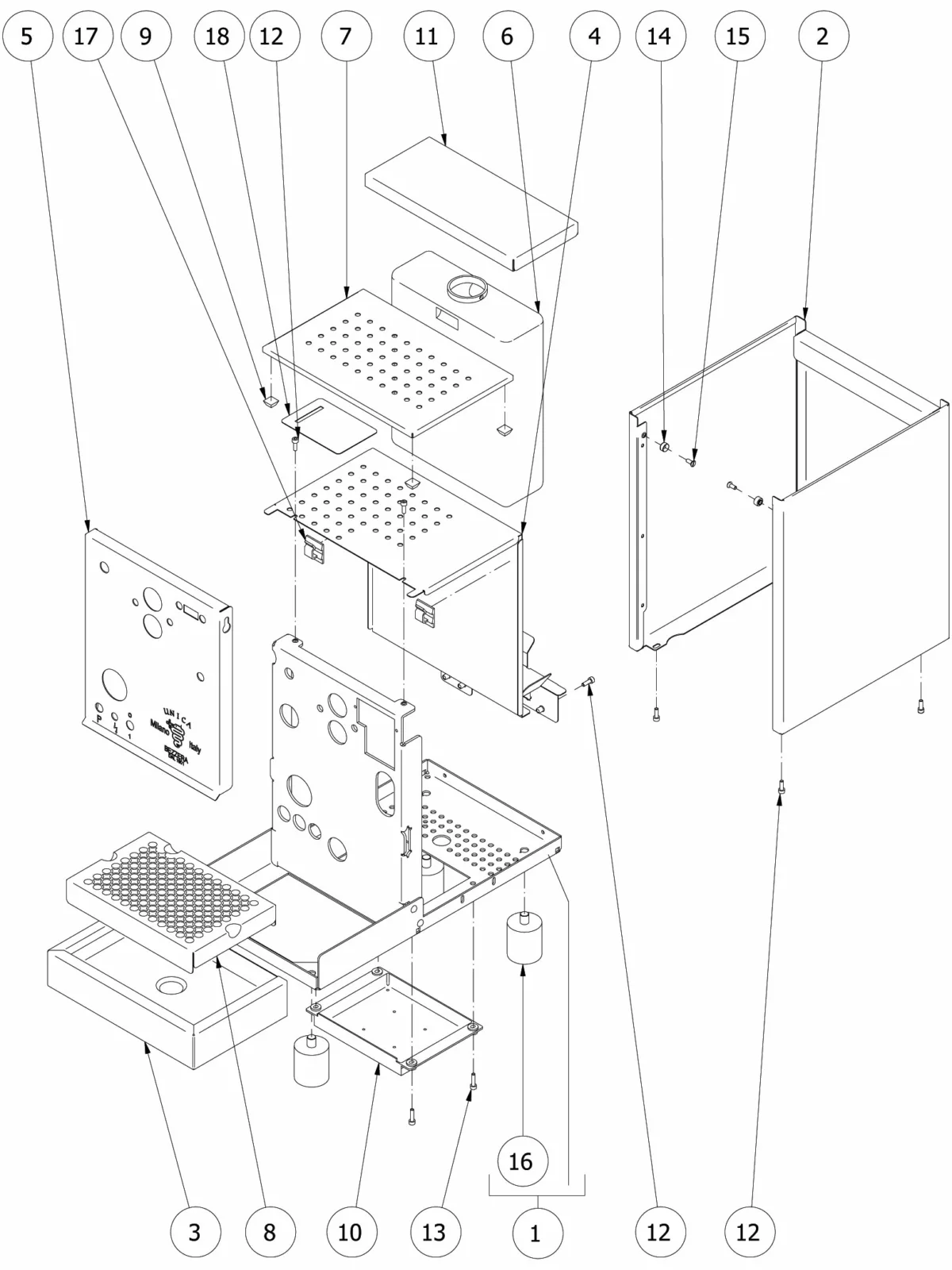

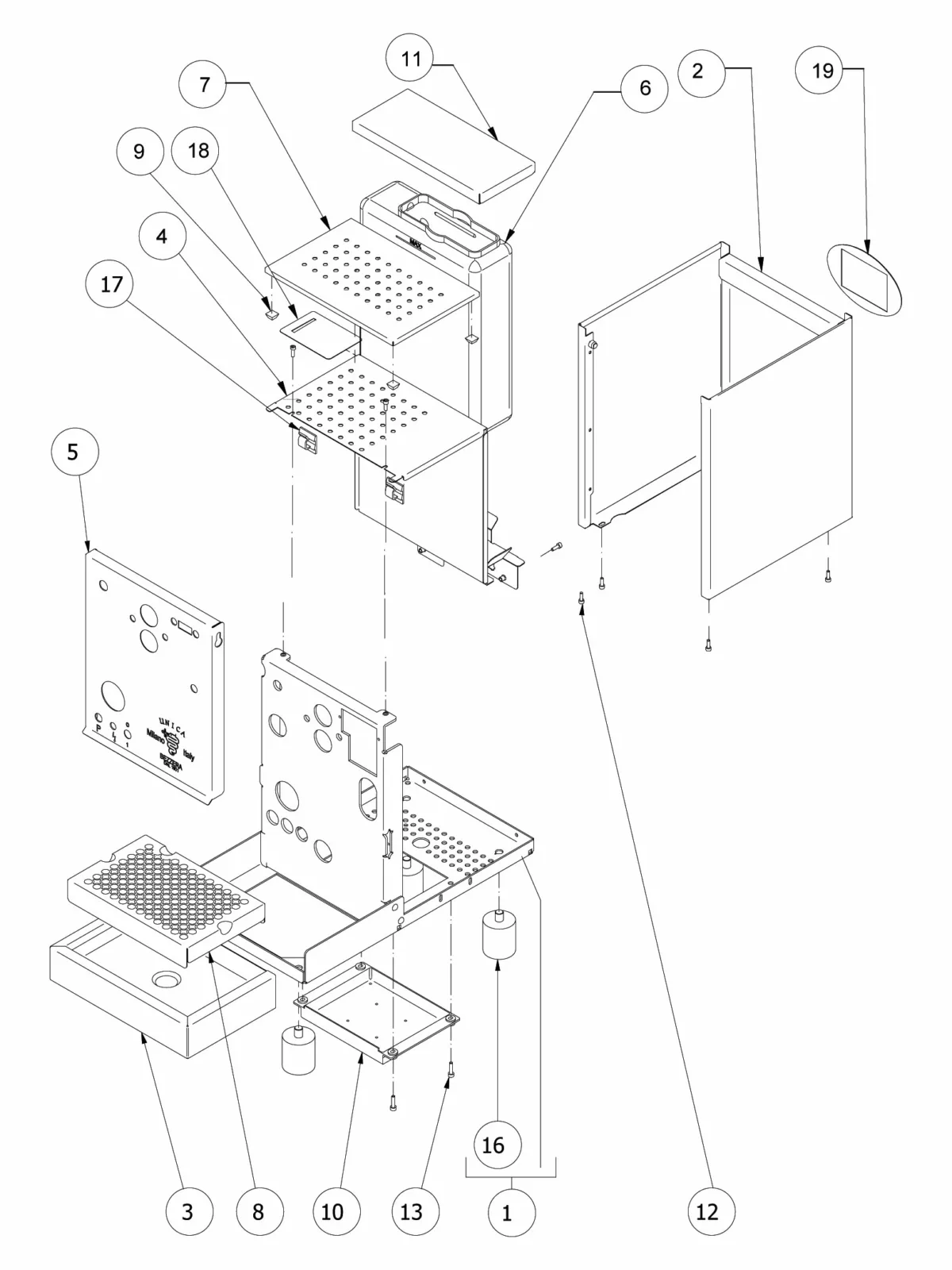

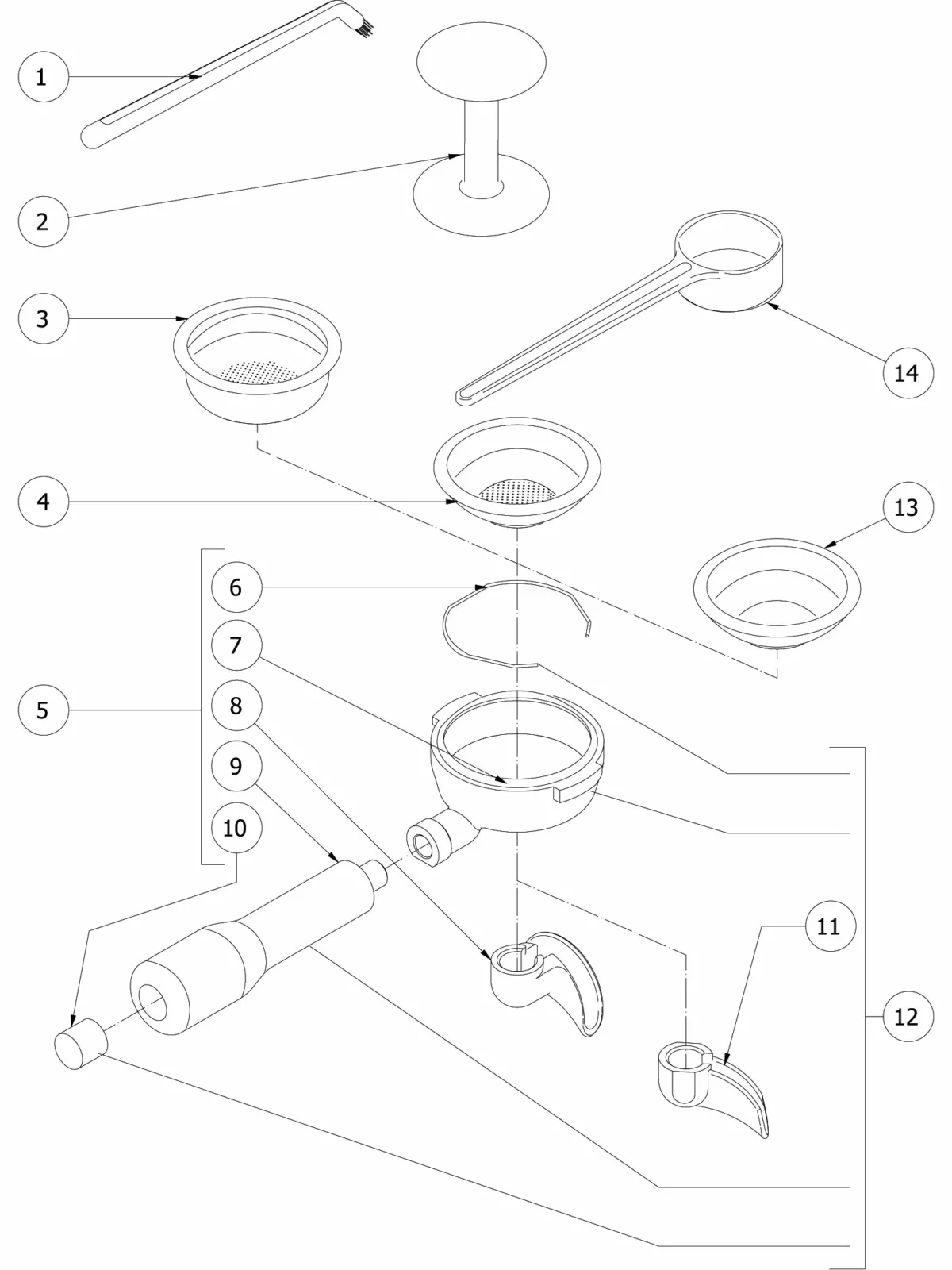

VBM Domobar Junior HX Espresso Machine

Enjoy a great latte or creamy cappuccino from a VBM Domobar Junior espresso machine. VBM calls it ‘Junior’ because of its smaller footprint for those customers who do not have the room nor space for the larger Super espresso machines, such as a model with a rotary vane pump or the other with a vibration pump.

A little history… based on the great success of the VBM Domobar Super Heat Exchanger (a.k.a. HX) espresso machines in the USA since 2006, VBM has designed the VBM Domobar Junior HX in 2010 for those customers who need a smaller footprint. The VBM Domobar Junior HX offers the same

- ability to extract espresso and steam milk at the same time, and

- ability to change the pressure in the boiler which is a direct proportional relationship to the temperature.

Please note:

