on the lower front panel is pump pressure reading.

The pressure gauge on the grouphead is a BREW pressure gauge. This gauge shows the result of the resistance that equates from the fineness of the grind, the amount of coffee in the basket AND the tamping pressure. This pressure will likely read differently than the pump pressure gauge as

a) it is measuring different parameters,

b) it is in a different location,

c) it is known to be different even when using a blind.

Can this be used as a commercial machine, can it be used in a coffee shop!?

-

Q Can this be used as a commercial machine, can it be used in a coffee shop!? answer nowAsked by Hugo on February 15, 2023 4:43 pmAnswered by the admin

We do have clients who have used the Lelit Bianca in a coffee shop, in a mobile coffee truck, and/or mobile catering. In December of 2019, we performed a fund raiser event at a local charity and the Bianca made well over 250 8 ounce cups of cappuccino in a 4 hour period.

Please be aware that some towns, cities, counties, and/or states require NSF approval, and then there are the same that do not require any approvals as it is up to the local health inspectors.

It is best to find out from your local health inspector on the requirements, including the grinder.

What do you recommend as a temperature for the steam boiler? Do most people leave it stock? Any downsides to turning it up?

-

Q What do you recommend as a temperature for the steam boiler? Do most people leave it stock? Any d...... Read more answer nowAsked by Ben on February 2, 2023 12:01 pmAnswered by the admin

Leave stock and raise it when entertaining or using in a commercial environment.

I bought a Lelit Bianca from you ~ 2 years ago. Recently I've started to notice some inconsistent steam pressures coming out of the stream wand. In addition, sometimes there are too much water coming out of that wand together with the steam. I'm wondering if this has something to do with scale buildups. From where I live (north NJ), the water is pretty hard. I'm using the BWT BestMax Premium Filter at 0 settings, but I don't know how much that would help softening the water. Either way, I'm wondering if there is some descaling work that I can do on my own, at least to figure out whether scale is the issue or not. Please let me know!

-

Q I bought a Lelit Bianca from you ~ 2 years ago. Recently I've started to notice some inconsistent...... Read more answer nowAsked by Hao on January 25, 2023 5:52 pmAnswered by the admin

It sounds like the refill probe is scaled up. It needs to be removed and cleaned with a wire brush. The machine can be dropped off for service if you like.

I want to open the group head for cleaning. Any tips on how to remove the sprayer nozzle MC930-4? It has a wide grove that fits a screw driver. A narrow screw driver doesn't work easily. I'm concerned the nozzle can be damaged since it's soft bronze/brass if I put a lot of force on it.

-

Q I want to open the group head for cleaning. Any tips on how to remove the sprayer nozzle MC930-4?...... Read more answer nowAsked by Toby on January 4, 2023 1:04 pmAnswered by the admin

Just use backflush detergent to clean. Please do not run the risk of taking apart the grouphead if you are usnure what you are doing.

We use filter water with the softener. We change softener every 6 months. And every 2 months we descale with urnex.

-

Q We use filter water with the softener. We change softener every 6 months. And every 2 months we d...... Read more answer nowAsked by Jamie on January 3, 2023 11:54 amAnswered by the admin

We suggest not descaling unless there is a problem with the machine.

Our lelit Bianca espresso machine all of a sudden won’t stop creating steam in the overflow value - I tried to descale it and cycled the machine off but still having issues, do you have any suggestions on what we should do?

-

Q Our lelit Bianca espresso machine all of a sudden won’t stop creating steam in the overflow value...... Read more answer nowAsked by Jamie on December 29, 2022 11:55 amAnswered by the admin What specific water are you using and what water treatments have been implemeneted since first use?

I purchased a Lelit Bianca Pro line PL162T from you less than a year ago and have had problems with pressure. It has been very difficult to get reasonable pressure, even with very fine grinds. Now, I am getting no pressure at all. Either the pressure gauge is not functioning and/or the pump is not working well.

