Heat Exchanger Types

A common myth for newcomers to the espresso machine world is that one needs a dual boiler espresso machine to extract espresso and steam/froth milk at the same time. This myth is false. Please read Heat Exchanger vs Double Boiler prior to reading this page.

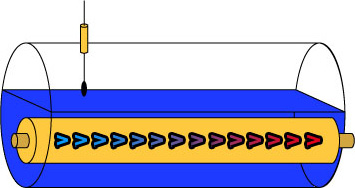

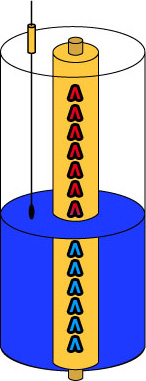

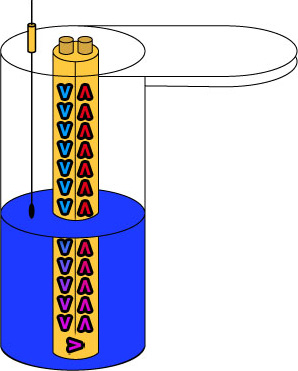

Below are four generic representations of typical heat exchanger systems. Each diagram is a cylinder representing the boiler, either a horizontal orientation or vertical. The blue in the boiler represents the water level. The black line with the yellow sleeve represents the autofill sensor.

The yellow tube(s) that run the length of the boiler is the heat exchanger tube(s). In layman’s terms, the water (blue) heats to the necessary temperature for steam and hot water. (around 150º-170º) The water passing through the heat exchanger tube is significantly colder.

The yellow tube(s) that run the length of the boiler is the heat exchanger tube(s). In layman’s terms, the water (blue) heats to the necessary temperature for steam and hot water. (around 150º-170º) The water passing through the heat exchanger tube is significantly colder.

As this cold water passes through the submerged pipe in the hot water, it absorbs some of the excess heat found in the water. This is what we call the heat exchange.

In the diagram found directly to the right, we see a very basic HX system.

The boiler is half-filled up with water. The autofill sensor ensures that it does not over or under fill. Cold water enters the HX at the bottom and rises upward. As it rises it heats to the proper brew temperature. This is controlled by the speed at which the water flows through the HX. Slower, and it will absorb more heat, faster and it absorbs less.

Immediately after exiting the top of the HX, the water is directed toward the grouphead where it will make contact with your coffee puck.

This style of HX (pictured, right) is found on such espresso machines as the VBM Domobar.

Next, pictured directly below, is the next most common HX type. This style is very similar to that which is found in the VBM with the only difference being the orientation of the boiler. This style- mounted horizontally is found on such machines as the Isomac Tea and Millennium.

This orientation is preferred in some cases because of the fact that the HX tube is almost always 100% covered. In large volume situations, drawing large amounts of hot water or steam can cause the boiler level to drop. Although it refills quickly, this variation in the level of hot water will affect the end temperature of the heat exchanger. By having the HX pipe mounted lower and 100% submerged, you avoid these fluctuations.

The next HX type is represented below, with the dual heat exchanger pipes, running vertically. It is that which is found on larger commercial machines, such as the Elektra Barlume. This style is used on machines with multiple groupheads. Each grouphead will have its own respective heat exchanger.

Like the HXs above, this works by flowing water up from the bottom, flash heating it and exiting it out the top. Because the boiler size is so much larger for machines with multiple groups, horizontal orientation is the more common setup. Also, with the boiler being larger the level of water will not drop as drastically when steaming or pulling hot water.

Lastly is the HX style found in the Bezzera Espresso Machines. (Pictured to the right).

Lastly is the HX style found in the Bezzera Espresso Machines. (Pictured to the right).

This style is unique to Bezzera. The heat exchanger and boiler both have their own style.

The HX here uses a rounded tube. The water enters and exits at the top. The inside, opposite the openings, is rounded off and causes the water to swirl back up inside the HX tube and exit out the top, next to where it entered.

The second unique aspect is the shape of the boiler. These boilers have a plate that sticks outward from the top of them. This is used as a heatsink to help transfer heat to the grouphead.

Because Bezzera does not use an E61 grouphead, or a thermosyphon to heat the group they had to devise a way to heat the grouphead to the proper temperature. The boiler design does just this. As the water in the boiler heats, the heat soaks into the boiler walls, up onto the plate, and down into the grouphead.

Important Note about most HX machines, and all machines with auto-refill probes:

The auto-refill probe works by sending 5 volts into the boiler. The 5 volts enter through the probe, and grounds out when it makes contact with water. When the ground connection is made, the auto-refill stops. If the water level drops, the probe is no longer grounded to the water. Refill starts and goes until the probe makes contact with the water.

If you use distilled or reverse osmosis water:

This water sometimes is purified too much. The probe will not sense that it has made contact with water. If this happens, the boiler will overfill and spray water out of the safety valve located on the top of the boiler.

This is due to reverse osmosis water and distilled water being too pure. We recommend cutting this water with 20% tap water, which will increase the number of minerals in the water to the point where the probe will sense it.

Are you ready to begin your search on the perfect heat exchange espresso machine? Then check out all the different models!

Please note the above information is subject to copyright. It cannot be published by any means without the expressed written consent of 1st-line Equipment, LLC.