DISCONTINUED ECM Mechanika V Slim Espresso Machine

Check out the newer Mechanika Slim VI.

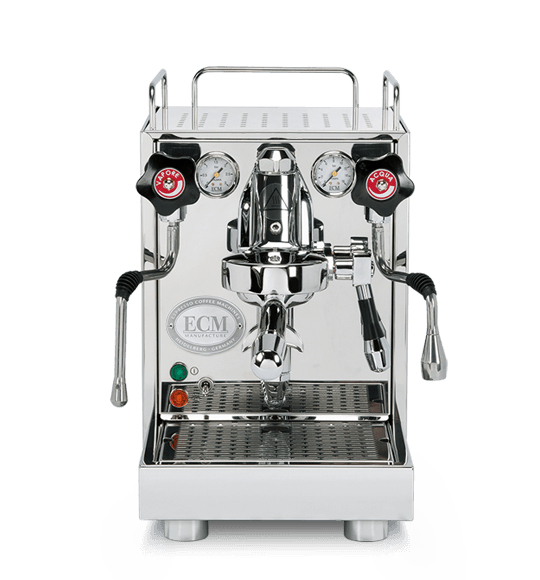

ECM Mechanika V Slim Espresso Machine

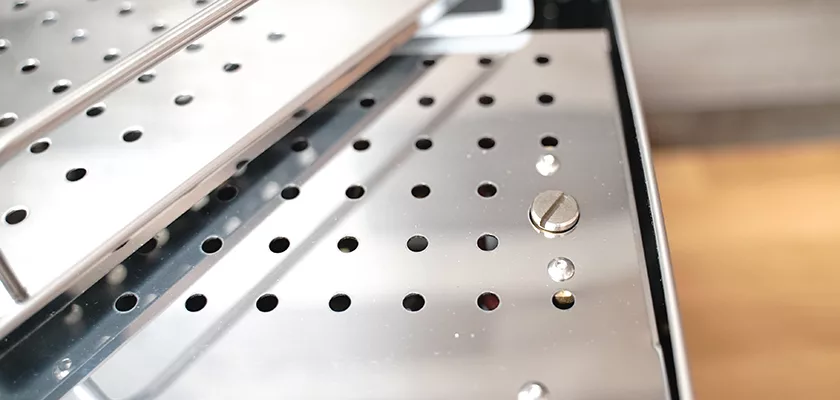

The Mechanika V Slim is ECM’s modern HX commercial espresso machine that consists of advancements in elegant looks and technological boosting compared to the previous Mechanika Profi IV. This model also slimmed down a bit (hence, its name is the Slim) since it is only 10 inches wide and changed the shape of the boiler, which can go to a maximum of 2.2 L. The Mechanika V Slim features stunning steel legs, inscribed ECM in steam and hot water valves, separate steam and brew pressure gauges, single spout and dual spout portafilters, removable drip tray, and E61 grouphead.

New Design

- Slimmer – The Mechanika V Slim is now only 10 inches wide (2 inches less than the Mechanika Profi IV).

- Updates in aesthetics – Other changes in looks include stunning steel legs and inscribed ECM in steam and hot water valves.

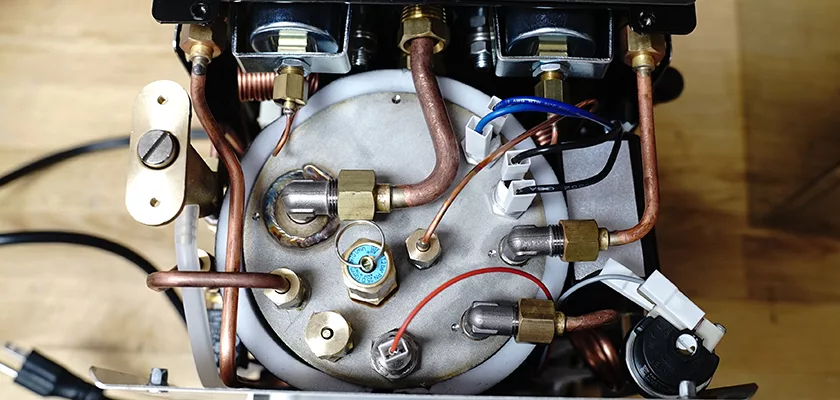

Heat Exchange System

- Stainless steel, insulated – The boiler is made of stainless steel which is less susceptible to limescale. Typically stainless steel boilers do not retain their heat as well as copper or brass boilers. This machine compensates that by being wrapped with insulation.

- Shape change – The heat exchange boiler can now go to a maximum of 2.2 L. The shape change allows for ECM to retain a lot of room on the machine’s interior.

- Pull a shot & steam milk at the same time – Steam is always readily available. Therefore there is no wait time going from coffee to steam mode. Works well if entertaining a small group of people.

Modifiable Brew Pressure

- OPV placement– The OPV on the Mechanika V Slim is located on the top to modify the brew pressure. The valve, which is placed below the reservoir lid, can also be modified simultaneously with the brew pressure gauge to simply create rapid revisions when brewing.

Tank/Reservoir System

- Open top: Easy to fill. Easy to clean.

Separate Pressure Gauges

- Steam pressure gauge – Located on the left. Measures from 0 to 3 bar. Optimal pressure is between 0.8 and 1.1.

- Brew pressure gauge – Located on the right. Measures from 0 to 16 bar. Optimal pressure is between 8 and 10.

E-61 Grouphead

- Constantly heated – Hot water circulates from the heat exchanger through the grouphead and back to keep the grouphead and your portafilter nice and hot. This keeps the grouphead at a constant, stable temperature compared to other groupheads that have a built-in heating element.