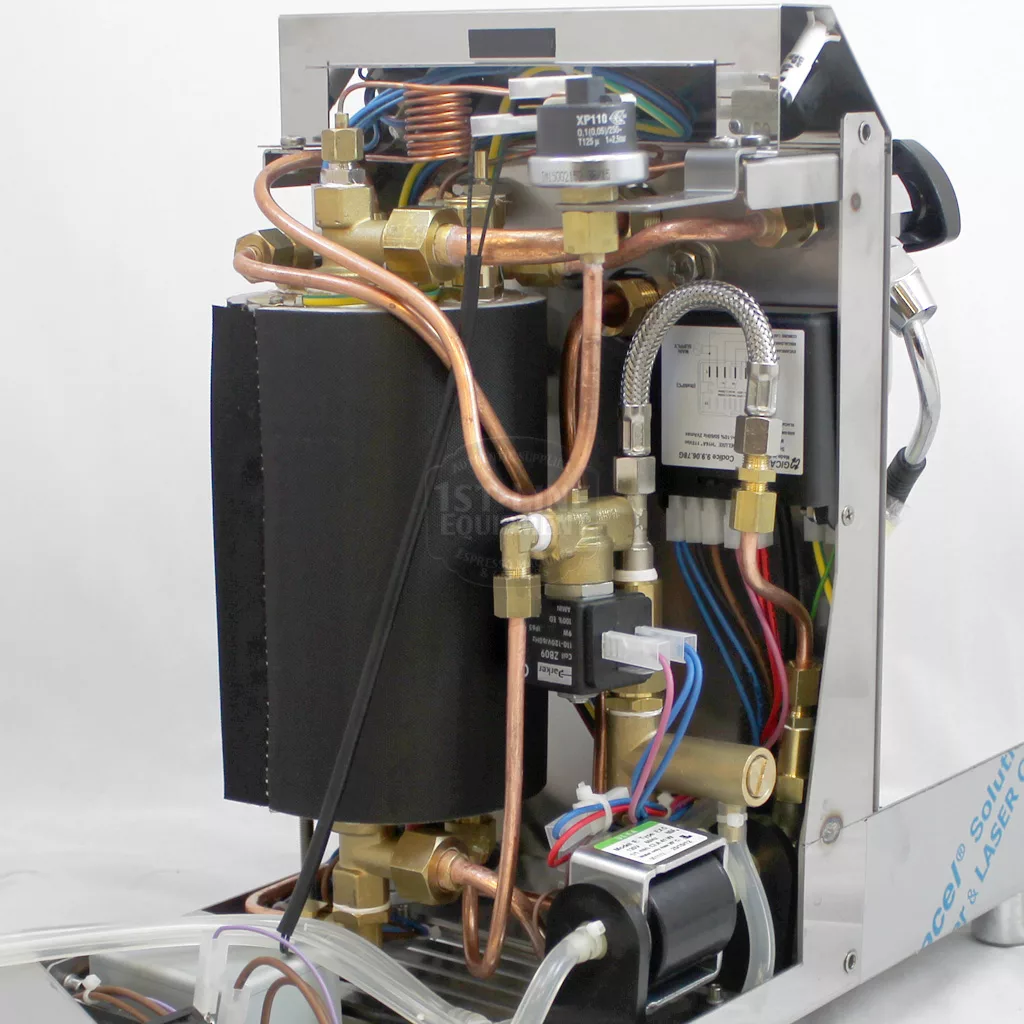

for VBM to offer a lower price when you compare to the Super machines, the following features are different mostly due to the smaller space available inside the machine

- The VBM Domobar Junior’s footprint is smaller for those customers who have less space, but smaller size means less metal (lower cost).

