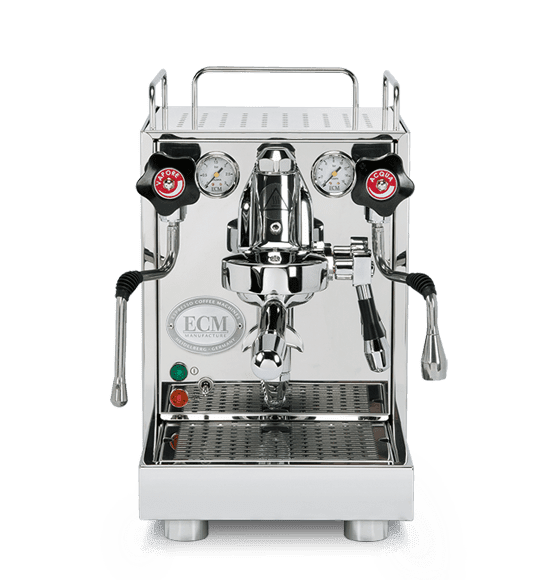

ECM Mechanika V Slim Espresso Machine

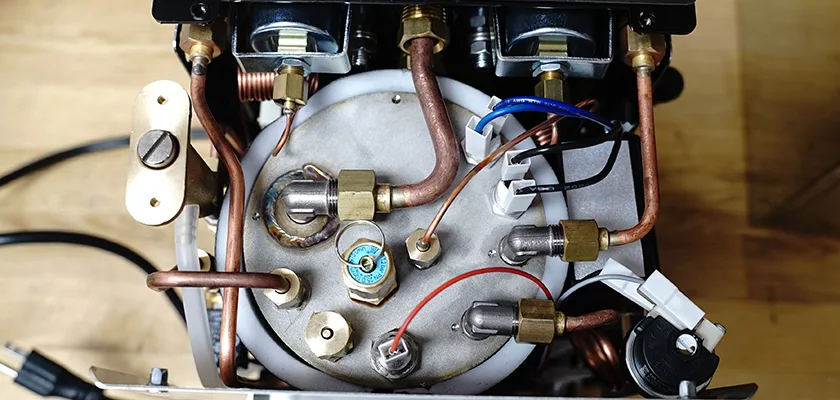

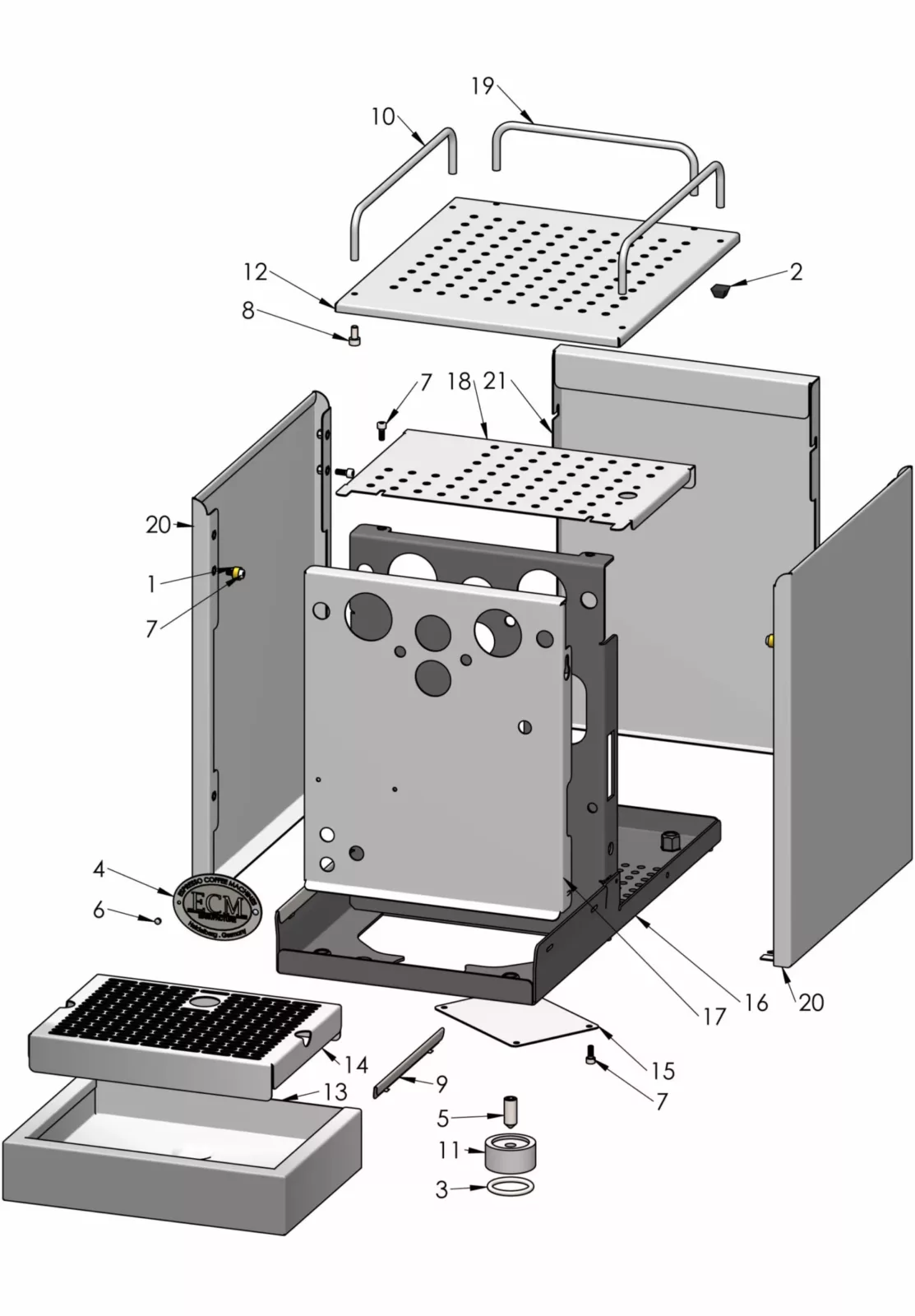

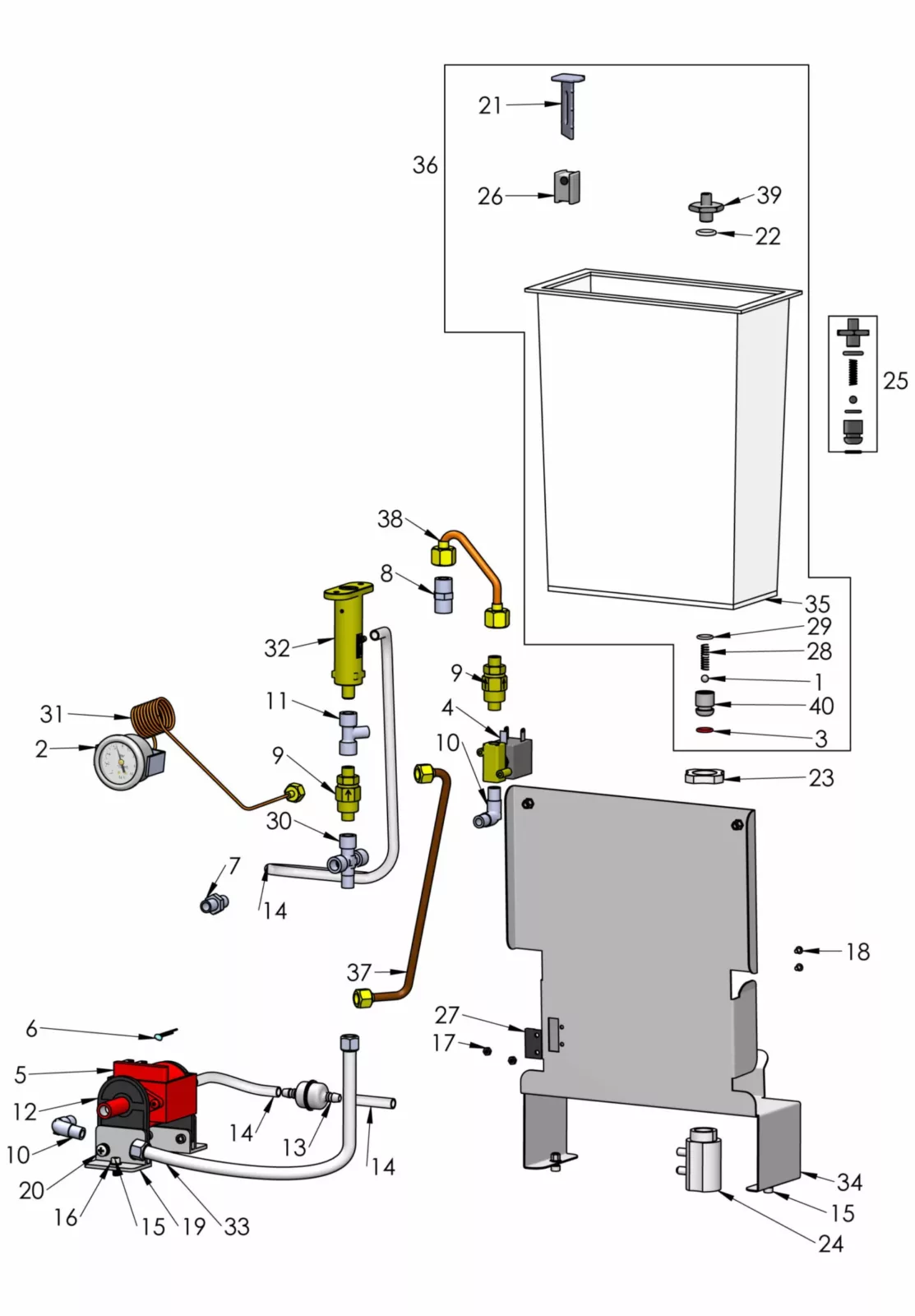