- Pre-infusion – The lever next to the grouphead activates a microswitch which turns on the pump to pump water through the coffee grinds. When you pull the lever half way up, it will open the valve to allow water into the grouphead without activating the pump. Please note that true pre-infusion requires the direct water connection whereby the water pressure from the water line creates the true pre-infusion.

Vibratory Pump

- Semi-Quiet Operation – A sturdy and dense asset to any espresso machine to produce the best espresso, although it is slightly louder than rotary pumps

Steam Wand

- Multi-directional – Allows for more movement and flexibility.

- “No burn” – Wand is insulated to allow you to touch anywhere on the arm. Please note that after very long periods of steaming or pouring hot water, the arm will be too hot to touch. We recommend to only touch the rubber grips on each wand.

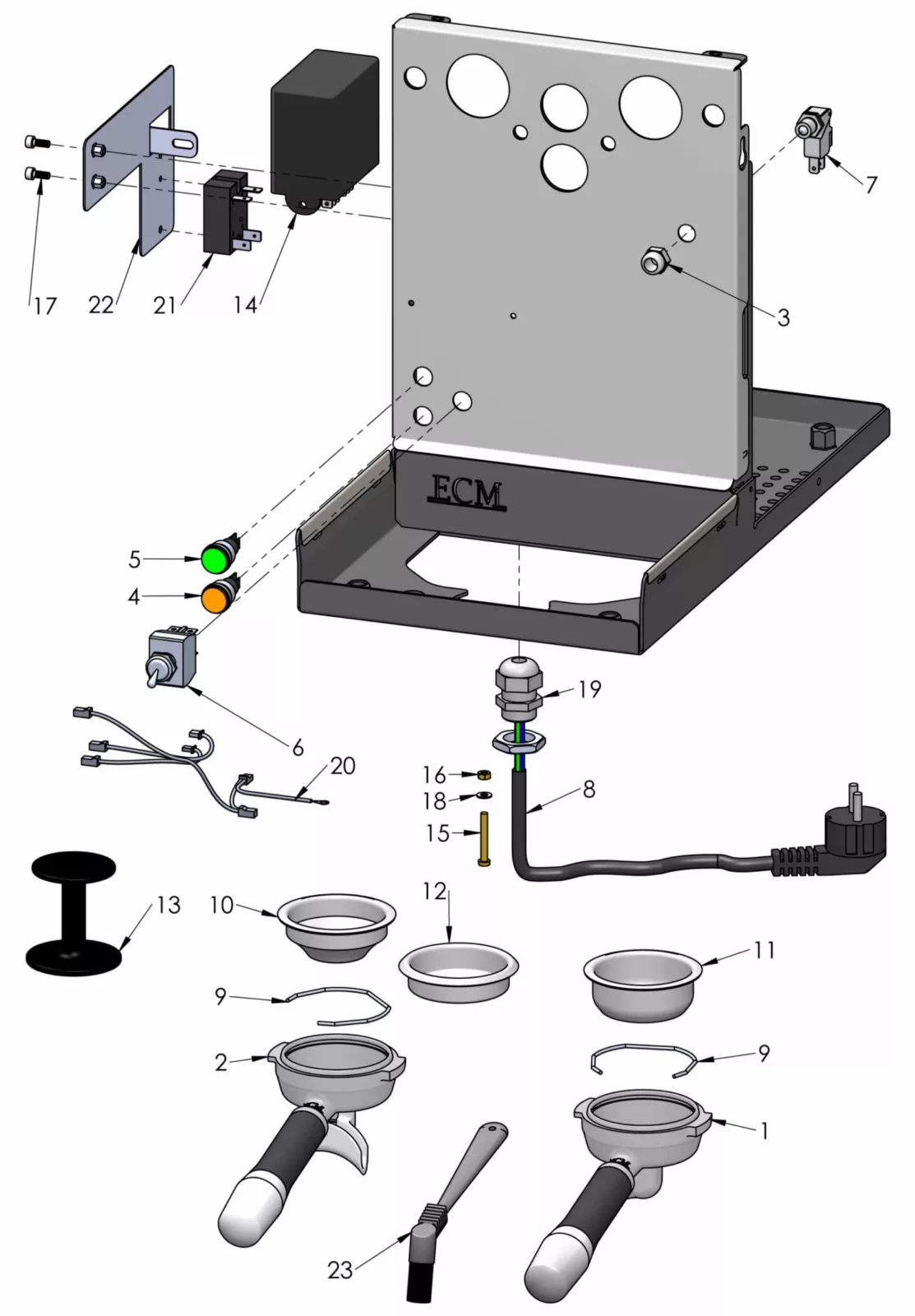

Accessories Included with the ECM Mechanika Slim

- Portafilters – Single spout portafilter and a dual spout portafilter. Both handles match the style of the grouphead lever and are ergonomically designed with an angle for easier operation to lock into the grouphead

- Filter baskets – 1-cup filter basket which holds approximately 7 grams. 2-cup filter basket which holds approximately 14 grams. Blind filter basket which you can use for backflushing. All basket are 58 mm in diameter.

- Tamper – Solid 58mm tamper. No need to upgrade.

- Instruction manual – Written in both German and English. The instructions also work for the Technika.

| Brand | ECM Manufacture |

|---|---|

| Height (inches) | 15.5, approximate |

| Width (inches) | 9.8, approximate |

| Depth (inches) | 17.5, approximate |

| Weight (pounds) | 50 |

| Wattage (watts) | 1400 |

| Voltage (volts) | 110 – 120 |

| Boiler capacity (liters) | 2.2 |

| Portafilter size (mm) | 58 |

| Country of manufacture | Assembled in Milan, Italy, Designed in Germany |

| Approvals | CE |

Espresso Machine Warning:

- ELECTRICAL WARNING: To avoid electrical damage to this espresso machine which is not considered a manufacturer's defect, please acquire and install a single-outlet surge suppressor rated at 1080 joules or higher. the lack of the recommended surge suppressor, the espresso machine can be damaged at the power switch, the electronics, the heating element, the pressurstat or the wiring inside.