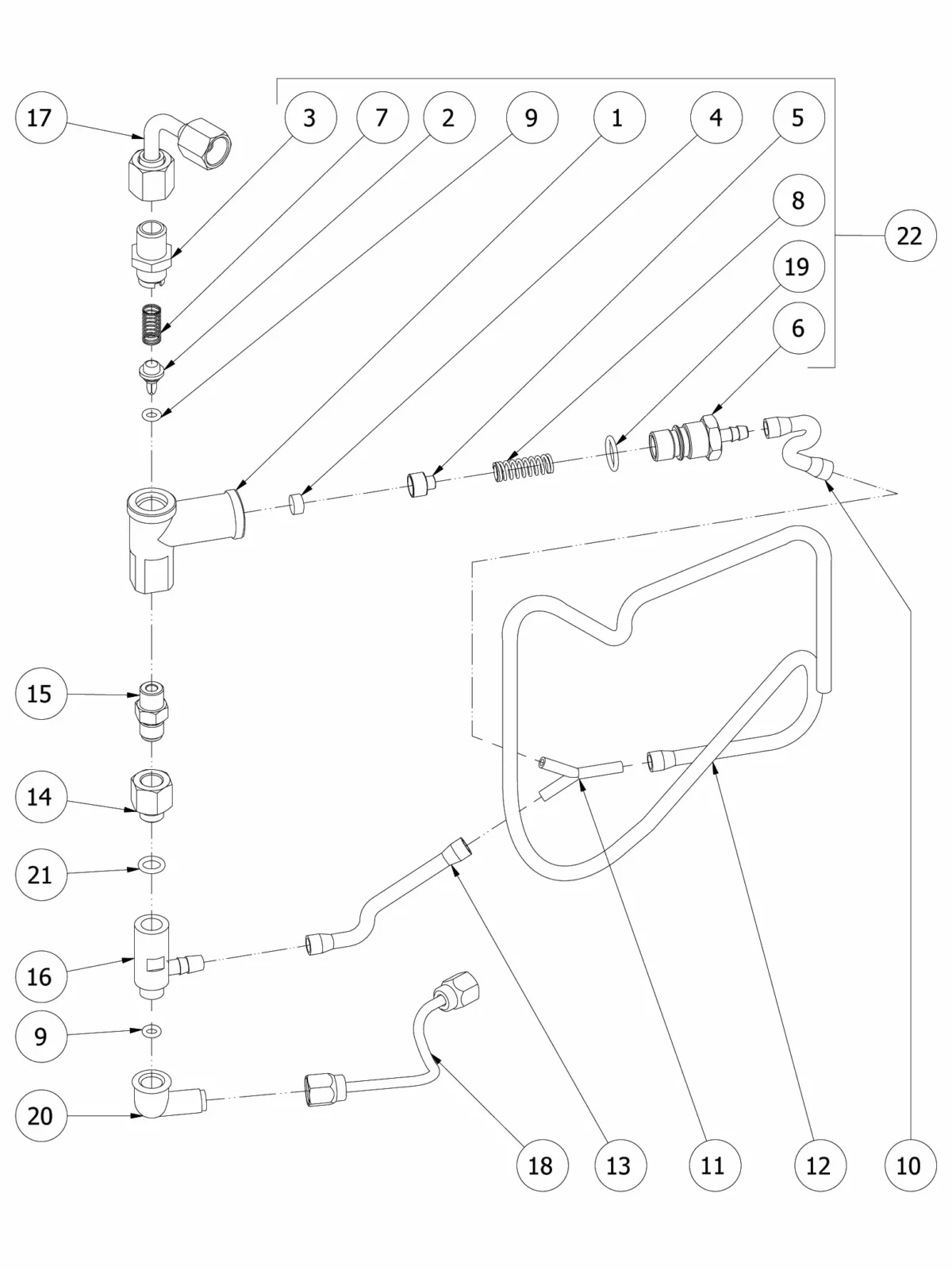

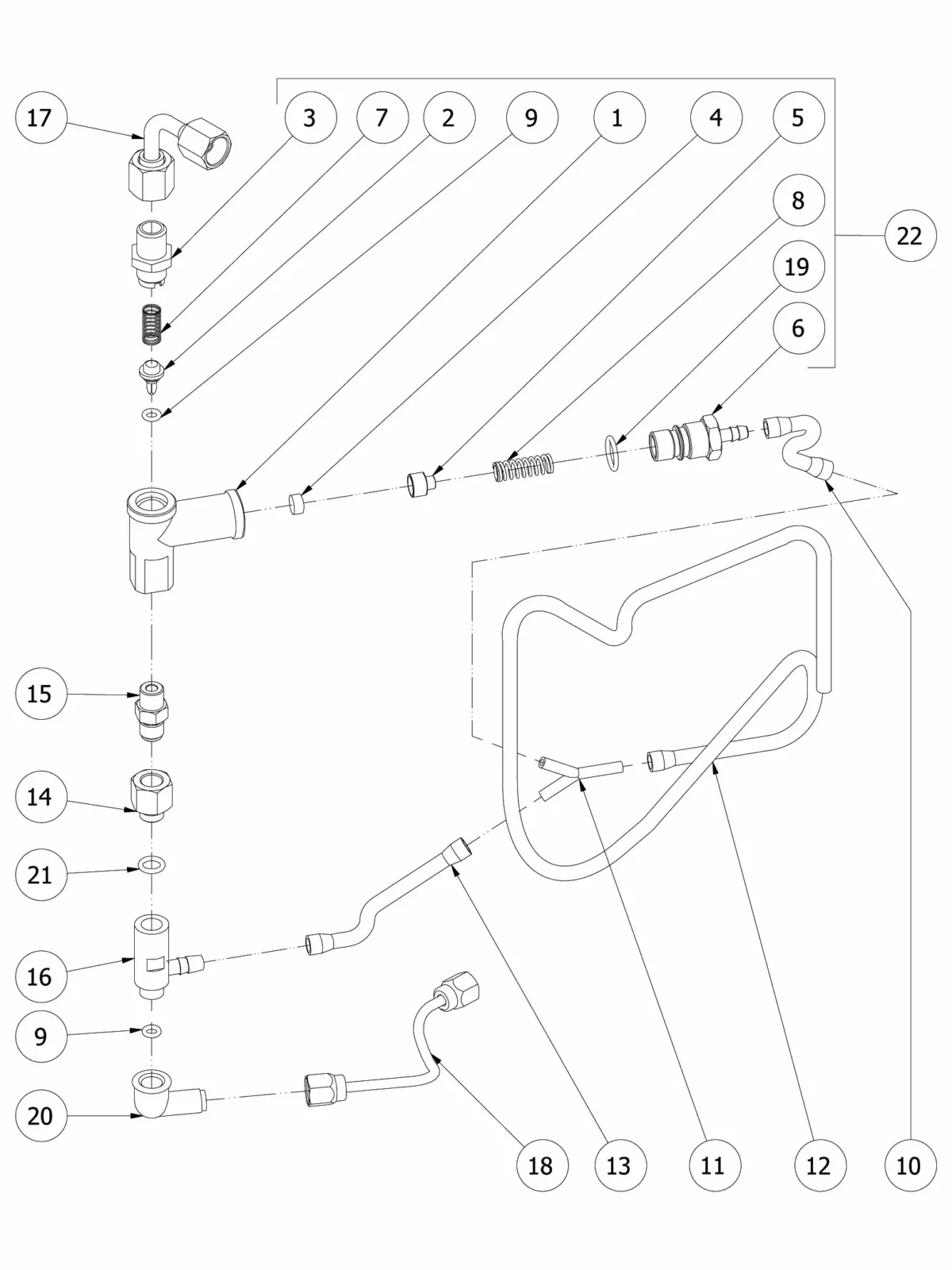

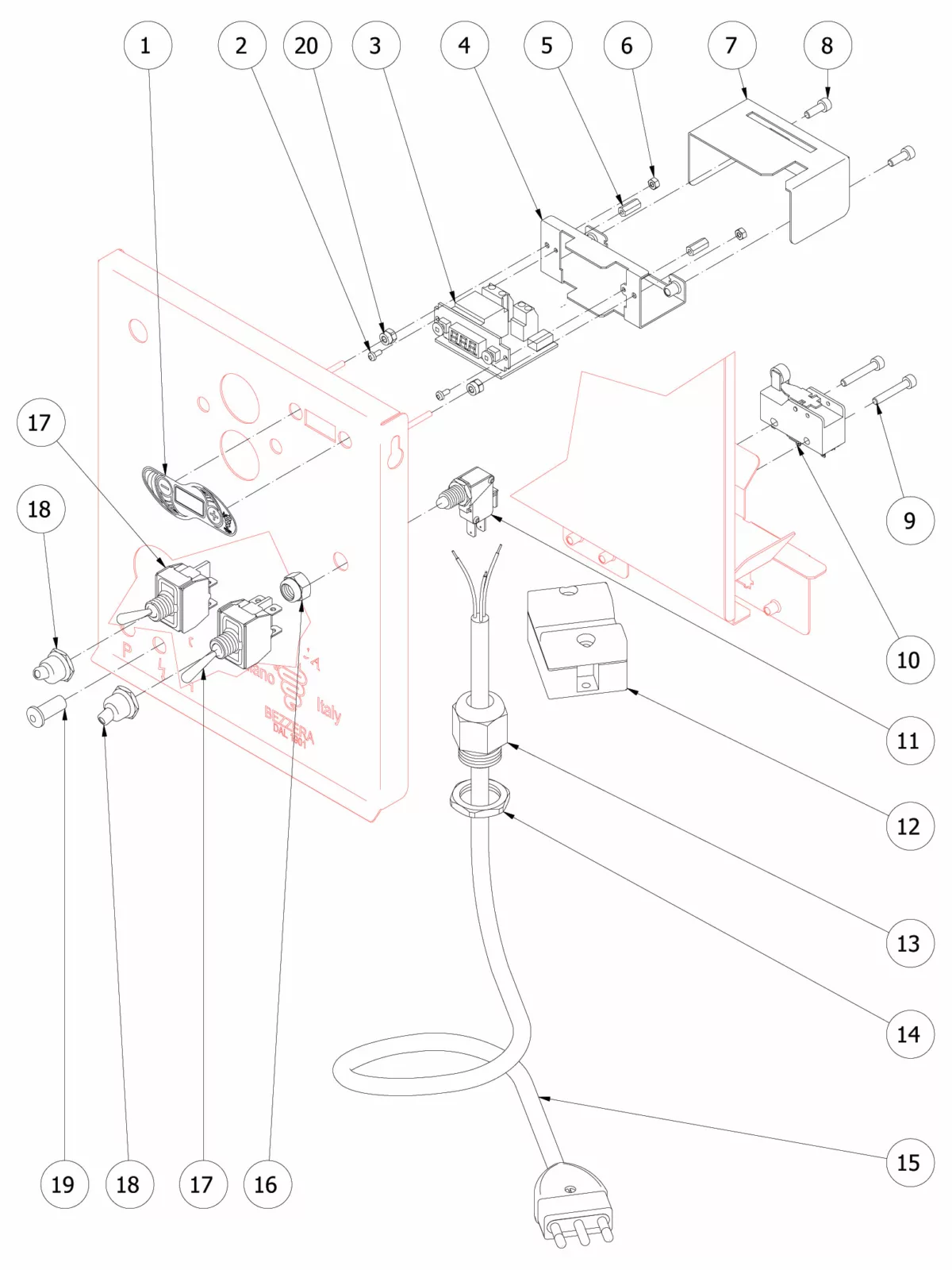

- A smaller pressurestat controls the boiler. This part requires manual descaling.

