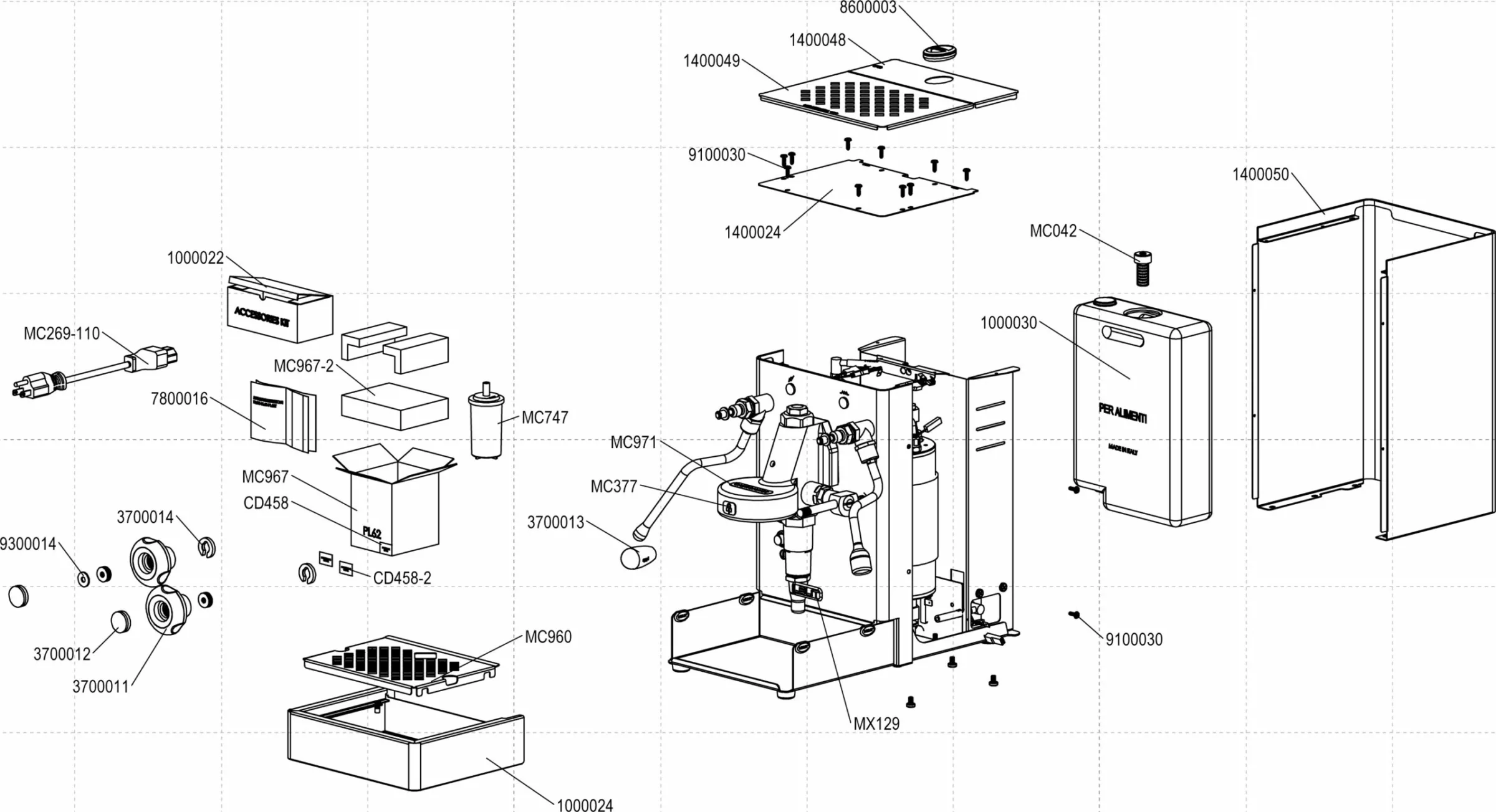

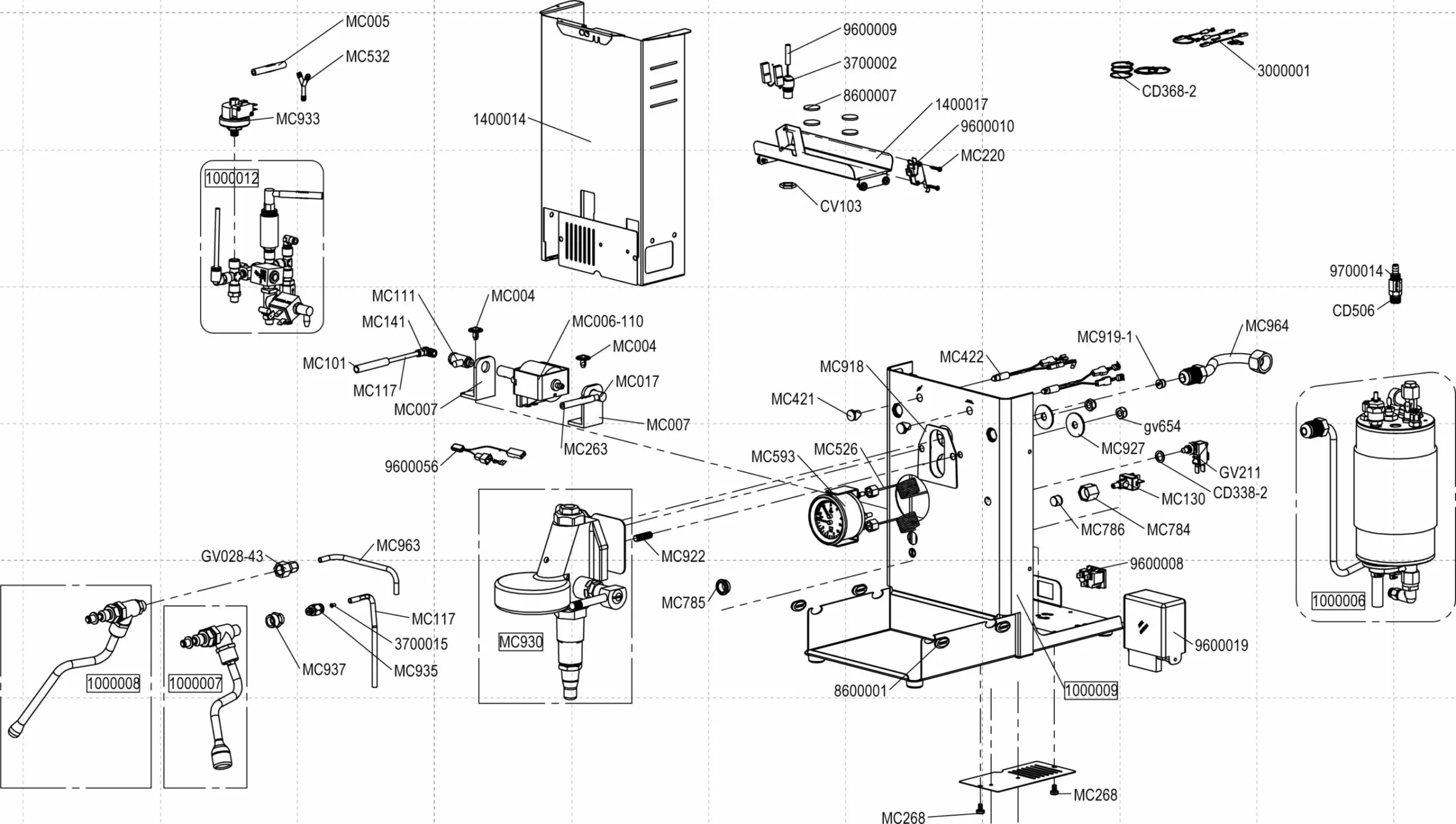

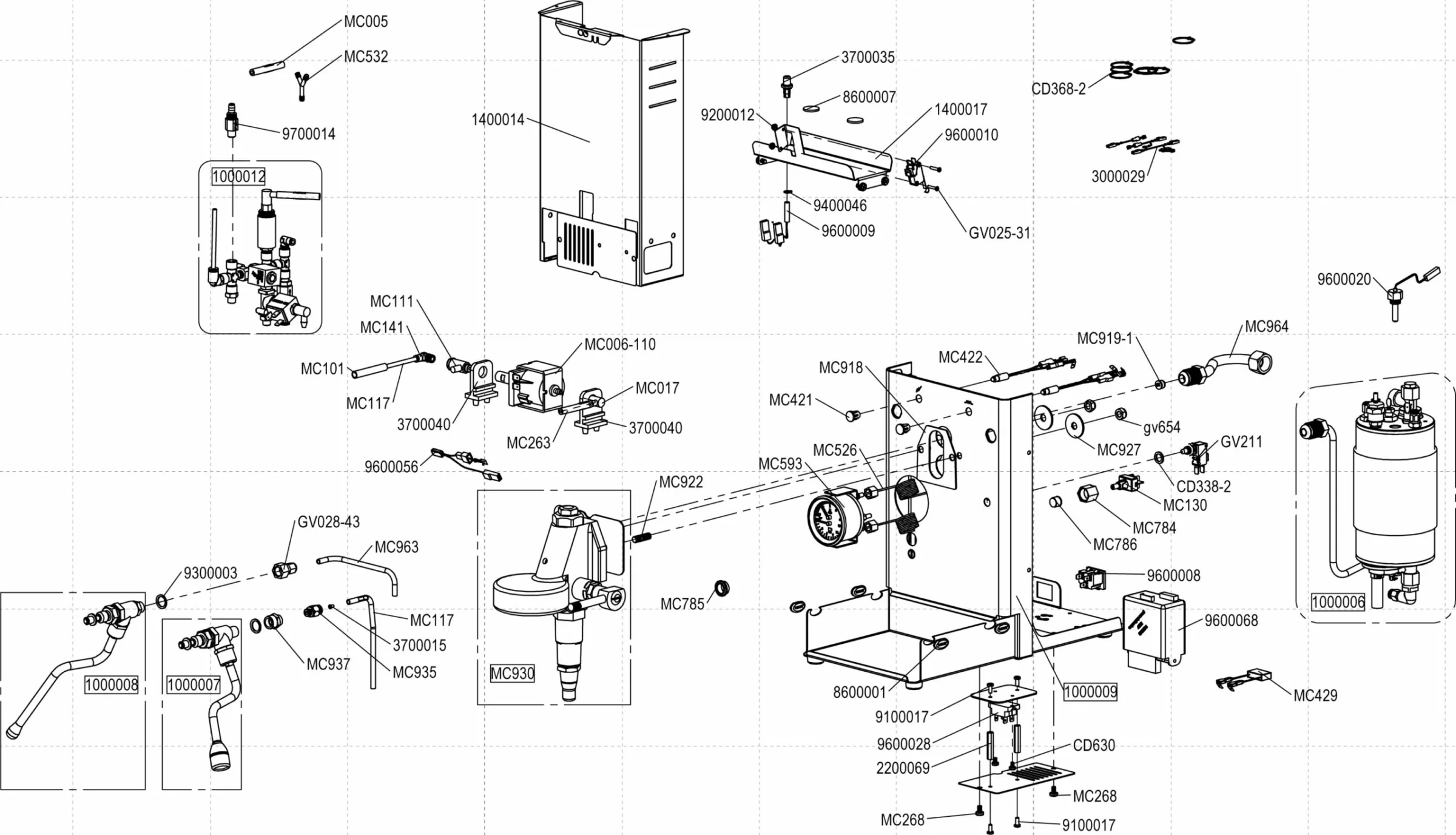

Lelit PL62S Mara HX Espresso Machine

A huge legend in a small body. The Lelit PL62S Mara is placed at the prestigious end of many home espresso machines. It combines the best technology ever – the legendary E61 grouphead inside an incredibly compact, full stainless steel body. The result: a marvelous, appealing and super compact espresso machine enabling to apply barista’s golden rules and extract the most tasty espressos and cappuccinos you can dream of.