- WATER WARNING: To increase the useful life of and not damage your espresso machine, please use softened water. Softened water is water without calcium and without magnesium, but still has other minerals for espresso extraction. Do not use distilled water, purified water, nor reverse osmosis water as these types of water create oxidation with the metals and cause the same damaging effects as limescale.

- DESCALING WARNING: We do not recommend descaling unless there is an issue with the espresso machine. The reason is that too much descaling can eat away at the metals and gaskets inside an espresso machine.

Backflushing - should be performed with detergent minimum every 50 espresso extractions. A short backflush 'can' be performed daily. The paddle on the grouphead should be all the way to the right side of the grouphead.

For optimal performance reducing limescale, use the BILT Osmotic Scale Reduction cloth by removing from the bag, rinsing it under cold water, and placing it in the water tank/reservoir of your espresso machine.

We do not advise descaling as we find machines last longer with limescale prevention. Descaling eats away at the metals and gaskets inside the machine. Thus, the internals weaken from both the scale build up as well as the descaler.

The grouphead gasket and dispersion screen should be replaced every 6-12 months.

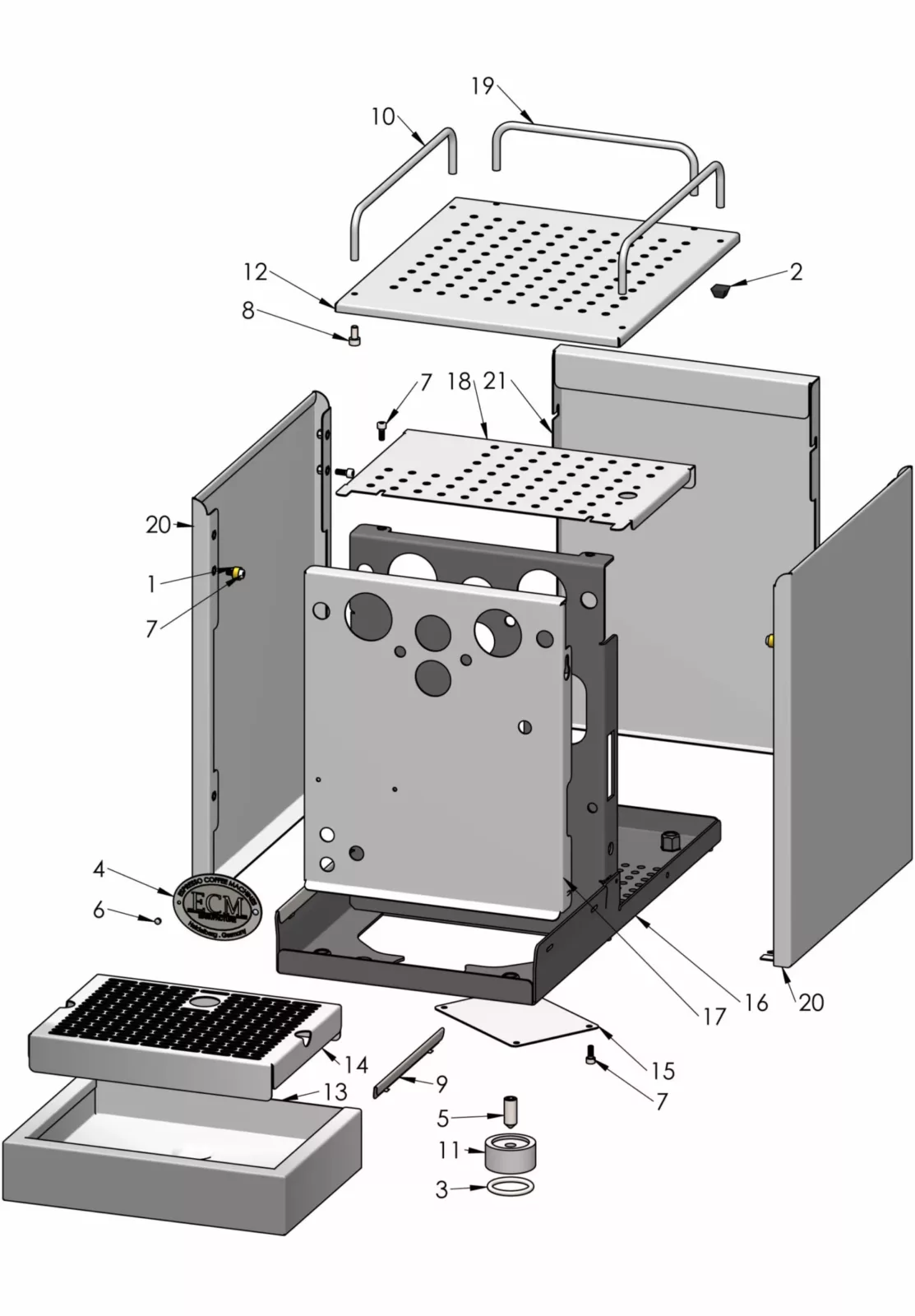

