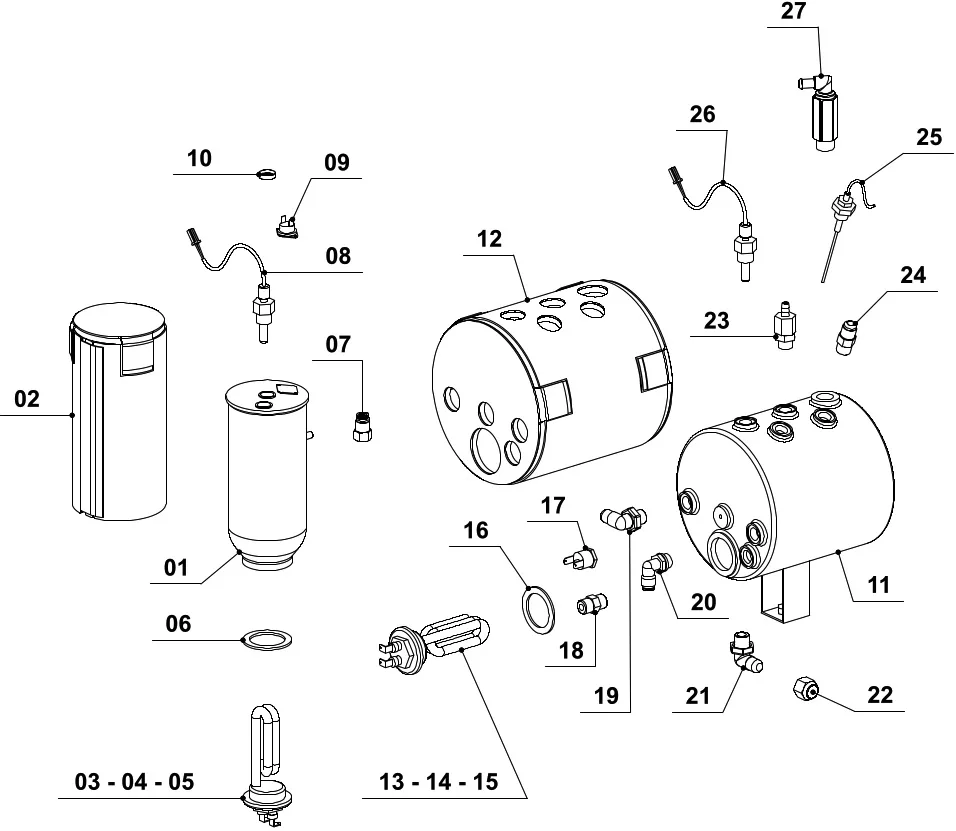

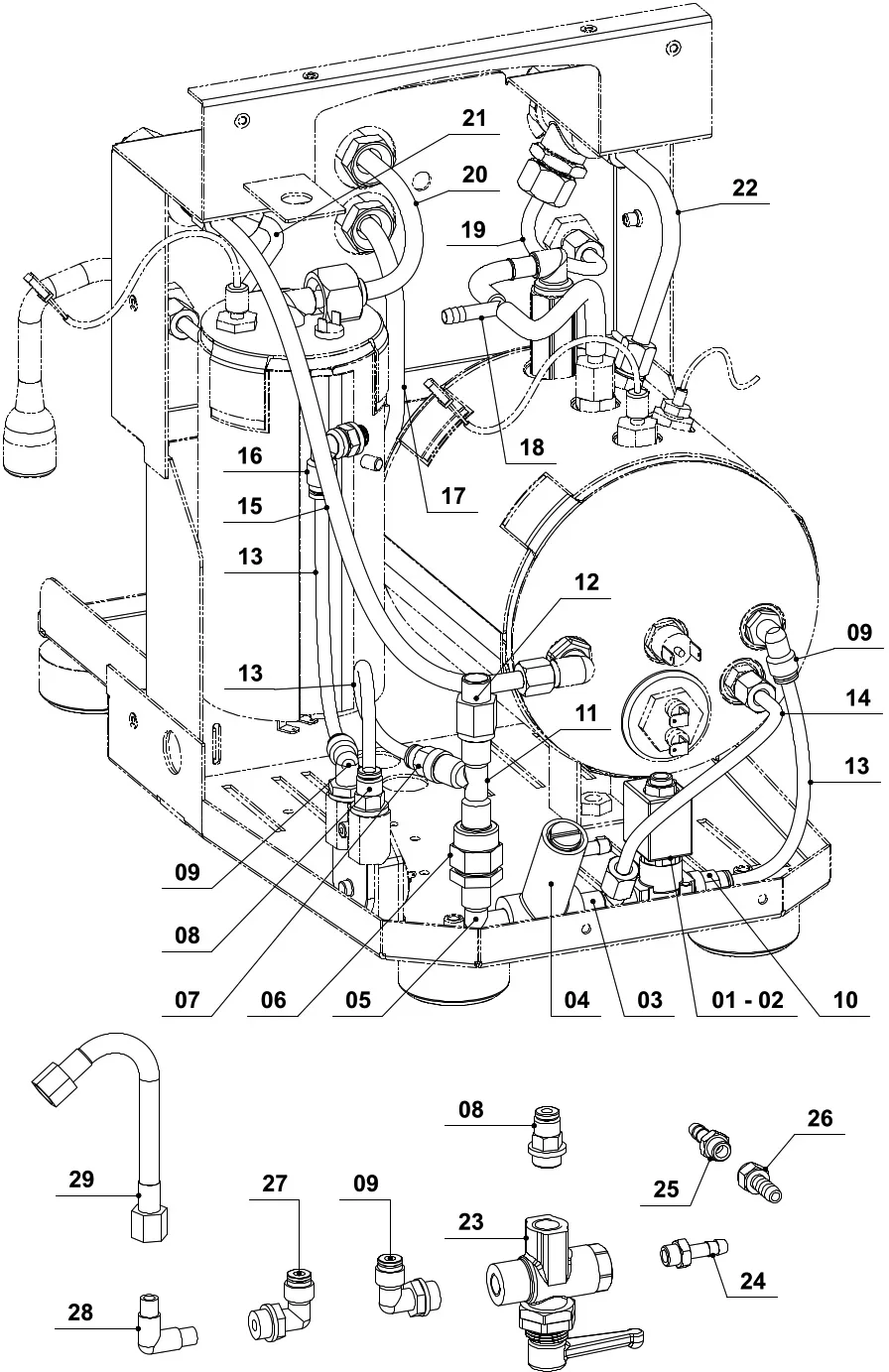

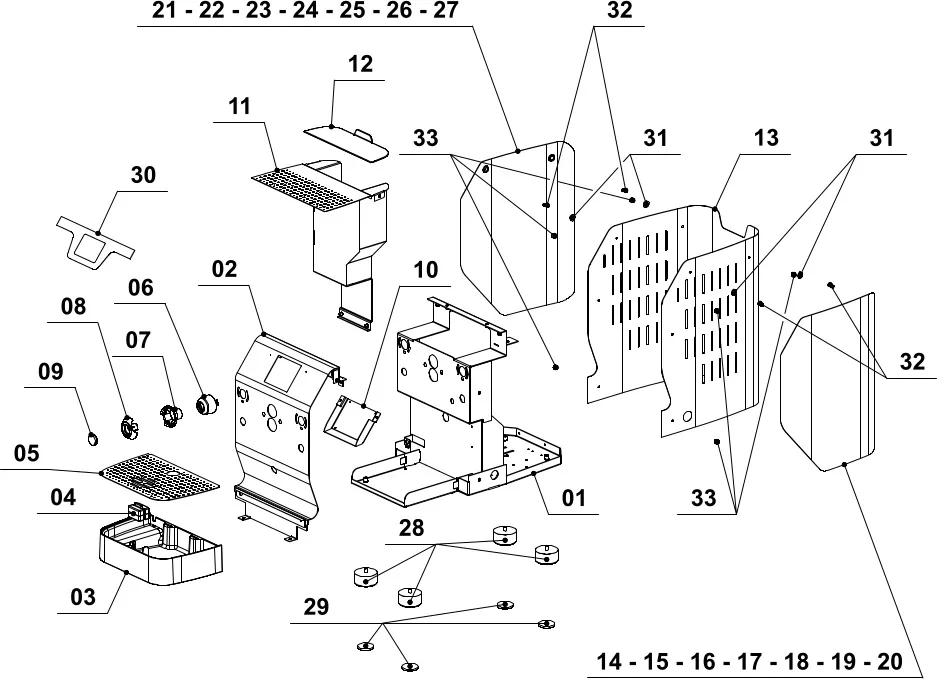

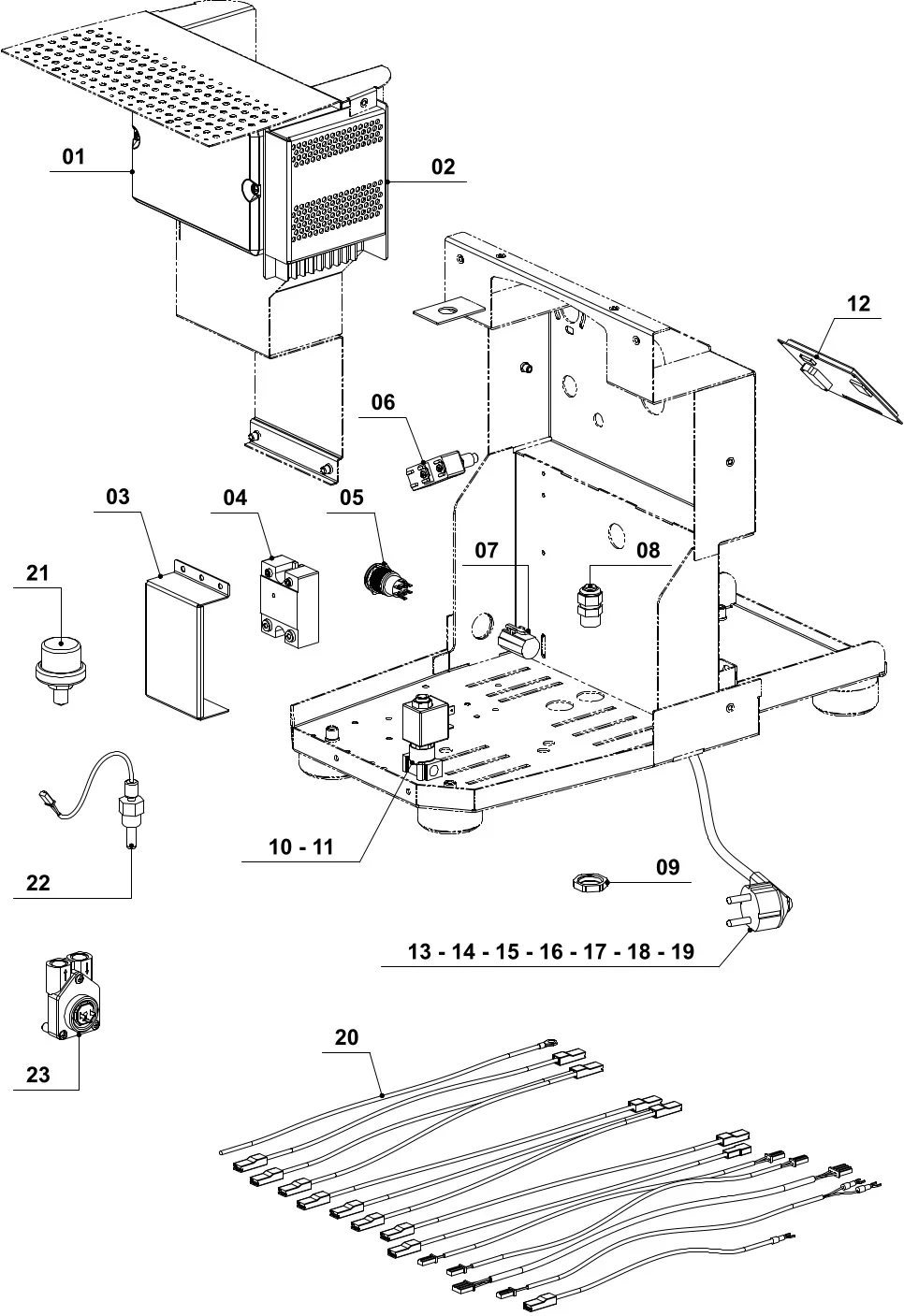

Dual boiler machine with customizable side color panels and a touch screen panel with the capability of “Dual Profiling.”

What is “Dual Profiling?” This is the capability to program pump pressure shot profiling as well as a flow control profile device on top of the grouphead to fine-tune on the fly!