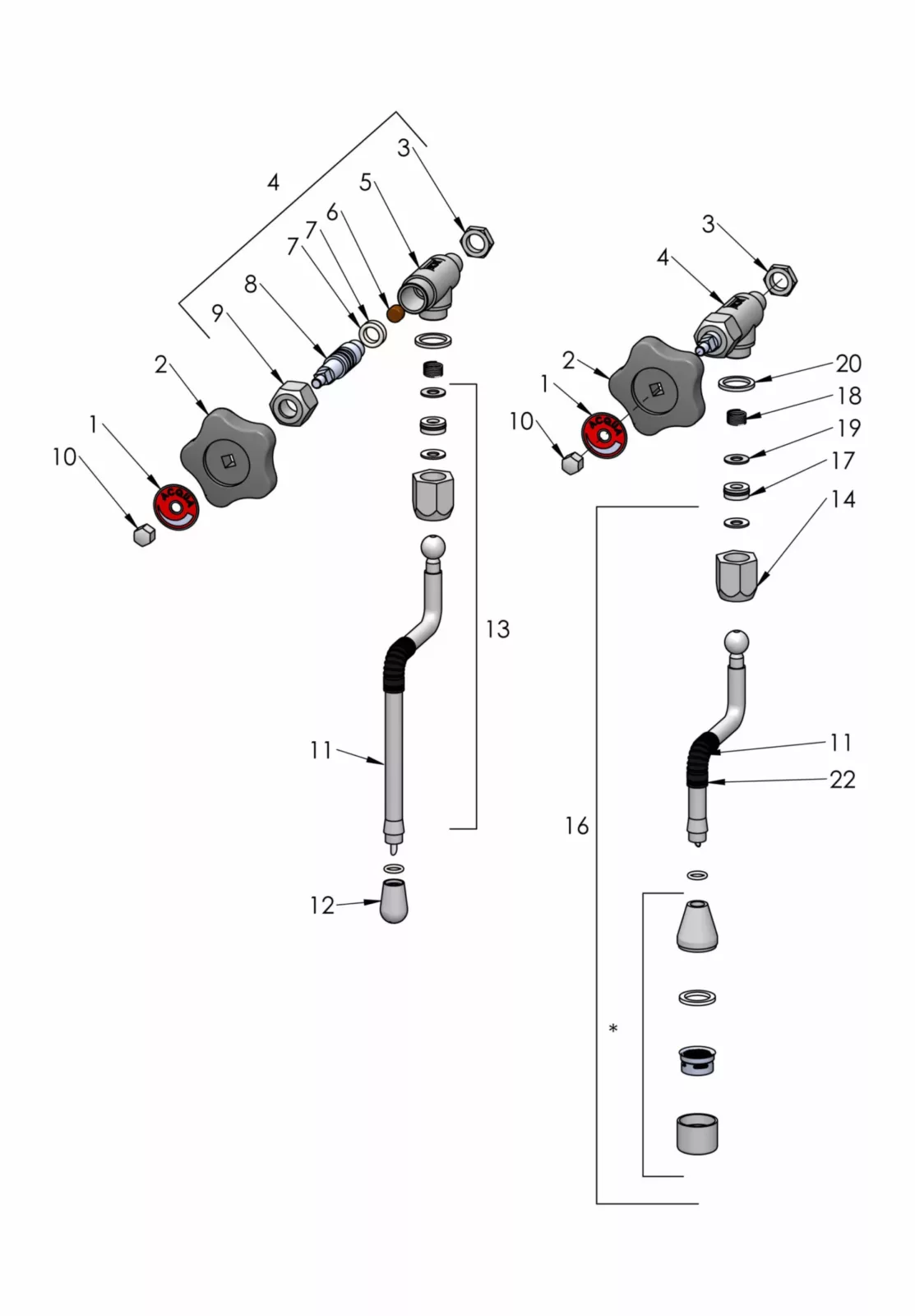

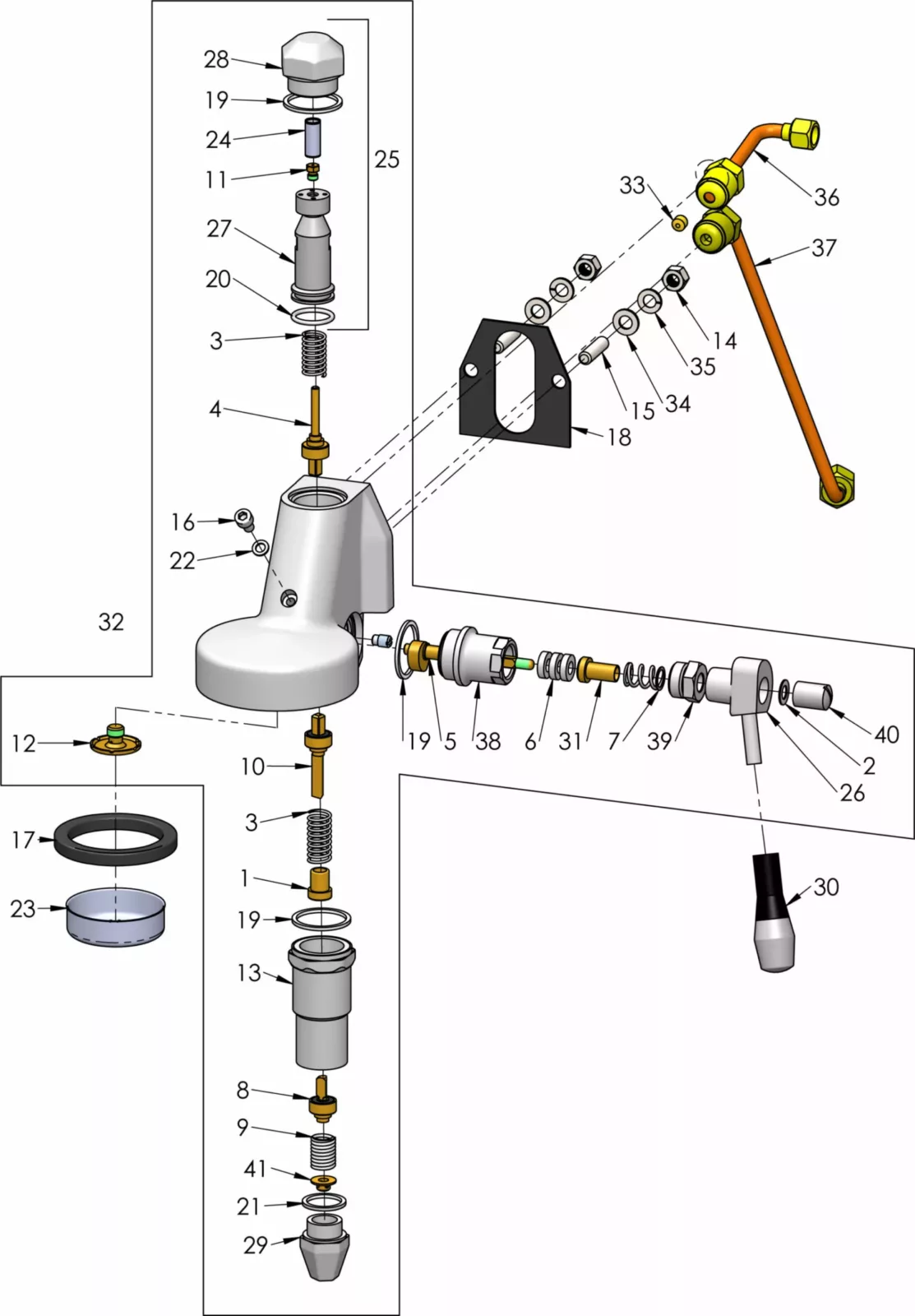

The Mechanika V Slim is ECM’s modern HX commercial espresso machine that consists of advancements in elegant looks and technological boosting compared to the previous Mechanika Profi IV. This model also slimmed down a bit (hence, its name is the Slim) since it is only 10 inches wide and changed the shape of the boiler, which can go to a maximum of 2.2 L. The Mechanika V Slim features stunning steel legs, inscribed ECM in steam and hot water valves, separate steam and brew pressure gauges, single spout and dual spout portafilters, removable drip tray, and E61 grouphead.