VBM Domobar Junior HX Espresso Machine

Overview:

Enjoy a great latte or creamy cappuccino from a VBM Domobar Junior espresso machine. VBM calls it ‘Junior’ because of its smaller footprint for those customers who do not have the room nor space for the larger Super espresso machines, such as a model with a rotary vane pump or the other with a vibration pump.

A little history… based on the great success of the VBM Domobar Super Heat Exchanger (a.k.a. HX) espresso machines in the USA since 2006, VBM has designed the VBM Domobar Junior HX in 2010 for those customers who need a smaller footprint. The VBM Domobar Junior HX offers the same

- ability to extract espresso and steam milk at the same time, and

- ability to change the pressure in the boiler which is a direct proportional relationship to the temperature.

Please note:

for VBM to offer a lower price when you compare to the Super machines, the following features are different mostly due to the smaller space available inside the machine

- The VBM Domobar Junior’s footprint is smaller for those customers who have less space, but smaller size means less metal (lower cost).

- A smaller pressurestat controls the boiler. This part requires manual descaling.

- The heat exchanger has a 1.0 liter boiler which is smaller when you compare to the larger 1.9-liter boilers found on the Super models.

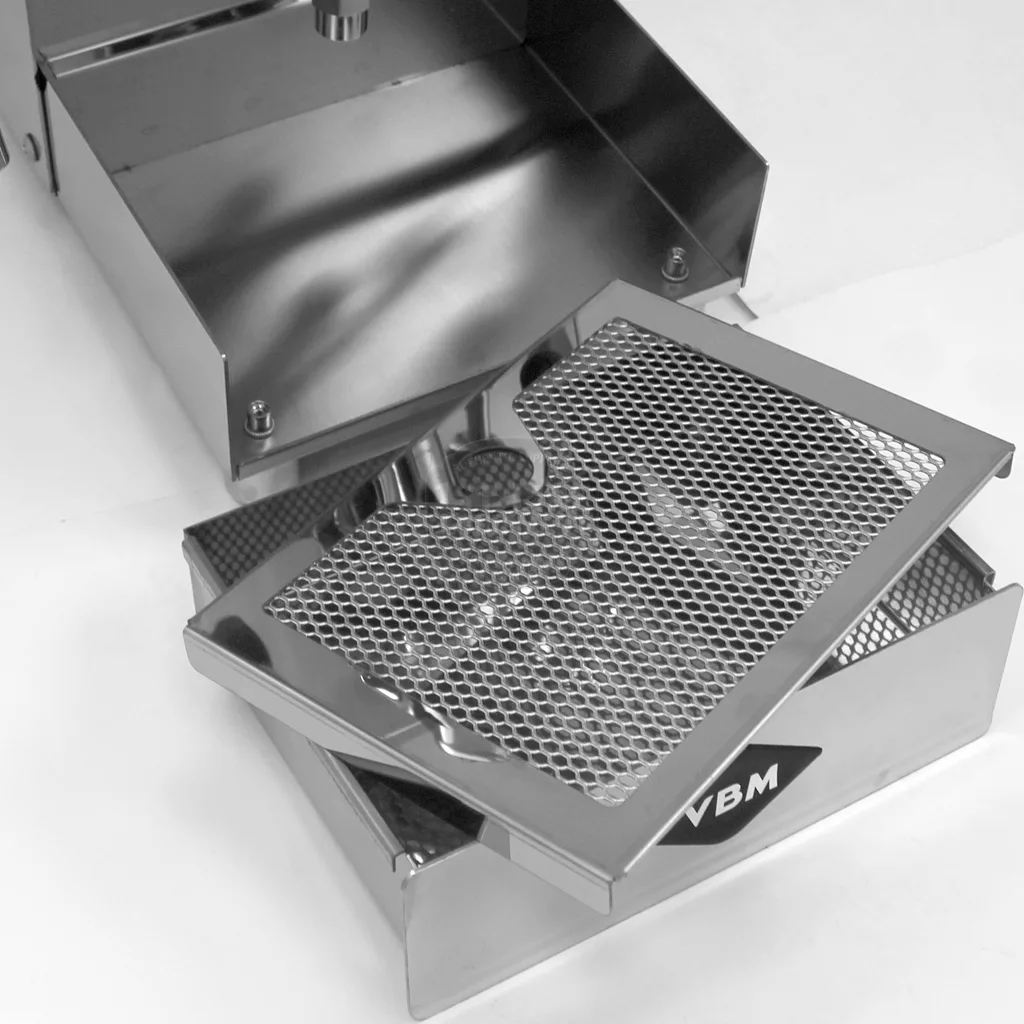

- The drip tray is smaller on the Junior.