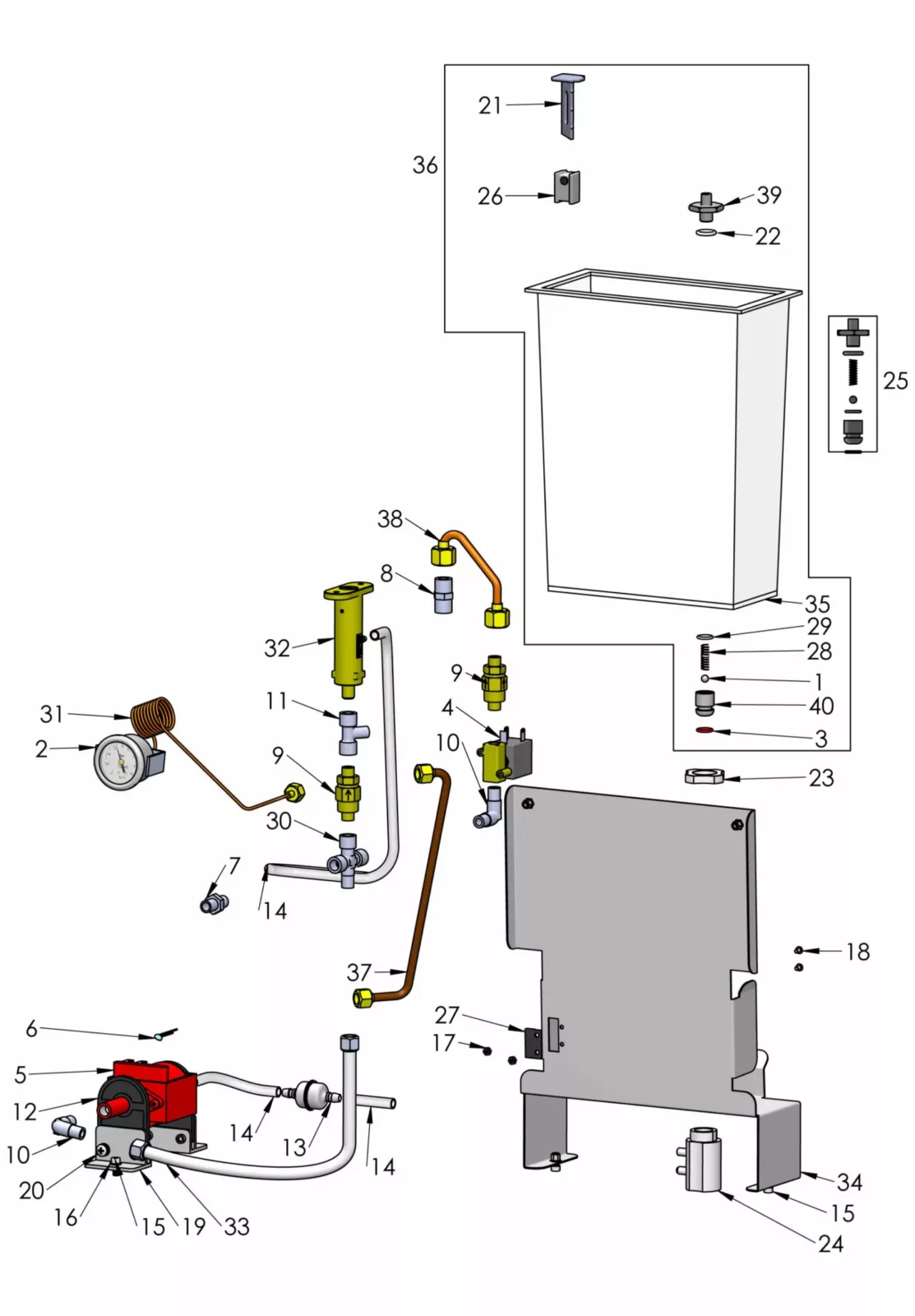

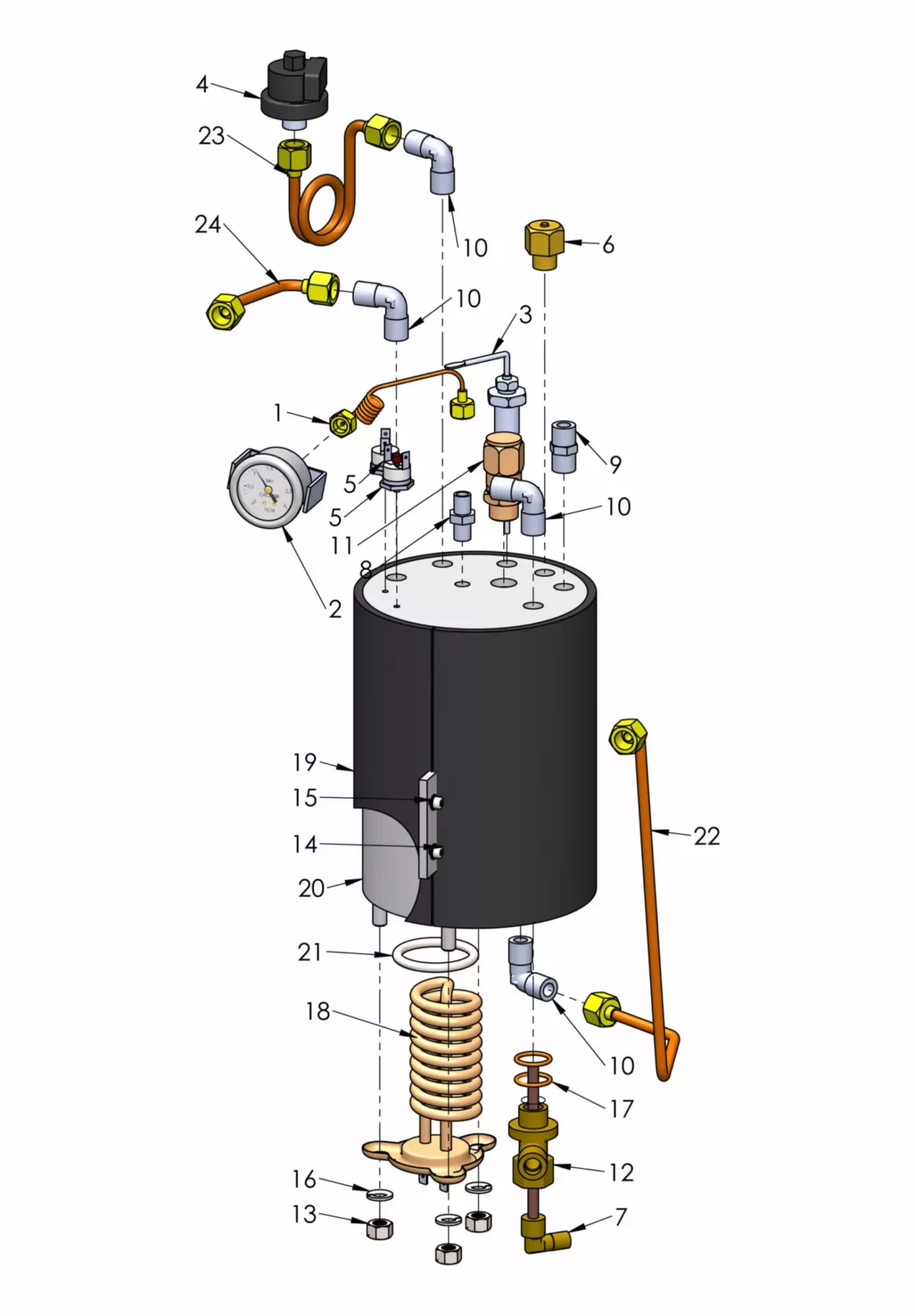

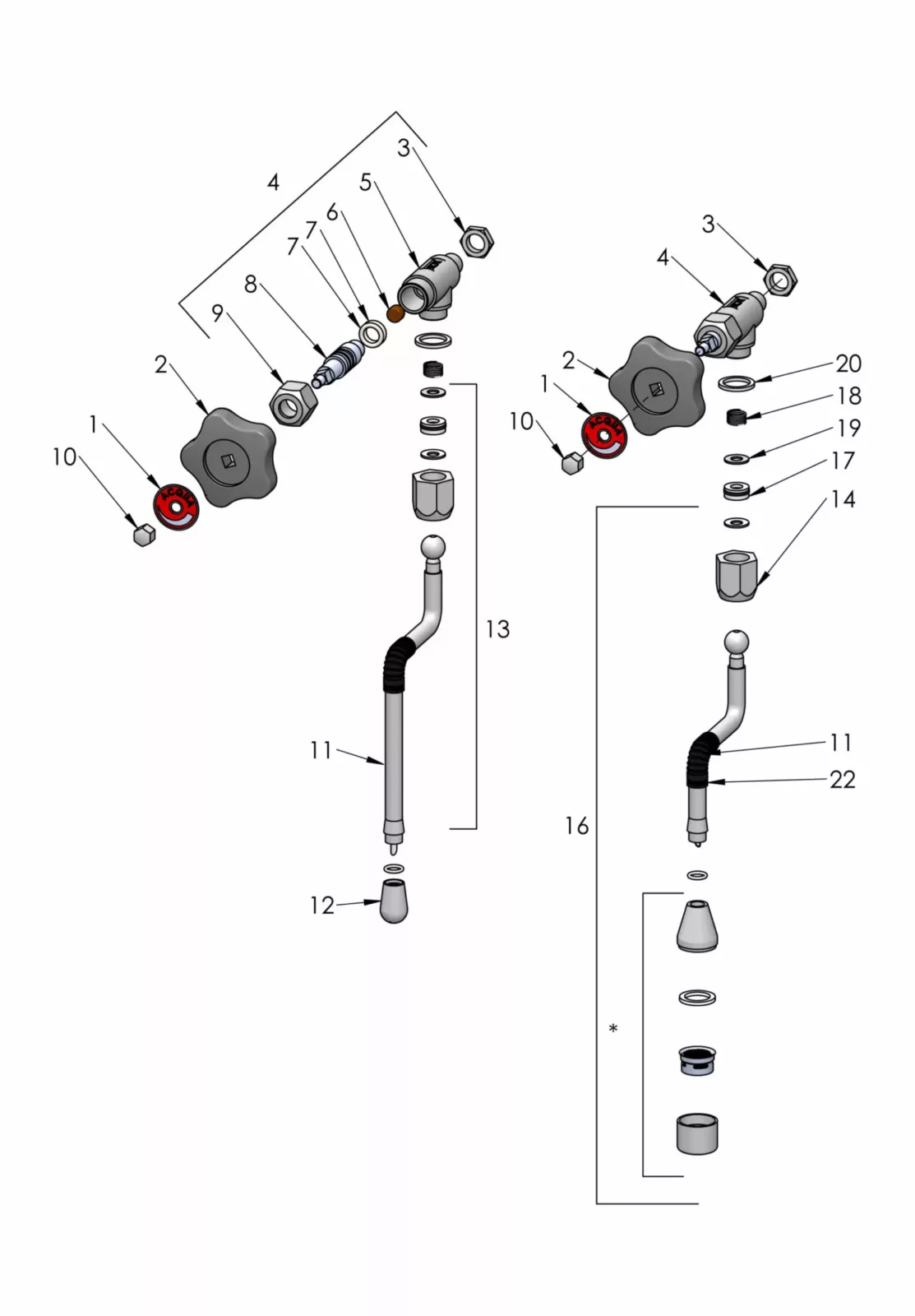

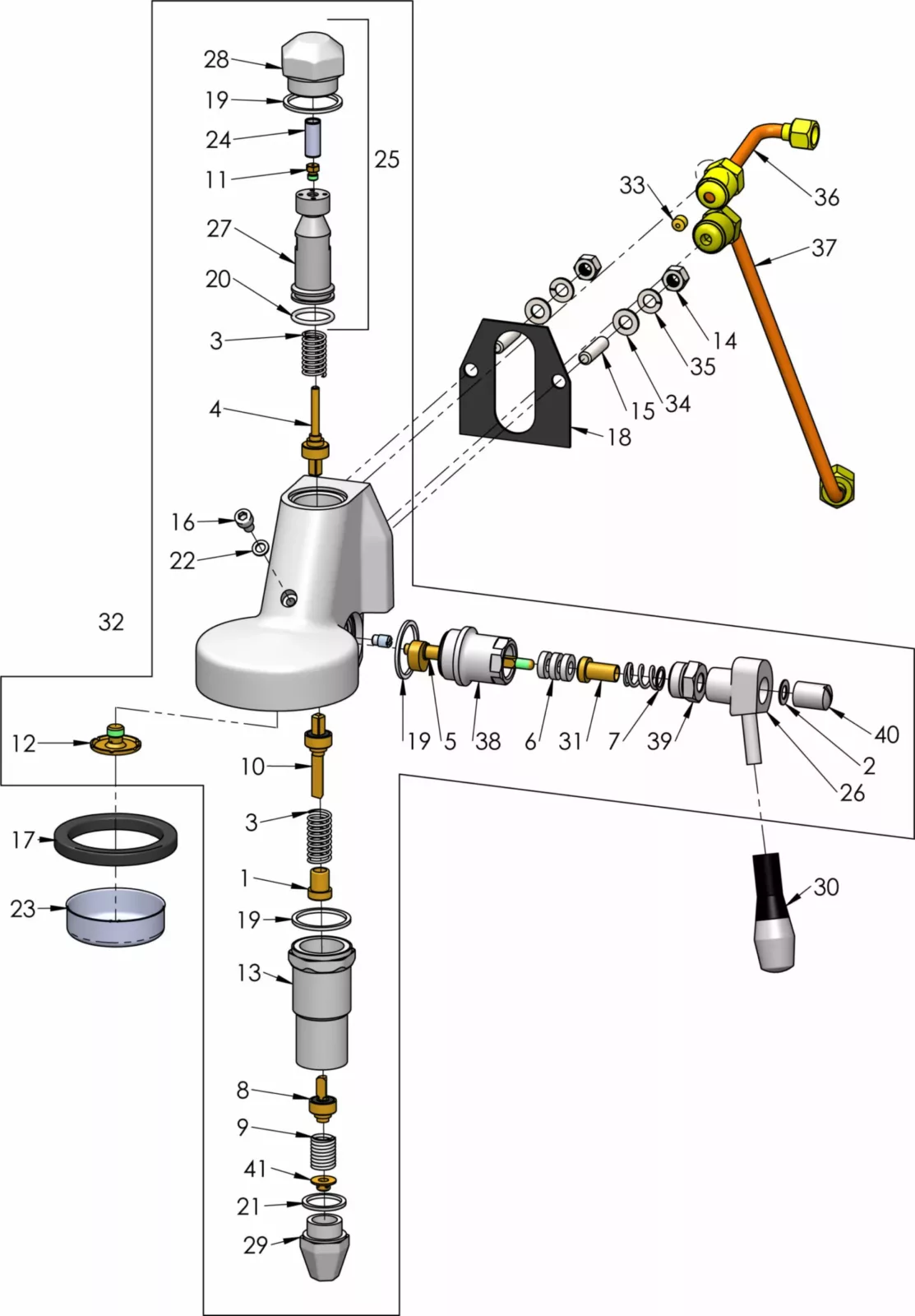

- Please use the parts diagrams provided below to determine the part(s) you need. Then use our search box above to find the part(s) on our website. If no results come up, more than likely we do not stock the part.

- If uncertain, please go to the equipment model or part product page. Then use the Q&A tab found on that web page to ask your question.

- Lastly, and only if the first 2 options were exhausted, please use our parts inquiry page.

- Our call center does not have the training to handle parts inquiries for over 60,000 different parts items. Asking any questions regarding parts will more than likely result in you being referred to the above steps.

- Please note also that all parts purchases are non-returnable or refundable and do not include technical support, instructions, or warranties as the purchase price of any part does not cover the cost of technical support. Technical support is available for repairing equipment in our shop.

- Sorry, we will only special order a part for a model we carry AND was purchased through our supply chain.

- Since we are unaware of the mechanical, electrical, and/or plumbing expertise of a parts buyer or the tools owned by a parts buyer, we are never able to advise if a self-repair can be performed.

