ECM Elektronika II Profi HX Switchable Espresso Machine

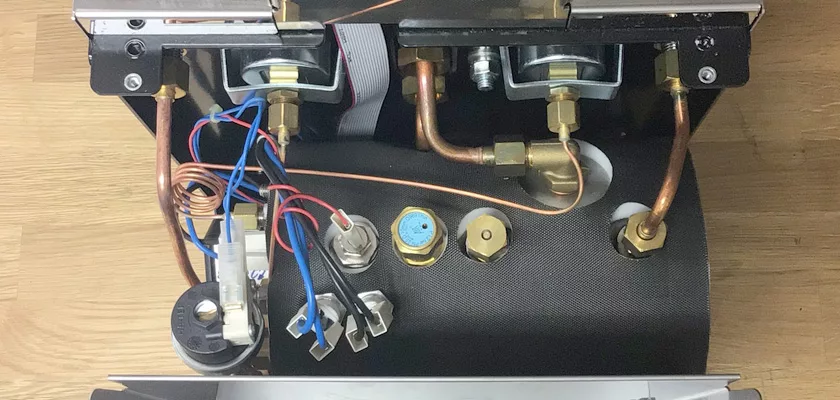

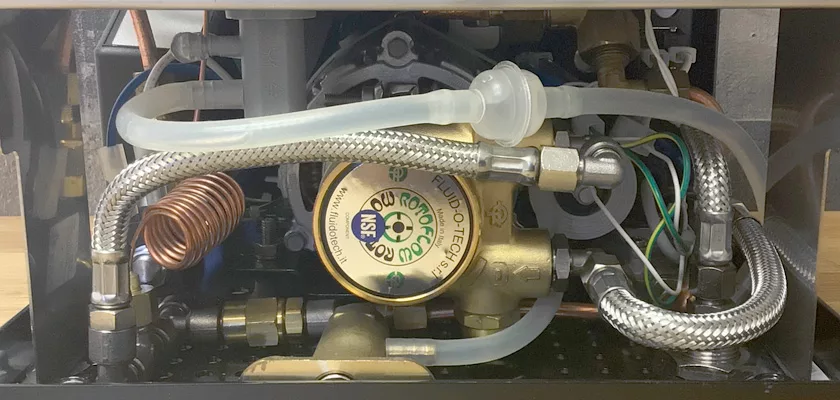

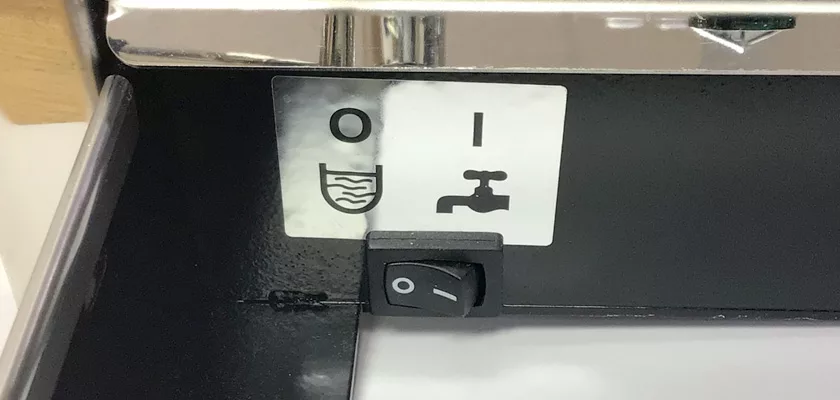

The ECM Elektronika II Profi has the same quality features as the Technika such as an E61 grouphead and rotary vane pump. In addition, the Elektronika has a row of programmable buttons that dose out a preset amount of water. You can also connect to a direct water line so you won’t have to constantly fill a water tank.