-

Q I purchased a Lelit Bianca Pro line PL162T from you less than a year ago and have had problems wi...... Read more answer nowAsked by Christopher Anzalone on December 27, 2022 10:30 pmAnswered by the admin Well, there are three pressures. The steam pressure on the steam pressure gauge on the front panel. Second, there is pump pressure on the pump pressure gauge on the front panel. Third, there is brew pressure gauge which is located on the grouphead. Hence, we are unsure if you are referring to the pump pressure or the brew pressure. As for no pressure at all, which gauge? Lastly, just post the specific issue in a NEW question. Second, do not offer the solution. The reason is that your water softener may be clogged and my not allow pump pressure nor brew pressure to increase. Lastly, when is the last time you recharged the water softener and how many months ago did you replace it? We are unsure what you mean reasonable pressure. Do you mean pressure too high or too low? And, which gauge?

I am located in San Diego, we have some exceptionally hard water (2021 report 14.9 gr/gal), ph ~ 7.5, confirmed out of my tap with meters. I am not planning on plumbing the unit. I am limited to using the tank. Is there an under-the-sink filtration / softener system that can be plumbed to a tap? Can the BWT system be plumbed to a tap?

-

Q I am located in San Diego, we have some exceptionally hard water (2021 report 14.9 gr/gal), ph ~ ...... Read more answer nowAsked by Terrence on November 21, 2022 12:31 pmAnswered by the admin

We strongly suggest diluting the tap water without 50-80% of distilled water and continue to use the Lelit water softener (recharging every week and repalcing every 6 months). The BWT may counteract the Lelit softener. Hence, if using the BWT to a separate dispensing faucet, then use the BWT only.

The steam arm has become stiff and creaky. The arm is stiff even when the machine is hot. I have not been using the water filter because my municipal water was tested and it is pretty soft. I descale the machine about once a year. How can I fix the stiff steam arm?

-

Q The steam arm has become stiff and creaky. The arm is stiff even when the machine is hot. I have ...... Read more answer nowAsked by Steve on November 4, 2022 4:07 pmAnswered by the admin

The ball joint may need some high temp food grade grease, such as Petrol-Gel or equivalent.

I purchased my Lelit Bianca from you about 2.5 years ago. It’s generally been fantastic, but lately it has started to leak from the e61 grouphead exhaust port when brewing. Previously it would discharge water after brewing finished, which seems like the normal operation. Now, however, I’m getting a small but continuous drip while the pump is operating. For what it’s worth, the machine seems to be maintaining as much pressure as it ever had. So a/ is this a problem, and b/ if so, how should I fix it?

-

Q I purchased my Lelit Bianca from you about 2.5 years ago. It’s generally been fantastic, but late...... Read more answer nowAsked by bbbbbbbb on October 25, 2022 7:18 amAnswered by the admin

Please backflush as particles may be holding the valve open. Otherwise, it can be too fine a grind that is creating too much back pressure.

My under warranty machine will now not work on any 15amp circuit in my house. It will trip any NEW 20amp GFI circuit. It will only work on a 20amp non-gfi circuit. Please advise.

-

Q My under warranty machine will now not work on any 15amp circuit in my house. It will trip any NE...... Read more answer nowAsked by brookef on October 12, 2022 1:49 pmAnswered by the admin

This means you have a short inside the machine somewhere. The short can be a heating element inside either boiler, the solenoid valve, or wiring that burned up and is touching metal. The machine, unplugged from the wall outlet, would need to be visually inspected inside with both top cover and body panel removed. The wires would need to be removed from each heating element, and the element tested for an ohm reading which can range from 8-20 ohms.

My Bianca, purchased at 1stLine 12/2020, trips outlet breaker seconds after the machine is turned on right after the temp is noted. This is NOT a GFCI issue as it trips ANY outlet, GFCI or otherwise, it has been tested on. I appears the load on the heating elements is causing the fail. I have removed the cover and back of machine. Machine is dry (dusty even...) inside. Electrical and plumbed connections are tight. Please advise as to how to proceed with repair/warranty. I am located in San Francisco Bay area. Local referral would be appreciated.