| # | SKU |

| 1 | B5220818.1 |

| 2 | B7474212 |

| 3 | B7474216.1 |

| 4 | E81000 |

| 5 | P1984 |

| 6 | P1998 |

| 7 | P2006 |

| 8 | P2007 |

| 9 | P3001.6 |

| 10 | P3002 |

| 11 | P7029 |

| 12 | P9001 |

| 13 | P9003 |

| 14 | P9004 |

| 15 | P9009 |

| 16 | P9016 |

| 17 | P9017 |

| 18 | P9018 |

| 19 | P9028 |

| 20 | P9029 |

| 21 | P9030 |

| # | SKU |

| 1 | B5471509 |

| 2 | B7432517 |

| 3 | B7496076 |

| 4 | C199900275 (230V, 50Hz) |

| 4 | US1005 (110V, 60Hz) |

| 5 | C199900280 (230V, 50Hz) |

| 5 | US1001 (120V, 60Hz) |

| 5 | US1025 (100V) |

| 6 | C199900969 |

| 7 | C229900518 |

| 8 | C229900520 |

| 9 | C229900548 |

| 10 | C229900579 |

| 11 | C229900703 |

| 12 | C249900770 |

| 13 | C439900695 |

| 14 | C499900769 |

| 15 | P2006 |

| 16 | P2009 |

| 17 | P2019 |

| 18 | P2064 |

| 19 | P3006.K |

| 20 | P3019 |

| 21 | P6016 |

| 22 | P6020.3 |

| 23 | P6020.K3 |

| 24 | P6020.K4 |

| 25 | P6020.NK |

| 26 | P6021 |

| 27 | P6022 |

| 28 | P6023 |

| 29 | P6025 |

| 30 | P6047 |

| 31 | P6051 |

| 32 | P7000 |

| 33 | P8016 |

| 34 | P9007 |

| 35 | P9010 |

| 36 | P9010.K1 |

| 37 | P9400 |

| 38 | P9401 |

| 39 | P6020 |

| 40 | P6017 |

| # | SKU |

| 1 | B7400902 |

| 2 | B7432516 |

| 3 | C199900214 |

| 4 | C199900294 |

| 5 | C199901550.1 |

| 6 | C219900561 |

| 7 | C229900393 |

| 8 | C229900518 |

| 9 | C229900520 |

| 10 | C229900525 |

| 11 | C229900559 |

| 12 | C229900740 |

| 13 | C309900127.2 |

| 14 | P2006 |

| 15 | P2009 |

| 16 | P2011 |

| 17 | P2045 |

| 18 | P7014.1 (230V) |

| 18 | US1000 (110V) |

| 19 | P7049 |

| 20 | P7080 |

| 21 | P9013 |

| 22 | P9402 |

| 23 | P9403 |

| 24 | P9404 |

| # | SKU |

| 1 | B5522056.1 |

| 2 | B7371509 |

| 3 | C329900682 |

| 4 | P6000 |

| 5 | P6000.1 |

| 6 | P6000.2 |

| 7 | P6000.3 |

| 8 | P6000.4 |

| 9 | P6000.5 |

| 10 | P6000.6 |

| 11 | P6002.1 |

| 12 | P6002.4 (2-hole) |

| 12 | P6002.7 (3-hole) |

| 12 | P6002.6 (4-hole) |

| 12 | P6002.3 (5-hole) |

| 13 | P6005 |

| 14 | P6005.5 |

| 15 | P6005.6 |

| 16 | P6006 |

| 17 | P6010 |

| 18 | P6011 |

| 19 | P6012 |

| 20 | P6015 |

| 21 | P6002.2 |

| 22 | P6002.2 |

| 23 | P6001.1 |

| 24 | P6001.2 |

| # | SKU |

| 1 | B7479942 |

| 2 | B7479947 |

| 3 | C219900423 |

| 4 | C219900424 |

| 5 | C219900425 |

| 6 | C219900426 |

| 7 | C219900427 |

| 8 | C219900430 |

| 9 | C219900431 |

| 10 | C219903081 |

| 11 | C229900549 |

| 12 | C229901128 |

| 13 | C229901165 |

| 14 | C309900127.2 |

| 15 | C309900131 |

| 16 | C309900164 |

| 17 | C449900229 |

| 18 | C449900767 |

| 19 | C469900421 |

| 20 | C469900422 |

| 21 | C469900783 |

| 22 | C469901132 |

| 23 | C519900103 |

| 24 | C619900554 |

| 25 | P1000.1 |

| 26 | P1000.2 |

| 27 | P1000.3 |

| 28 | P1000.4 |

| 29 | P1000.5 |

| 30 | P1002 |

| 31 | P1004 |

| 32 | P1009 |

| 33 | P1910.1 |

| 34 | P2010 |

| 35 | P2011 |

| 36 | P9405 |

| 37 | P9406 |

| 38 | R000002142 |

| 39 | R000002144 |

| 40 | R000002146 |

| 41 | R000002148 |

| # | SKU |

| 1 | 89424 |

| 2 | 89425 |

| 3 | B5221875CM |

| 4 | B7633617 |

| 5 | B7633618 |

| 6 | C199900087 |

| 7 | C199900306 |

| 8 | C199900957 (DE) |

| 8 | P2034 (US) |

| 8 | P2035 (UK) |

| 8 | P2036 (AU) |

| 9 | C619900098 |

| 10 | C619900104 |

| 11 | C619900105 |

| 12 | C619900106 |

| 13 | C639900764 |

| 14 | M2004 (240V) |

| 14 | US1004 (115V) |

| 15 | P2001 |

| 16 | P2002 |

| 17 | P2006 |

| 18 | P2009 |

| 19 | P2070 |

| 20 | P2591 |

| 21 | P6029 |

| 22 | P9019 |

| 23 | R210 |

Be the first to review “DISCONTINUED ECM Mechanika V Slim Espresso Machine” Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Ask a question

Please ask follow up questions as a new question. Submitted questions will be first reviewed, answered, and lastly publicized.

-

Looking to purchase ECM portafilters part # 89472 (dual spout, angled), and part # 89476 (bottomless, angled). Do you carry these ECM optional parts?

-

Q Looking to purchase ECM portafilters part # 89472 (dual spout, angled), and part # 89476 (bottoml...... Read more answer nowAsked by Anthony on November 29, 2021 1:40 pmAnswered by the admin

Sorry, we do not stock these at this time.

Hi, just wondering if you had an ETA on when the ECM Mechnika V Slim might be back in stock. Thanks!