- The grouphead and water tank switches are smaller.

The VBM Domobar Junior HX machine still boasts the exclusive and original E-61 grouphead found on the larger machines, the same ULKA 41 watt pump, gorgeous styling, large adjustable overpressure valve (OPV), commercial-grade steam and hot water valves, multi-directional steam and hot water wands, brew and steam pressure gauges, heavy vacuum breaker valve, and one-way valve to eliminate back pressure from the boiler.

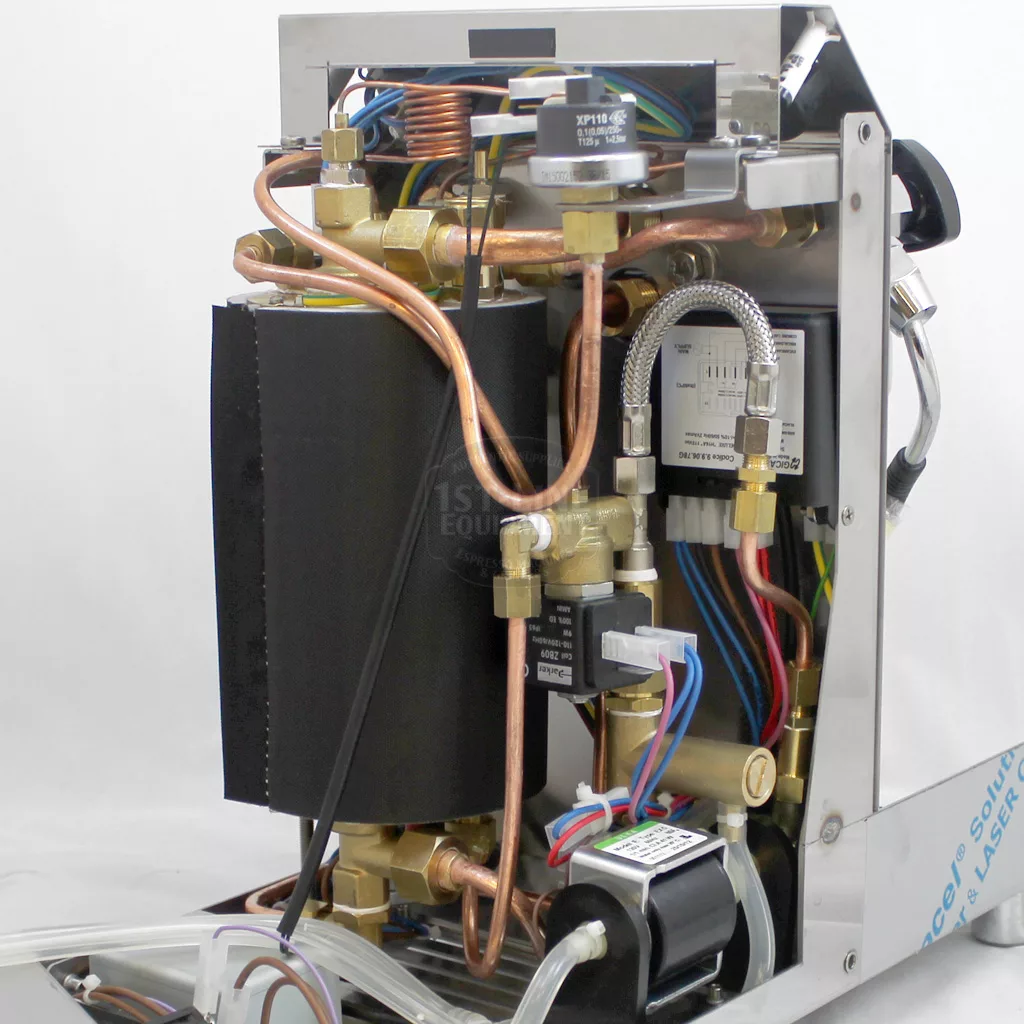

Heat exchange system:

- Copper, insulation – The boiler is copper which retains heat better than stainless steel. Typically copper boilers are more susceptible to limescale when you compare to stainless steel boilers. Therefore, we highly recommend using a water softener. The manufacturer wraps the boiler with insulation for maximum heat retention.