-

Q My Bianca, purchased at 1stLine 12/2020, trips outlet breaker seconds after the machine is turned...... Read more answer nowAsked by brooke on September 21, 2022 9:54 pmAnswered by the admin

A multi-meter is needed to check the ohms or each heating element. All parts and wires need to be inspected for damage or a short. If all the GFI outlets are older than 3-4 years, it could be bad GFIC outlets.

Today my steam valve knob came unthreaded from the the machine and would not turn on the steam on. It seems that the set screw that holds the knob onto the cable threads may have snapped. I haven’t had any luck finding the part number for that piece. Any help would be appreciated.

-

Q Today my steam valve knob came unthreaded from the the machine and would not turn on the steam on...... Read more answer nowAsked by Kevin Andrews on September 17, 2022 10:14 amAnswered by the admin

Sorry for the delay. We have learned a few machines did not have "any or very little glue/sealant" to hold the threaded fitting to the inside of the wood knob. If you have a permanent glue to place on the inside of the wood, this would work. The c-clip does need to be removed from the stem before re-insertion.

My Bianca purchased at 1stLine 12/2020 is now tripping GFCI 110 outlets. Worked fine before leaving for 1 week vacation. Upon return, I turned on machine and it immediately tripped the circuit after lighting the LCC. Checked several outlets, same result. Please advise.

-

Q My Bianca purchased at 1stLine 12/2020 is now tripping GFCI 110 outlets. Worked fine before leavi...... Read more answer nowAsked by brookef on September 13, 2022 5:29 pmAnswered by the admin

Please review our white paper on GFIC.

Hi all, question about V2 machine. The pressure profile bar stopped working/showing the actual pressure at the time of pulling a shot. Why would this be? What is the reason(s) this gauge stopped working all of the sudden today after turning the machine on?

-

Q Hi all, question about V2 machine. The pressure profile bar stopped working/showing the actual pr...... Read more answer nowAsked by Al Sandler on September 3, 2022 10:13 amAnswered by the admin

It needs resistance in the portafilter to show resistance pressure, or the gauge area tube area is corroded with oxidation of limescale.

I am looking to buy a single spout portafilter for my Lelit Bianca and you have two on your website that are the Lelit brand and I’m not sure which one to get. One is 79.99 and the other is 89.99. Is there any difference between them?

-

Q I am looking to buy a single spout portafilter for my Lelit Bianca and you have two on your websi...... Read more answer nowAsked by Stefan on July 28, 2022 12:33 pmAnswered by the admin

We recommend the higher price one as it is the more modern design like the Bianca.

Hello, my Bianca that I bought from you 2 years ago has recently started dripping into the tray from the little fitting after it's warmed up. It's a drip and also see some condensation from maybe steam. I have it plumbed in running through a filter made for coffee/espresso machines by Homeland HCWS. I drain the steam boiler regularly and my water is clear. How can I figure out what this could be? Thank you for your time, I've enjoyed this machine very much. It's been trouble free since you replaced my gliceur when I received it.

-

Q Hello, my Bianca that I bought from you 2 years ago has recently started dripping into the tray f...... Read more answer nowAsked by Orlando on July 25, 2022 12:28 pmAnswered by the admin

Sorry to hear about this. The top cover would need to be removed. Power on the machine and allow to heat up. WARNING! Do not stick your fingers inside as it will get very hot. You will see two hoses exiting the steam boiler - one on the horizontal safety valve and one on the vertical vacuum breaker bleeder valve. Check to see which hose has a steam vapor going through. Be careful as you can squeeze each one for 2 seconds to see if there is a visible or verbal puff. If yes, this is usually corrosion from hard or too pure water. After the machine is completely cooled down and unplugged from the electrical outlet, both hoses can be removed by tugging on them. They may break. The affected part can be removed and soaked in descaler solution overnight. Then rinsed and reinserted using 2-3 rounds plumbers tape on the threads. Test. If problem continues, the part would need to be replaced as well as the water choise needs to be re-evaluated. We are not water treatment experts, so we are unsure about the system you have.

