Introducing the Nurri L-Type Espresso Machine: Elevate Your Home Brewing Experience!

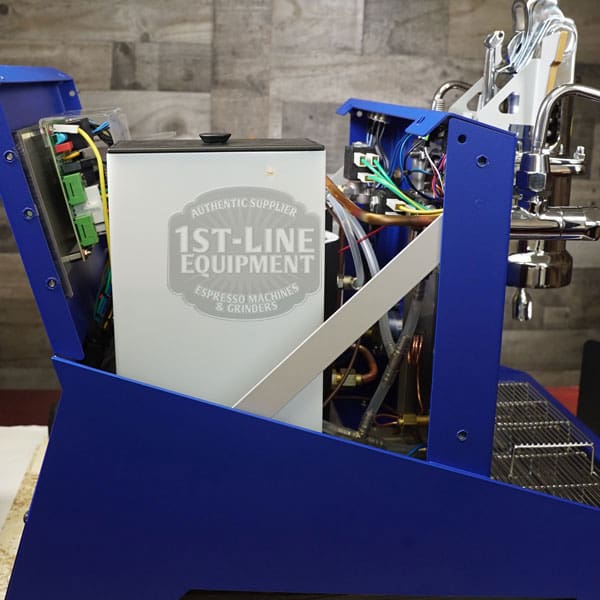

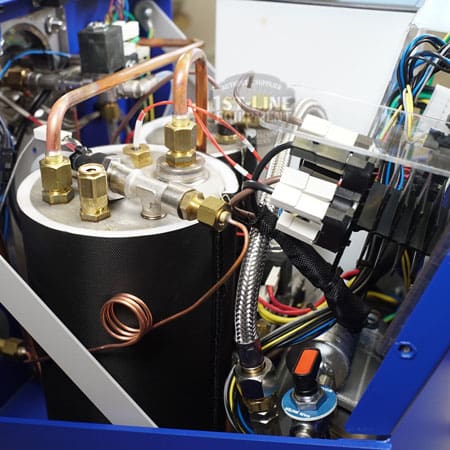

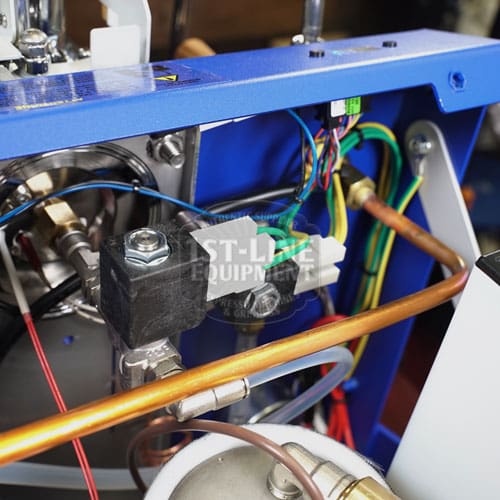

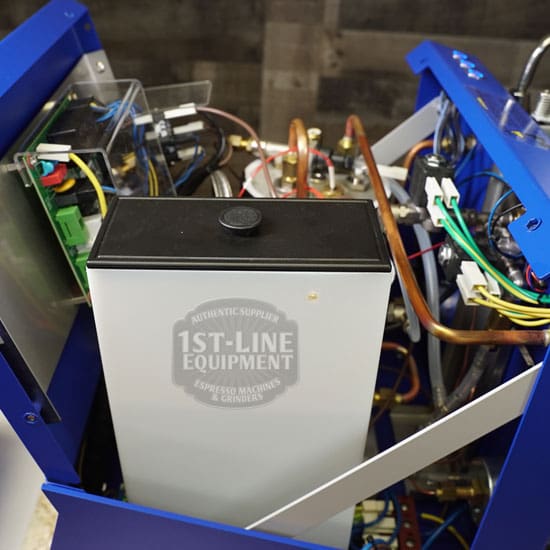

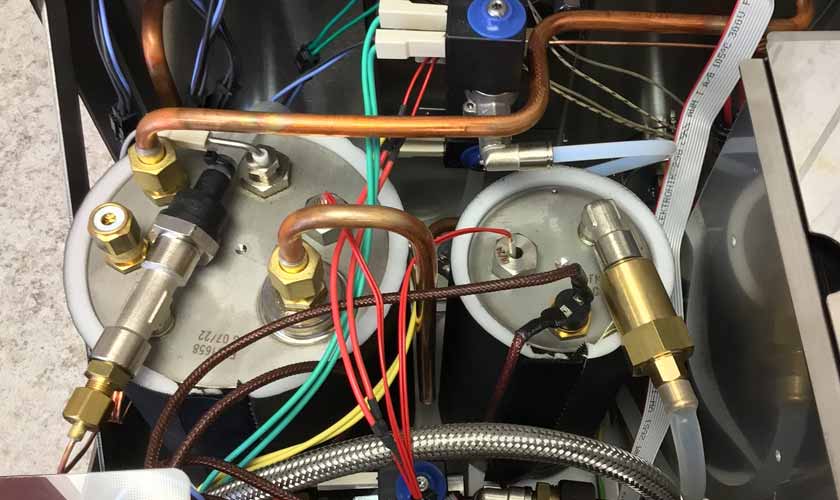

Unleash your inner barista with the Nurri L-Type Espresso Machine, a masterpiece of engineering designed for the coffee aficionado. Imagine savoring the rich aroma of freshly brewed espresso shot after shot, all thanks to its advanced Dual Boiler System. This sophisticated setup ensures simultaneous steaming and brewing, so you can enjoy perfectly textured milk while your espresso is extracted to perfection.