- Pull a shot & steam milk at the same time – Steam is always readily available. Hence, there is no wait time going from coffee to steam mode.

E-61 grouphead:

- True Faema E-61 – The original E-61 by Carlo Ernesto Valente who brought the design from Faema to VBM. More heavy-duty than other E-61 groupheads on the market.

- Constantly heated – Hot water circulates from the heat exchanger through the grouphead and back to keep the grouphead and your portafilter nice and hot. As a result the grouphead temperature constant and stable when you compare to other groupheads that have a built-in heating element.

- Pre-infusion – Lever next to the grouphead activates a microswitch which turns on the pump to pump water through the coffee grinds. Pulling the lever halfway up will open the valve to allow water into the grouphead without activating the pump. Please note that true pre-infusion requires the direct water connection whereby the water pressure from the waterline creates true pre-infusion.

Vibratory pump:

- Efficient – 41 watts, rated up to 15 bar with air valve bypass. You only need 9 bar to extract perfect espresso, and wattage has no correlation to longevity.

- Cost-effective – Pumps will degrade in performance over time. Replacing a vibration pump will cost less than a rotary vane pump.

Tank/reservoir system:

- Particle filter – Protects the machine from any unseen particles from entering the boiler. You can remove this filter if you are installing an inline water softener.

- Auto-shutoff – Prevents burning out the heating element. The water tank sits on a spring-activated plate. Once the water is low, the plate depresses the tank microswitch which turns off the heating element.

Separate wands for steam and hot water:

- Multi-directional – Allows for more movement and flexibility. The wands connect to the valves on an angle to the side for even more flexibility. As a result, there is less risk of burning oneself from the exposed grouphead.

- 2-hole steam tip – Allows for a slow gradual build-up of microfoam.

- Rotational knobs – Allows for easier control of the intensity.

Separate pressure gauges:

- Steam (boiler) pressure gauge – Located on the left. Measures from 0 to 4 bar. Optimal pressure is between 0.8 and 1.1. Regulated by a Mater pressurstat.

- Brew (pump) pressure gauge – Located on the right. Measures from 0 to 16 bar. Optimal pressure is between 8 and 10. You can find the overpressure valve inside the left near the vibration pump.

Separate indicator lights:

- Heating light – Located on the left side. It indicates when the espresso machine is heating. Once fully heated, there is no need to pay attention to the heating light unless temperature surfing.

- Low water level light – Located in the middle. It indicates when the water level in the water tank/reservoir is low.

- Power indicator light – Located on the right side. This will indicate when the machine is on.

Body panel:

- Stainless steel – Polished to a mirror finish.

- Easily removable – First remove the top cover. Then remove the 6 screws (3 on each side) and the wrap-around body slides off.

Accessories included:

- Portafilters – Single spout portafilter and a dual spout portafilter. The neck has the VBM brand imprint, similar to the one on the grouphead.

- Filter baskets – 1-cup filter basket which holds approximately 7 grams. 2-cup filter basket which holds approximately 14 grams. Blind filter basket which you use for backflushing. 58 mm in diameter.

- Tamper – A cheap plastic tamper. Manufacturers will normally include a tamper like this to keep the overall selling price of the machine low. We recommend upgrading to a better tamper.

- Cleaning brush – A simple brush for cleaning the grouphead. Ergonomically designed with an angle for easier usage.

- Coffee scoop – A simple plastic scoop if you are using preground coffee.

- Instruction manual – 3 separate manuals: a quick start guide, a detailed instruction manual, and a description of the machine components.

Are you actually interested in an espresso machine that allows you to steam for the occasional latte or cappuccino? Then take a look at the VBM Domobar Original!

Backflushing

Backflushing Descaling

Descaling Water softening

Water softening Heating element

Heating element Portafilter / grouphead gasket

Portafilter / grouphead gasket Pump

Pump Shower / dispersion screen

Shower / dispersion screen Water tank / reservoir

Water tank / reservoir

7 reviews for DISCONTINUED – VBM Domobar Junior HX Espresso Machine