Have been very happy with our Bianca for nearly three years now. This morning I pulled two espresso’s and on the third one with no warning no water is being released into the grouphead when I pull the lever. Both boilers are heating up and the steamer seems to be working with a little less pressure. Can you help me, please

-

Q Have been very happy with our Bianca for nearly three years now. This morning I pulled two espres...... Read more answer nowAsked by LeeH000001 on July 15, 2022 8:20 pmAnswered by the admin

Please check without coffee. Your water softener may also be clogged.

A No water coming out of Grouphead, so no coffee in Porto filter installed during pull. Water softener has been disconnected. This response is for the Q & A page. I have been communicating through email and have reached an impasse with tech support. No one is communicating with me. I have sent two requests; no response. At this point I’m just replacing parts, guessing at what the problem could be. I have thoroughly cleaned the Grouphead, checked all of the solenoids for obstructions, checked the heating elements, replaced Y joints which exploded previously, replaced the Grouphead Lever microswitch, replaced the steam boiler safety valve, replaced the Vacuum breaker valve (which corrected the leaking problem from the boiler. Grabbing at straws at this point, but could it be the probes which could be causing a bad reading?

I really have two questions: the first is for the Lelit detergent that the manual notes (PLA9201). I cannot find that on first line website. I’m wondering if this is a special kind of detergent, or if I could just as easily use 3.5 g of Urnex detergent for coffee machines, then following the back flush procedures in the manual. My other question is regarding the Lelit resin filter. I want to make sure that I understood the process from your YouTube video. That is that I can put the 70 L filter in a glass of salt water for 20 minutes, then flush it out with fresh water for five minutes and continue to use this for one year before replacing. Thought I’d ask before doing something I would regret!

-

Q I really have two questions: the first is for the Lelit detergent that the manual notes (PLA9201)...... Read more answer nowAsked by Mitch on July 7, 2022 12:58 pmAnswered by the admin

Urnex Cafiza can be used for backflushing, BUT NOT used for descaling as some customers confuse.

Water softening recharge instructions can be reviewed.

I bought a Lelit Bianca from you in mid-2020. I am wondering if you can advise on what sort of service should be done beyond backflushing, and who you recommend? I appreciate these machines are quite specialized and I imagine that the technicians doing such work are not ubiquitous. I am hoping you can give me an idea of when I should have my Bianca serviced by a professional, and if so, how I might go about setting that up, when necessary. The only issue we have had thus far is that the mechanism by which the machine notifies us that the reservoir is out of water is non-functional, so we have to watch the reservoir level a little more closely. We haven't noticed any issues with the machine as a result, nor any other issues. Thanks!

-

Q I bought a Lelit Bianca from you in mid-2020. I am wondering if you can advise on what sort of se...... Read more answer nowAsked by Erik on July 5, 2022 3:33 pmAnswered by the admin

We do not suggest descaling unless there is a water issue causing machines issues.

As for the low water notification, please make sure the black audio cable under the machine is taken out on both ends and re-inserted.

I'm currently on the wait list for the V3 Bianca. I'm currently researching puck screens and wanted to know if the size should be 58.5 mm. I'm looking at the normcore. Do you have a better suggestion?

-

Q I'm currently on the wait list for the V3 Bianca. I'm currently researching puck screens and want...... Read more answer nowAsked by Mark on June 29, 2022 12:14 pmAnswered by the admin

Sorry, at this time, we can not confirm a fitment of the "normcore" nor any other suggestions of alternatives.

Need to automate a bit my Bianca with Wi-Fi outlet or something. Please advise. Regards.

-

Q Need to automate a bit my Bianca with Wi-Fi outlet or something. Please advise. Regards. answer nowAsked by Tim on June 15, 2022 2:31 pmAnswered by the admin

Wemo.