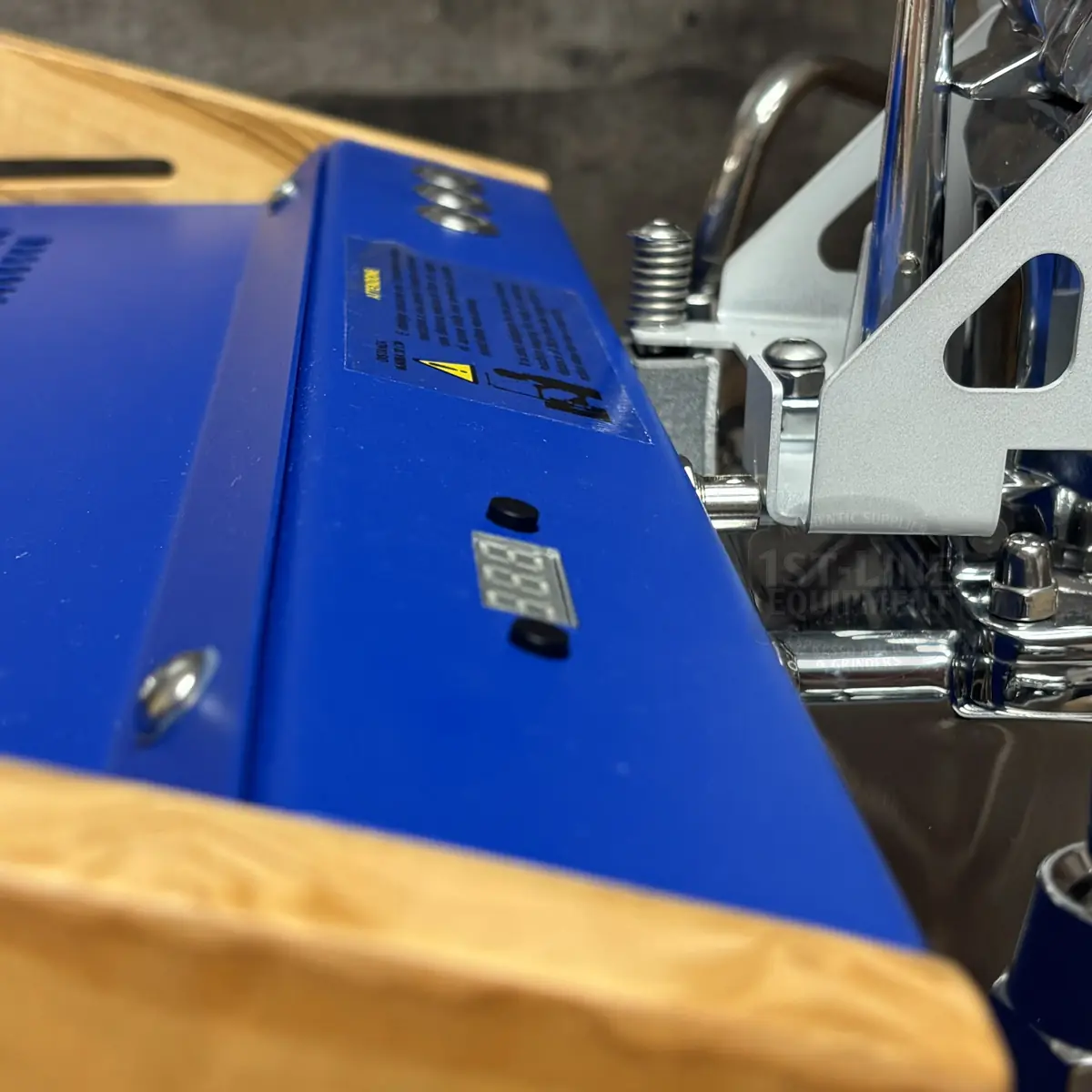

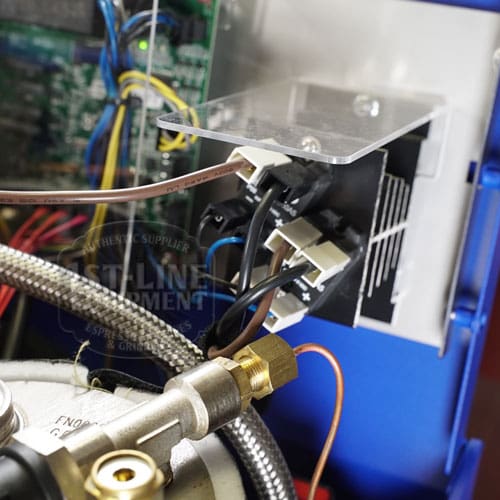

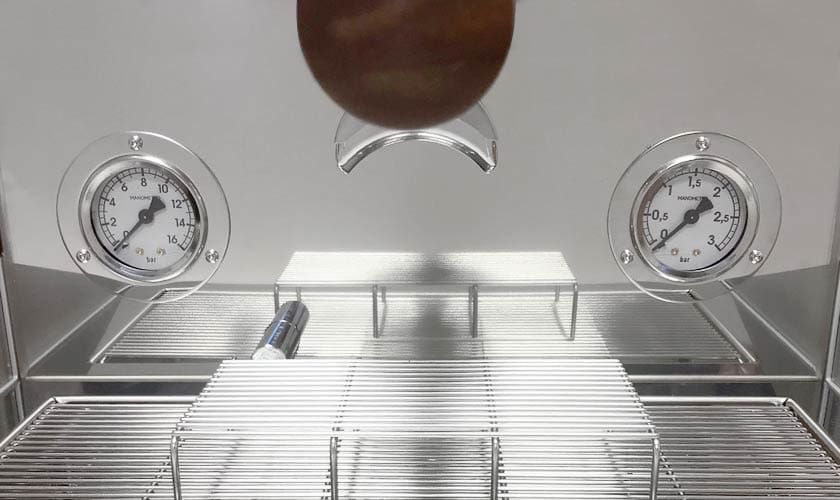

Crafted with precision, the lever extraction mechanism offers you full control over your brewing process. Each pull is an act of art, allowing you to explore the depths of flavor hidden within your coffee beans. The PID controls enhance your experience by maintaining optimal temperature stability, so you achieve consistent results every single time—no more guesswork!

