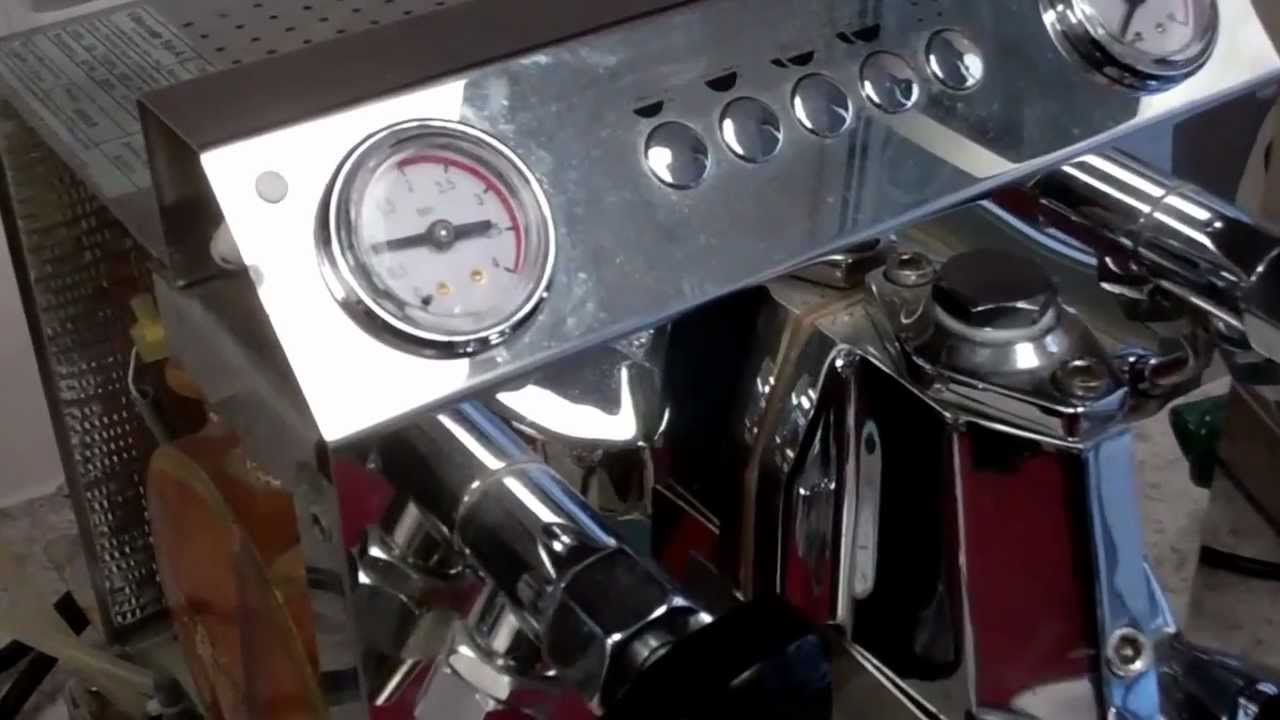

General Espresso Machine Notes/Warnings:

- Upon first use (tank/reservoir models): On the initial start-up (or after a long period of non-use), it is important to make sure the pump is removing water from the tank. When the machine is powered on, you will hear the pump running. After 5 seconds, squeeze the in-line hose in the tank (usually the longest hose, has a particle filter attached). if you hear a different sound, this means the pump is working correctly. If not, immediately power down the machine and contact us. For more information, visit this page General Manual Pump Priming.

- Electrical: To avoid electrical damage to this espresso machine which is not considered a manufacturer's defect, please acquire and install a single-outlet surge suppressor rated at 1080 joules or higher. Without the recommended surge suppressor, the espresso machine can be damaged at the power switch, the electronics, the heating element, the pressurstat, or the wiring inside. For more information, visit this page Power Protection.

- Water: To increase the useful life and not damage your espresso machine, please use softened water. Softened water is water without calcium and magnesium, but still has other minerals for espresso extraction. Do not use distilled, purified, or reverse osmosis water as these types of water create oxidation with the metals and cause the same damaging effects as limescale. For more information, visit this page Water Choice.

- Descaling: We do not recommend descaling unless there is an issue with the espresso machine. Too much descaling can eat away at the metals and gaskets inside an espresso machine. As a preventative measure, we recommend using softened water as explained in the bullet point above.

- Backflushing: This procedure of cleaning the grouphead will need to be performed from time to time. For more information, visit this page Espresso Machine Backflush – Why 50?