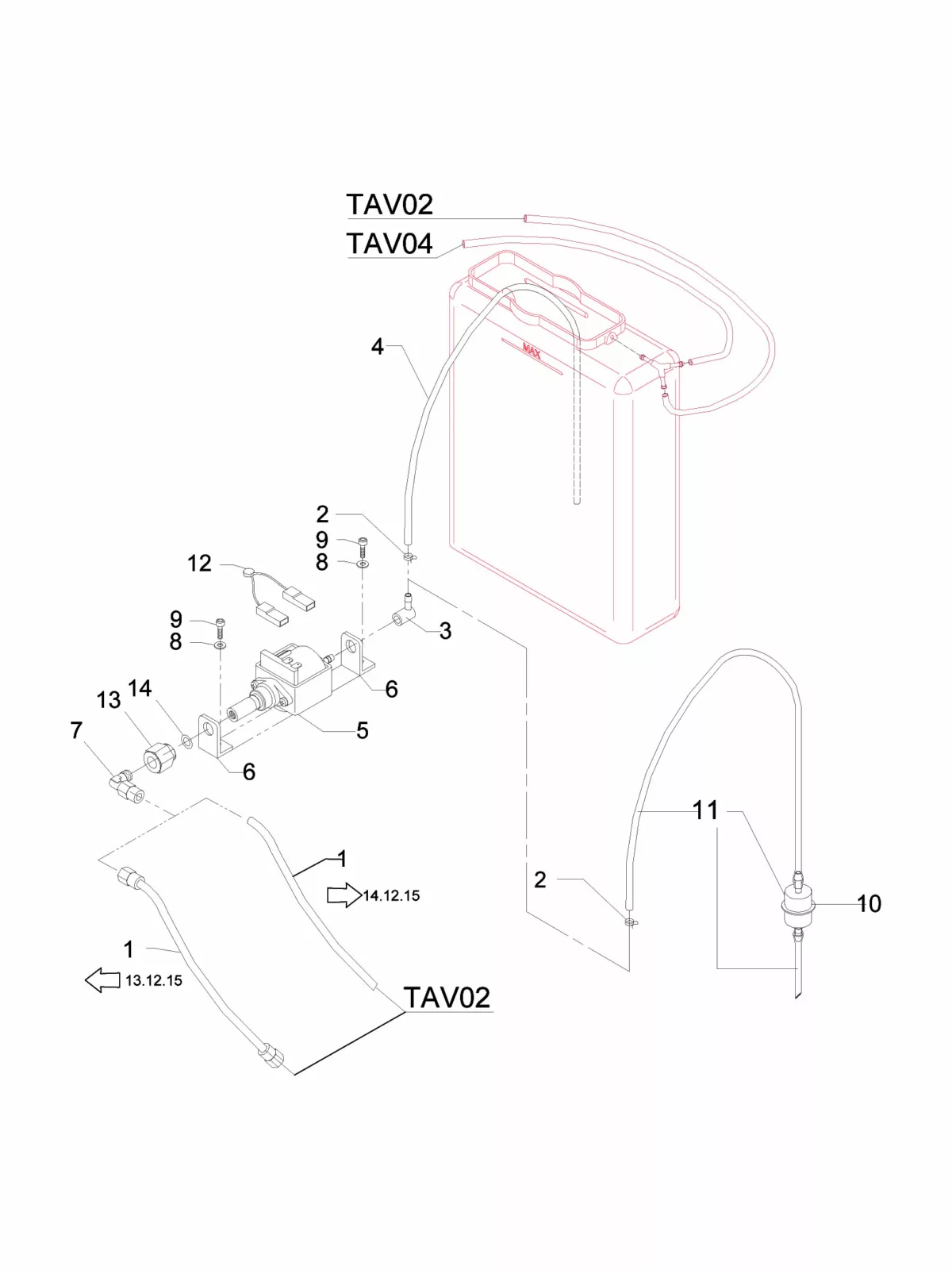

- The heat exchanger has a 1.0 liter boiler which is smaller when you compare to the larger 1.9-liter boilers found on the Super models.

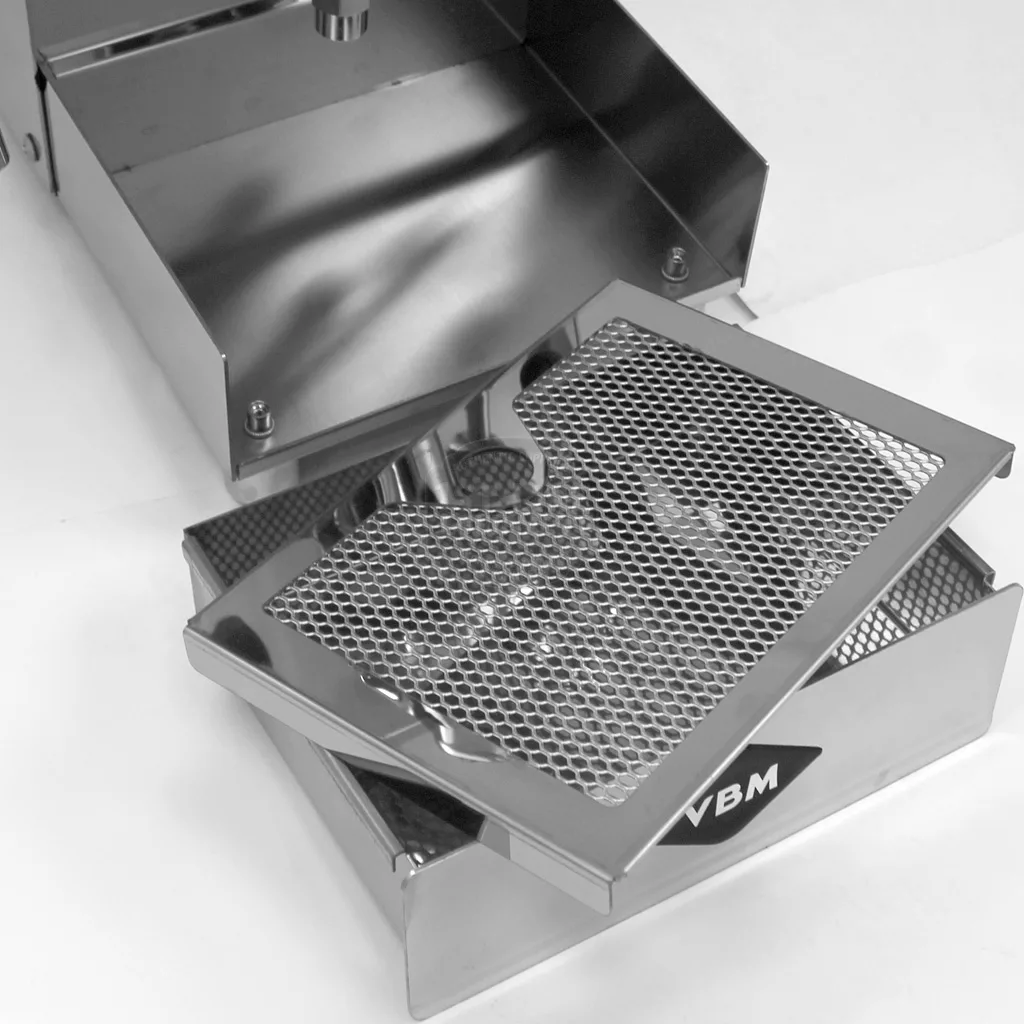

- The drip tray is smaller on the Junior.