Follow-up answer stemming from my 7 JUN Question: Good afternoon 1st line Equipment, In response to your suggestion on troubleshooting techniques for my bubbling Lelit Bianca over pressure bypass valve the following applies: I was able to crimp the clear hose and stop the bubbling. Hose Identifying Location: Viewing from the top, facing the espresso machine straight on working with the larger boiler on the right, I crimped the horizontal plastic tube that comes off the horizontal brass fitting that is connected to the series of nuts that go in the vertical near center of the boiler. Meaning, the hose that I crimped and stopped the air from bubbling out the bypass on the front of the machine was the short clear hose that comes off the top of the right boiler from the center towards the upper left-hand quadrant of the top of the boiler (hose lays horizontally on boiler). After the boiler the tube I crimped immediately joins a plastic “y“ fitting. Please let me know at your earliest convenience if this is a repair that I am able to buy the parts from you and facilitate the repair myself. I do have pictures and video available. I do not see any sediment or minerals in the clear tubing, all water looks clear, and as I said earlier this espresso machine has been on the BWT filtering system since purchase. Thank you for your assistance, Randy

-

Q Follow-up answer stemming from my 7 JUN Question: Good afternoon 1st line Equipment, In response ...... Read more answer nowAsked by rpier11222 on June 9, 2022 4:25 pmAnswered by the admin

This seems to be the safety valve.

Jim, good evening. I have the Lelit Bianca that I bought from you approximately three years ago. I have had great enjoyment from it and good reliability. About a week ago as it would warm up from a standby condition it would start bubbling out of the front of the face plate from the bypass just behind and underneath the Porta filter back flush port. I have I have read all the questions and answers for the Lelit Bianca and it seems like most of the time issues can be related to the quality of water I want to say right upfront since I purchased this machine from you it has been on a BWT water filter system the entire time. What is occurring is when it comes up in temperature from a standby mode pretty quickly it starts bubbling with a very light airflow, slighter than a whisper and does that continuously as it comes up and maintains temperature. I have the steam boiler at 268° and the espresso boiler at 203°. It doesn’t matter how high I run the steam boiler or how low I run it I still get this bubbling about one bubble every second or two out of the bypass. When I adjust the temperature to the steam boiler I get a decrease in pressure when I reduce it and an increase in pressure when I increase it, nothing feels unusual or leads me to think I have an overtemperature occurrence. I have pictures and video if that’s helpful. My uneducated opinion is I have a minor valve failure, where I am not getting a good seal resulting in a very minute amount of air with moisture escaping from the boiler. Thank you for your assistance and recommendations on how I can fix this.

-

Q Jim, good evening. I have the Lelit Bianca that I bought from you approximately three years ago. ...... Read more answer nowAsked by rpier11222 on June 7, 2022 10:30 pmAnswered by the admin

We have found, in cases of limescale or oxidation, either the bleeder (vacuum breaker) valve or the safety valve or both would not create a good seal. One way to test this is to remove the top cover and pinch one hose at a time (both on steam boiler) to determine which part is leaking. When pinched, the bubbling should stop. WARNING!!! BE VERY CAREFUL as one can get burned and we assume no responsibilities for any injuries or damages from performing this diagnostic task. You may also see the bubbling without pinching.

We bought our Bianca from 1st Line and recently the brew lever is sticking and we aren’t sure whether it needs to be oiled, replaced etc?

-

Q We bought our Bianca from 1st Line and recently the brew lever is sticking and we aren’t sure whe...... Read more answer nowAsked by Brad on May 16, 2022 2:13 pmAnswered by the admin

This is a result of backflushing with too much detergent or purified water - both result in the lubrication being removed. We suggest high temp food grade grease inserted in the cams at the inside end of the stem of the grouphead lever. Otherwise, over time, coffee oils may re-grease this area.

We bought our Bianca from 1st Line and recently the brew lever is sticking and we aren’t sure whether it needs to be oiled, replaced etc?

-