-

Q Hi, just wondering if you had an ETA on when the ECM Mechnika V Slim might be back in stock. Thanks! answer nowAsked by doug on August 16, 2021 2:03 pmAnswered by the admin Sorry, we have placed our order, but there is no ETA provided by ECM. If you can not wait, we do have other makes or models, but those are selling out quickly.

What grease do you recommend for regreasing the E-61 lever? I backflush with water daily and with the solution once a week. I am nearing the 6-month point at which point i think i will need to regrease.

-

Q What grease do you recommend for regreasing the E-61 lever? I backflush with water daily and with...... Read more answer nowAsked by Payne Griffin on July 8, 2021 4:36 pmAnswered by the admin

PetrolGel.

I think I've settled on getting an HX machine. And i'm leaning toward the mechanika slim. What are your thoughts on this ecm vs other HX models/brands?

-

Q I think I've settled on getting an HX machine. And i'm leaning toward the mechanika slim. What ar...... Read more answer nowAsked by william on June 9, 2021 2:17 pmAnswered by the admin The Slim has a huge boiler for lots of steaming. However, larger boilers are more prone to require greater cooling flushes due to overheating at the grouphead. Every machine has tradeoffs based on usage. Hence, if steaming large amounts of milk, then the SLIM is a perfect fit.

After the machine is on for a while and even after successfully making coffee with it, you can walk up to it and see the boiler pressure gauge has dropped to around the 1 bar mark, from it’s normal 1.5 bar. Open the steam wand valve and the pressure further drops and does not attempt to recover. Cannot hear the boiler relay clicking on anymore and cannot hear the boiler heating back up. Orange light is still lit.

Must turn the power switch off, wait five minutes and turn it back on and that seems to work to put the machine back in operation with the pressure gauge going back to 1.5 bar……until it happens again.

1. Replaced Vacuum relief valve. Did not fix the issue

2. Jumpered both thermostats on top of the boiler. Did not fix the issue

3. Pulled the wire off the water level probe, this caused the pump to turn on and the orange light to turn off. This probe is ok as is the boiler water level

4. Pulled water tank out from the machine, orange front panel light goes out which indicates the tank water level switch is working

5. The label on the top of the Brain box looks like it has gotten very hot and has turned color. Is this normal?

-

Q After the machine is on for a while and even after successfully making coffee with it, you can wa...... Read more answer nowAsked by Don on May 10, 2021 5:14 pmAnswered by the admin

Sounds like a new brain unit is needed. However, no guarantees and parts are non-refundable and non-returnable purchases as there is no way for us to check if an electrical part was damaged upon install.

Need to replace ECM Technika IV broken portafilter # 89425 with 2 spigots (2 cups) I appreciate your confirming that this is the correct portafilter for my machine & price. Thank you for your assistance.

-

Q Need to replace ECM Technika IV broken portafilter # 89425 with 2 spigots (2 cups) I appreciate y...... Read more answer nowAsked by EnriqueE45414 on September 17, 2020 4:40 amAnswered by the admin

This seems to be the incorrect part. We show this portafilter.

I am noticing a persistent hissing when I run my machine. The hissing is getting worse. The machine is still holding pressure and I am able to use it, however I think it now needs to heat more often.

-

Q I am noticing a persistent hissing when I run my machine. The hissing is getting worse. The machi...... Read more answer nowAsked by Daniel on June 5, 2020 3:44 pmAnswered by the admin

This problem is usually the result of limescale build up on the bleeder valve (which we have found on this machine) to not allow it to close the valve upon warm up. It is probably this because of the hissing. Take off the top cover and inspect for steam leaking from the inside.

OR

The other problem is overheating of the boiler caused by limescale inside the pressurstat or its pipe. This has more of a locomotive sound with the boiler pressure gauge (not pump pressure) over 2 bar.

Diagrams for the Mechanika Slim espresso machine should be reviewed to learn the inside of the machine. Please note the manufacturers do not cover limescale issues under warranty as it is a water defect.

just curious on the timeline when these will be back in stock?

-

Q just curious on the timeline when these will be back in stock? answer nowAsked by dustinmaust on July 11, 2019 7:20 pmAnswered by the admin

These are just leaving Germany, so we re estimating 4-6 weeks depending upon a lot of variables.

I am not sure exactly how to get the screen down since there is nothing to really hold it in place. This is my first espresso machine with an E61 grouphead, so it is something I am becoming more familiar with.

-

Q I am not sure exactly how to get the screen down since there is nothing to really hold it in plac...... Read more answer nowAsked by Lindley Jones on May 10, 2019 6:45 pmAnswered by the admin

Thank you for your inquiry. Please only remove the dispersion screen when replacing. Otherwise, backflush as indicated.

A friend has a Bezzera BZ10 and has been very happy, esp with the quick 10-min warm up time. I'm wondering if the warm up time on the ECM Mechanika Slim (or similar E61 head) is significantly greater? I know I can put a machine on a timer for the morning, but it's nice to be able to serve a drink when friends pop over...Is the BZ10 a clear winner, or is the difference only minutes?

-

Q A friend has a Bezzera BZ10 and has been very happy, esp with the quick 10-min warm up time. I'm ...... Read more answer nowAsked by Christopher Gibson on January 9, 2019 4:16 pmAnswered by the admin

The Mechanika Slim needs a good 20-30 minutes to warm up. Please note after a timer you need to plug in a surge suppressor 1080 joules or higher because we have seen timers cause damage to the electrical components inside espresso machines.

The BZ10 with a Bezzera grouphead warms up in usually 10-15 minutes. A similar machine for warm up within 15-20 miutes with an E61 grouphead is the Lelit Mara.

Reviews

There are no reviews yet.