- The grouphead and water tank switches are smaller.

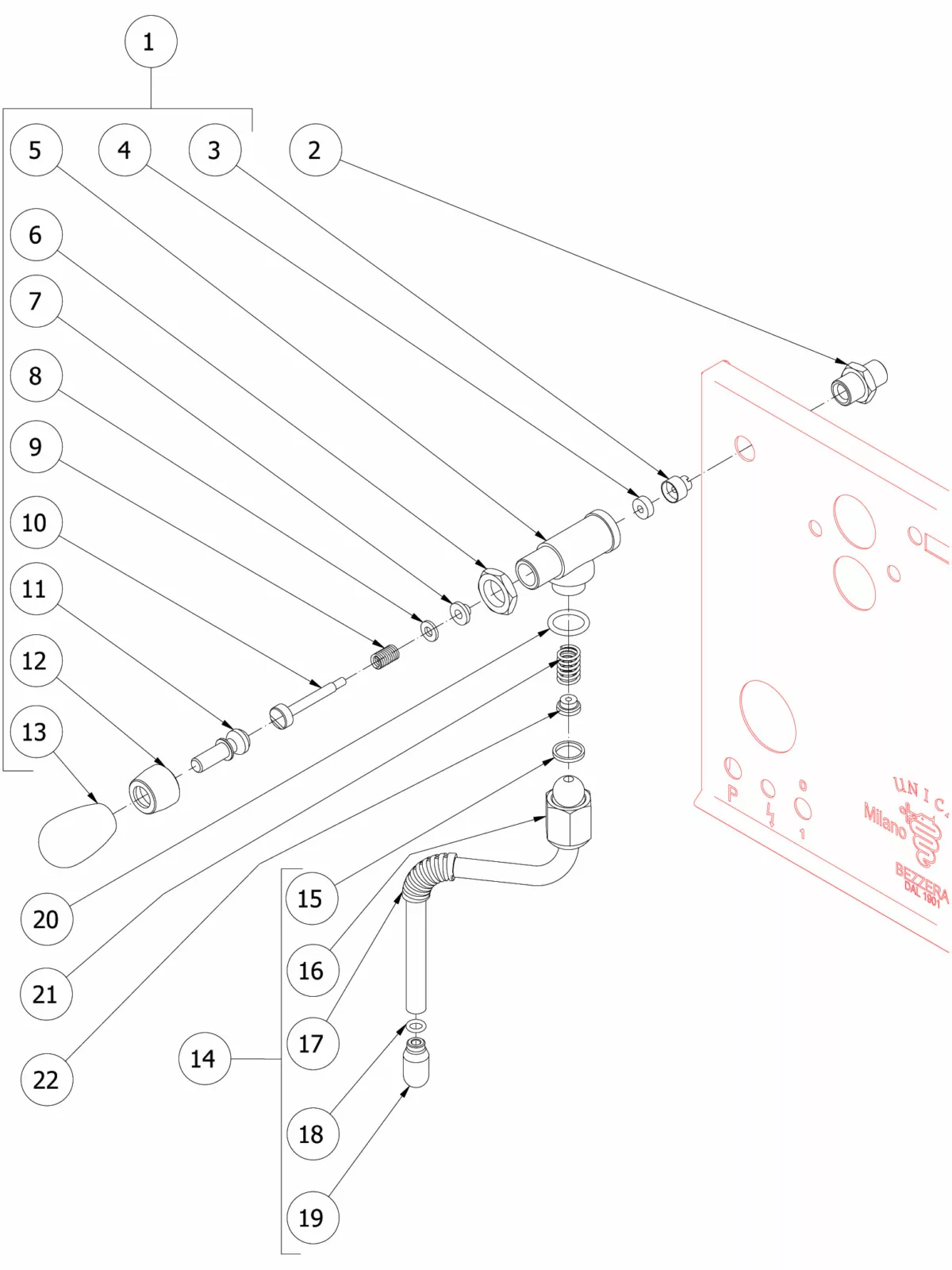

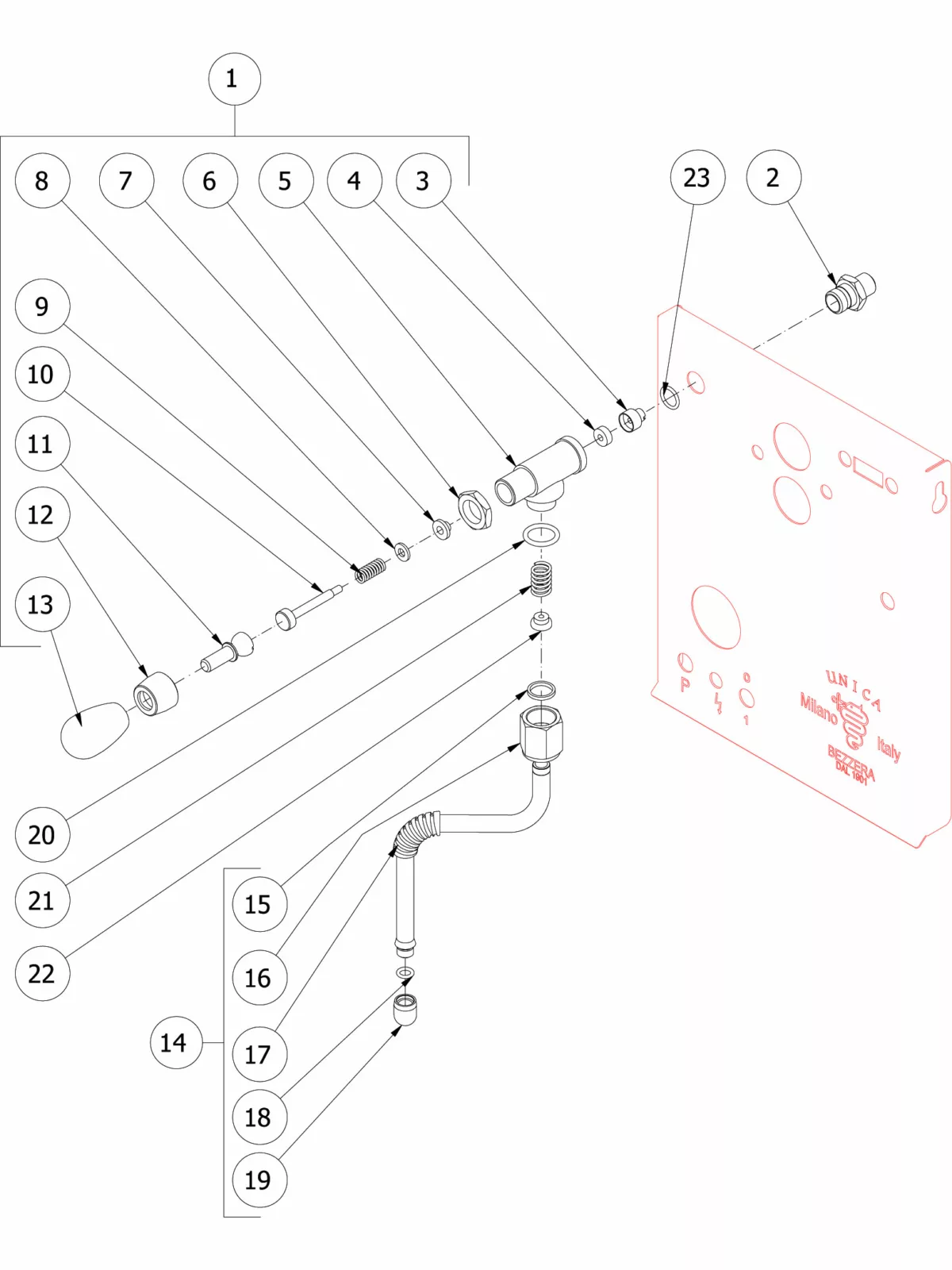

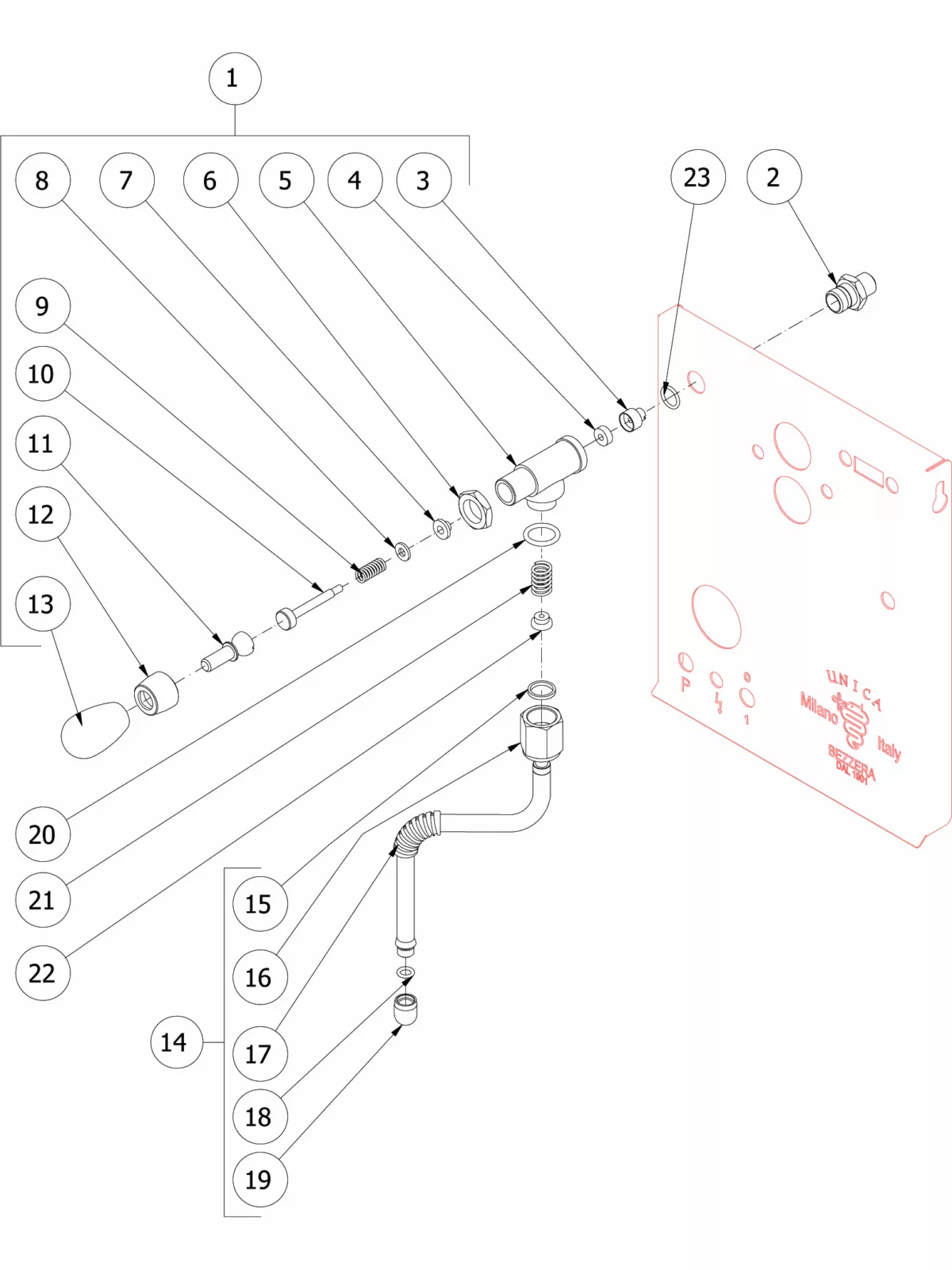

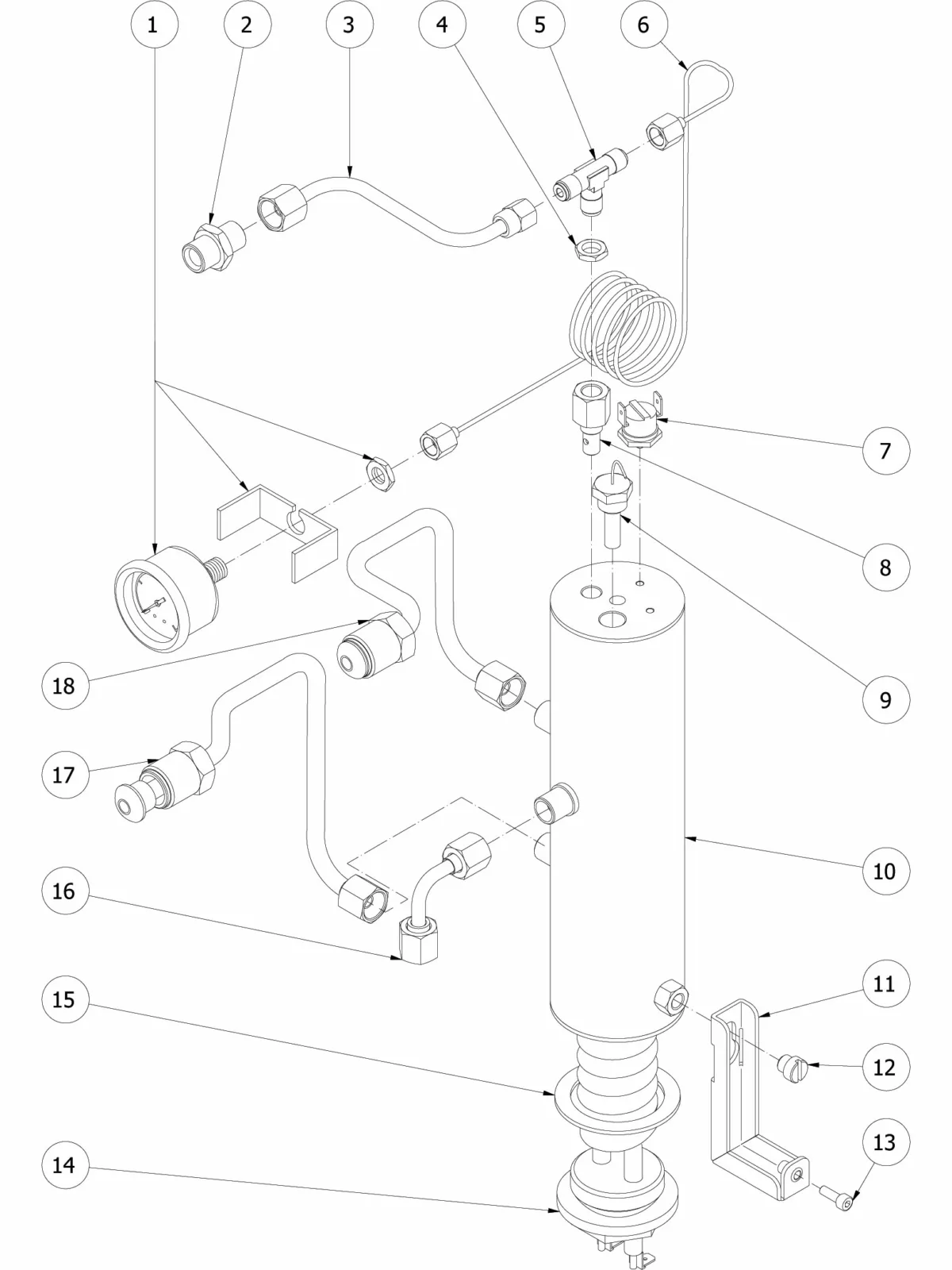