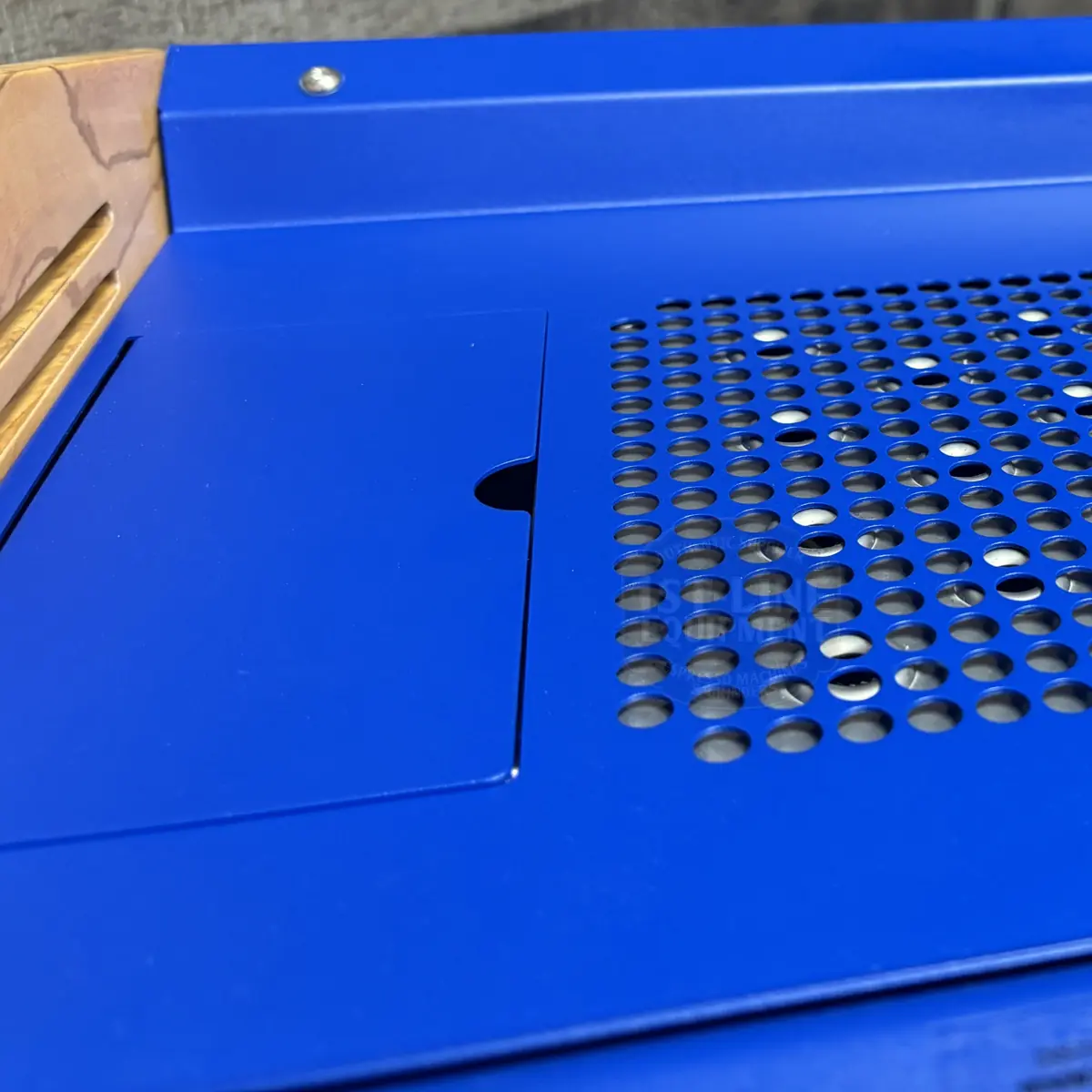

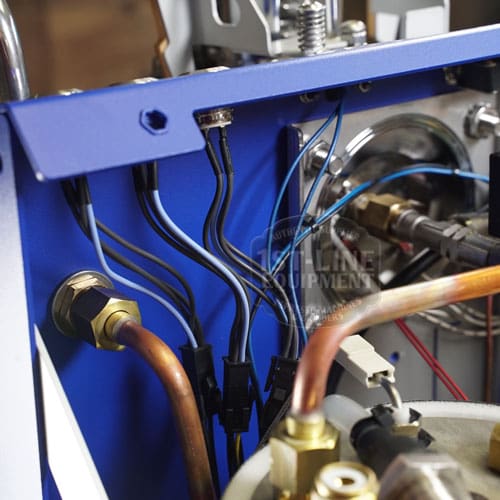

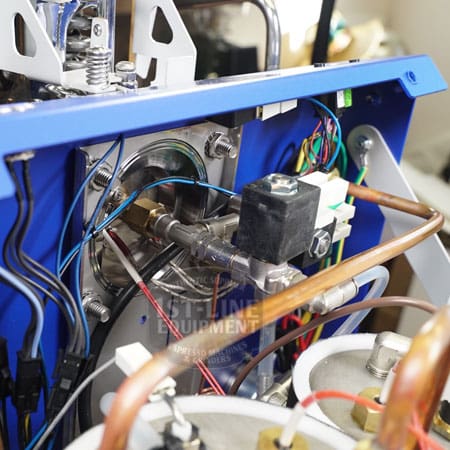

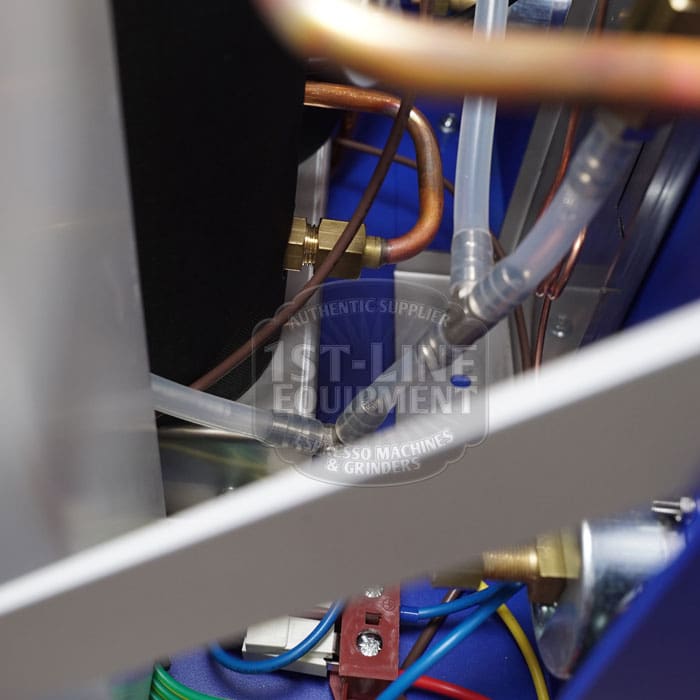

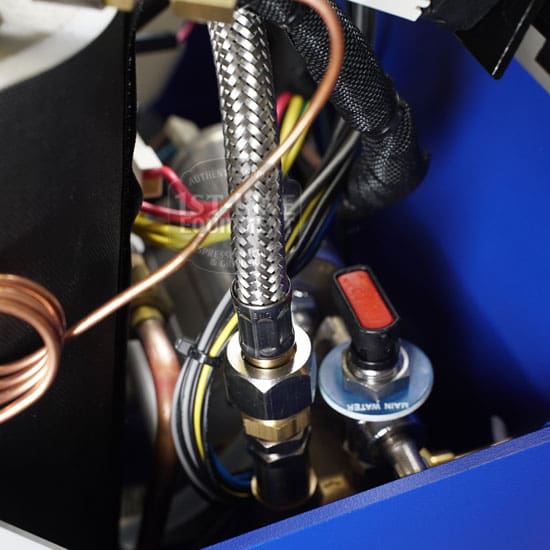

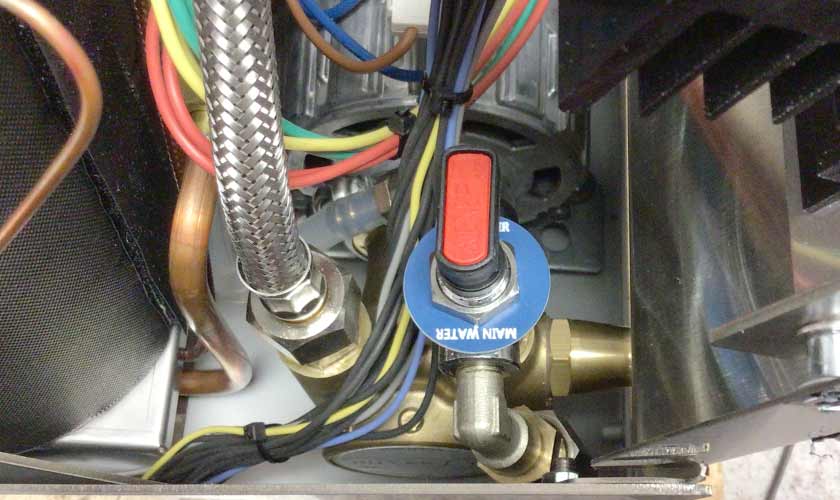

The heart of this machine features a powerful rotary vane pump, ensuring a smooth and silent operation. Couple this with the robust 54mm grouphead equipped with a unique dual paddle system, and you’ll discover brewing bliss. The left paddle releases grouphead pressure, allowing you to remove the portafilter right away. The right paddle efficiently purges the shower screen, making cleanup a breeze.

With three PID sensors strategically placed—one in the coffee boiler, one in the steam boiler, and one in the grouphead—you will have precise temperature control at your fingertips, allowing you to experiment with different brews and techniques like a seasoned barista.

Transform your coffee ritual into a delicious, aromatic journey with the Nurri L-Type Espresso Machine. Whether you’re entertaining guests or indulging in a quiet moment of self-care, this machine offers a blend of innovation and elegance that no true coffee lover should be without. Get ready to elevate your home brewing experience and bring out the best in every cup!