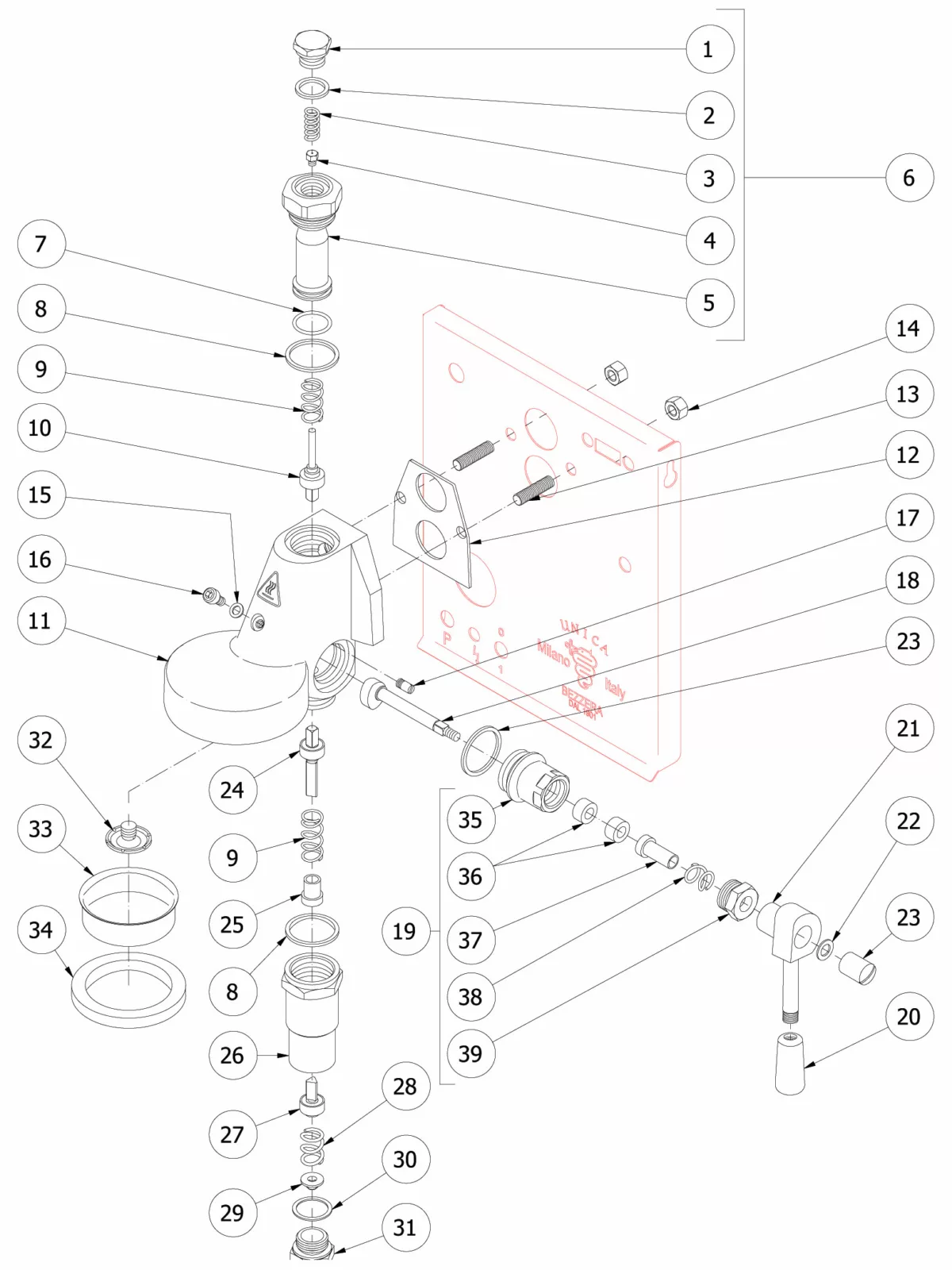

The VBM Domobar Junior HX machine still boasts the exclusive and original E-61 grouphead found on the larger machines, the same ULKA 41 watt pump, gorgeous styling, large adjustable overpressure valve (OPV), commercial-grade steam and hot water valves, multi-directional steam and hot water wands, brew and steam pressure gauges, heavy vacuum breaker valve, and one-way valve to eliminate back pressure from the boiler.